Table of Contents

Benefits of Using Powder Filling Machines

Powder filling machines are essential equipment in various industries that deal with powdered products. These machines offer numerous benefits that can significantly improve the efficiency and productivity of a production line. In this article, we will discuss the advantages of using powder filling machines and why they are a valuable investment for businesses.

One of the primary benefits of powder filling machines is their ability to accurately dispense a precise amount of powder into containers. This ensures consistency in product quality and reduces the risk of overfilling or underfilling containers. By using a powder filling machine, businesses can minimize product wastage and save on production costs.

Another advantage of powder filling machines is their speed and efficiency. These machines are designed to fill containers quickly and accurately, allowing businesses to increase their production output and meet customer demands more effectively. With a powder filling machine, companies can streamline their production process and improve overall efficiency.

Powder filling machines also offer versatility in terms of the types of powders they can handle. Whether it is fine powders, granules, or even abrasive materials, these machines are equipped to handle a wide range of products. This flexibility allows businesses to use the same machine for different types of powders, reducing the need for multiple machines and saving on equipment costs.

In addition to accuracy, speed, and versatility, powder filling machines also help improve the safety and hygiene of the production environment. These machines are designed to minimize dust emissions during the filling process, reducing the risk of inhalation and contamination. By using a powder filling machine, businesses can create a cleaner and safer working environment for their employees.

Furthermore, powder filling machines are easy to operate and maintain, making them a user-friendly option for businesses. With simple controls and minimal training required, operators can quickly learn how to use these machines effectively. Additionally, regular maintenance and cleaning of powder filling machines are straightforward, ensuring that they remain in optimal working condition for extended periods.

Overall, powder filling machines offer a range of benefits that can help businesses improve their production processes and enhance product quality. From accuracy and speed to versatility and safety, these machines are a valuable investment for companies looking to optimize their operations and increase efficiency.

In conclusion, powder filling machines are essential equipment for businesses that deal with powdered products. These machines offer numerous benefits, including accuracy, speed, versatility, safety, and ease of use. By investing in a powder filling machine, companies can streamline their production processes, reduce costs, and improve overall efficiency. With their many advantages, powder filling machines are a valuable asset for any business looking to enhance their production capabilities.

Tips for Choosing the Right Powder Filling Machine

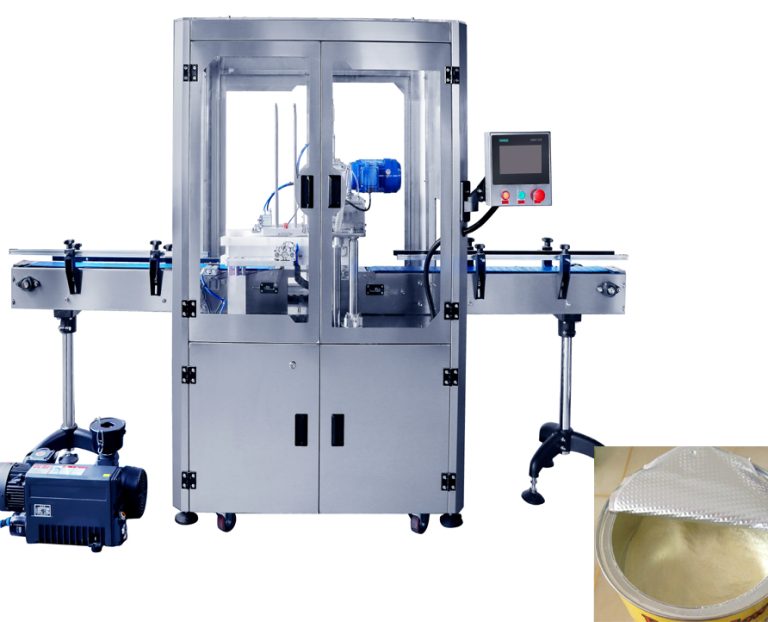

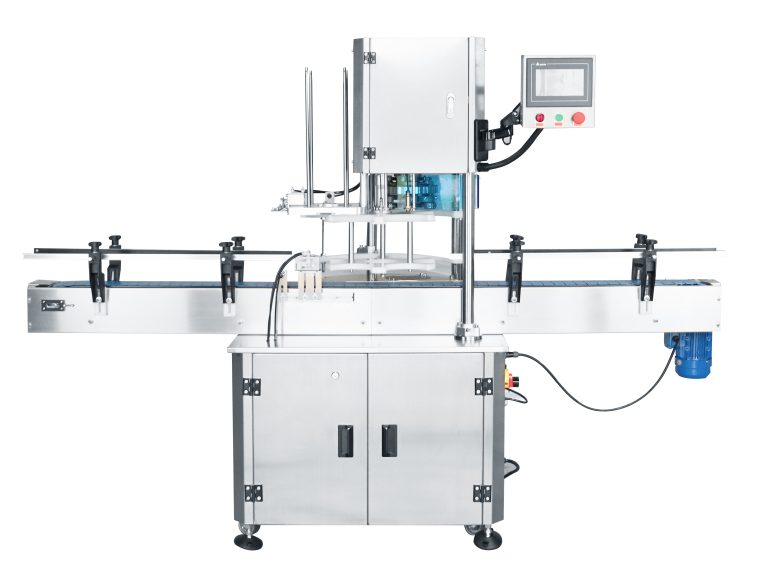

Powder filling machines are essential equipment for businesses in various industries, including pharmaceuticals, food and beverage, cosmetics, and more. These machines are designed to accurately fill containers with powdered substances, such as spices, flour, pharmaceutical powders, and more. Choosing the right powder filling machine is crucial for ensuring efficiency, accuracy, and consistency in your production process. In this article, we will discuss some tips for selecting the right powder filling machine for your business.

First and foremost, it is essential to consider the type of powder you will be filling. Different powders have varying properties, such as density, flow characteristics, and particle size. Some powders may be free-flowing, while others may be sticky or prone to clumping. It is important to choose a powder filling machine that is suitable for the specific characteristics of the powder you will be working with. For example, auger fillers are ideal for filling fine powders, while vibratory fillers are better suited for filling granular powders.

Another important factor to consider when choosing a powder filling machine is the speed and accuracy of the machine. The speed of the machine will determine how quickly you can fill containers, while the accuracy will ensure that each container is filled with the correct amount of powder. It is important to choose a machine that can meet your production requirements in terms of speed and accuracy. Additionally, consider the size and shape of the containers you will be filling, as this will also impact the type of machine you need.

When selecting a powder filling machine, it is also important to consider the level of automation you require. Fully automatic machines are capable of filling, sealing, and labeling containers without the need for manual intervention. Semi-automatic machines, on the other hand, require some level of manual operation. The level of automation you choose will depend on your production volume, budget, and the level of control you require over the filling process.

Furthermore, it is important to consider the maintenance and cleaning requirements of the powder filling machine. Regular maintenance is essential for ensuring the longevity and efficiency of the machine. Look for machines that are easy to clean and maintain, as this will help reduce downtime and ensure consistent performance. Additionally, consider the availability of spare parts and technical support for the machine you choose.

In conclusion, choosing the right powder filling machine is essential for ensuring efficiency, accuracy, and consistency in your production process. Consider the type of powder you will be filling, the speed and accuracy of the machine, the level of automation required, and the maintenance and cleaning requirements when selecting a powder filling machine. By taking these factors into consideration, you can choose a machine that meets your production requirements and helps you achieve your business goals.