Table of Contents

Benefits of Using an Automatic Roller Wheel Capping Machine

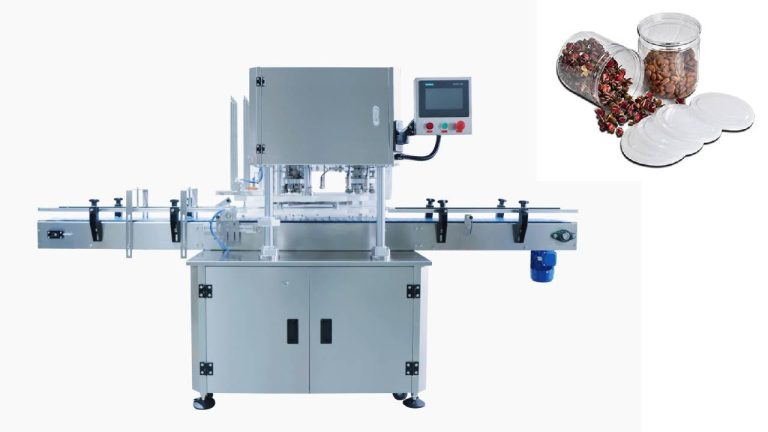

Automatic roller wheel capping machines have revolutionized the packaging industry by providing a fast and efficient way to cap jars with ease. These machines are equipped with an auto cap feeder, which eliminates the need for manual labor and increases productivity. In this article, we will explore the benefits of using an automatic roller wheel capping machine for jars with an auto cap feeder.

One of the main advantages of using an automatic roller wheel capping machine is its speed and efficiency. These machines are capable of capping hundreds of jars per minute, significantly reducing the time and labor required for the packaging process. This increased speed allows companies to meet high production demands and fulfill orders in a timely manner.

In addition to speed, automatic roller wheel capping machines also ensure consistent and precise capping results. The roller wheels are designed to apply the perfect amount of pressure to secure the caps onto the jars, preventing leaks and ensuring product freshness. This level of precision is difficult to achieve with manual capping methods, making automatic roller wheel capping machines a reliable choice for companies looking to maintain product quality.

Furthermore, the auto cap feeder feature of these machines further enhances their efficiency. The feeder automatically supplies caps to the capping head, eliminating the need for operators to manually place caps onto jars. This not only saves time but also reduces the risk of human error, ensuring that each jar is capped correctly every time.

Another benefit of using an automatic roller wheel capping machine is its versatility. These machines are capable of capping jars of various shapes and sizes, making them suitable for a wide range of products. Whether you are packaging food items, cosmetics, or pharmaceuticals, an automatic roller wheel capping machine can accommodate your needs.

Moreover, automatic roller wheel capping machines are easy to operate and maintain. They are equipped with user-friendly controls that allow operators to adjust settings and monitor the capping process with ease. Additionally, these machines are built to withstand the rigors of continuous use, requiring minimal maintenance to keep them running smoothly.

In conclusion, the benefits of using an automatic roller wheel capping machine for jars with an auto cap feeder are numerous. From increased speed and efficiency to consistent and precise capping results, these machines offer a reliable solution for companies looking to streamline their packaging process. With their versatility and ease of operation, automatic roller wheel capping machines are a valuable asset for any packaging operation.

How to Choose the Right Automatic Roller Wheel Capping Machine for Your Jar Packaging Needs

When it comes to packaging products in jars, having the right capping machine is essential to ensure a secure and efficient seal. One popular option for jar capping is the automatic roller wheel capping machine with an auto cap feeder. This type of machine is designed to streamline the capping process by automatically feeding caps onto the jars and applying them with precision using roller wheels. If you are in the market for an automatic roller wheel capping machine for your jar packaging needs, there are a few key factors to consider to ensure you choose the right machine for your specific requirements.

One of the first things to consider when choosing an automatic roller wheel capping machine is the size and shape of your jars. These machines are typically designed to accommodate a range of jar sizes, but it is important to ensure that the machine you choose can handle the specific dimensions of your jars. Additionally, consider the type of caps you will be using on your jars, as different machines may be designed to work with specific cap sizes and styles.

Another important factor to consider when choosing an automatic roller wheel capping machine is the speed and efficiency of the machine. Depending on the volume of jars you need to cap, you may require a machine that can cap a high number of jars per minute. Look for a machine that offers adjustable speed settings to accommodate your production needs. Additionally, consider the overall efficiency of the machine, including its ease of use and maintenance requirements.

In addition to size, shape, and speed, it is also important to consider the overall quality and reliability of the automatic roller wheel capping machine. Look for a machine that is constructed from durable materials and is designed to withstand the rigors of continuous use in a production environment. Additionally, consider the reputation of the manufacturer and look for machines that come with a warranty to protect your investment.

When choosing an automatic roller wheel capping machine, it is also important to consider any additional features or capabilities that may be beneficial for your specific packaging needs. Some machines may offer features such as automatic height adjustment, cap detection sensors, or integrated labeling systems. Consider your specific requirements and look for a machine that offers the features that will help streamline your packaging process.

In conclusion, choosing the right automatic roller wheel capping machine for your jar packaging needs requires careful consideration of factors such as jar size, cap type, speed, efficiency, quality, and additional features. By taking the time to evaluate your specific requirements and research the options available, you can select a machine that will help streamline your packaging process and ensure a secure seal on your jars. With the right automatic roller wheel capping machine, you can increase efficiency, reduce labor costs, and improve the overall quality of your packaged products.

Tips for Maintaining and Troubleshooting an Automatic Roller Wheel Capping Machine

Automatic roller wheel capping machines are a popular choice for businesses looking to streamline their packaging process. These machines are designed to efficiently cap jars with ease, thanks to their automatic roller wheel mechanism. However, like any piece of equipment, regular maintenance and troubleshooting are essential to ensure the machine operates smoothly and efficiently.

One of the most important tips for maintaining an automatic roller wheel capping machine is to regularly clean and lubricate the machine. Over time, dust, debris, and residue from the jars can build up on the machine, causing it to operate less efficiently. By regularly cleaning the machine and applying lubricant to the moving parts, you can prevent this buildup and ensure the machine continues to function properly.

In addition to regular cleaning and lubrication, it is also important to regularly inspect the machine for any signs of wear or damage. Check the roller wheels, belts, and other moving parts for any signs of wear or damage, and replace them as needed. By catching and addressing any issues early on, you can prevent more serious problems from occurring down the line.

Another important tip for maintaining an automatic roller wheel capping machine is to calibrate the machine regularly. Over time, the machine may become misaligned, causing it to cap jars incorrectly. By calibrating the machine regularly, you can ensure that it continues to cap jars accurately and efficiently.

When it comes to troubleshooting an automatic roller wheel capping machine, one of the first things to check is the cap feeder. The cap feeder is responsible for supplying caps to the machine, and if it is not functioning properly, the machine will not be able to cap jars. Check the cap feeder for any jams or blockages, and clear them as needed. If the cap feeder is still not working properly, it may need to be replaced.

If the cap feeder is not the issue, the next thing to check is the roller wheels. The roller wheels are responsible for capping the jars, and if they are not aligned properly, the machine will not be able to cap jars correctly. Check the alignment of the roller wheels and adjust them as needed. If the roller wheels are damaged or worn, they may need to be replaced.

If the cap feeder and roller wheels are not the issue, the next thing to check is the motor. The motor is responsible for powering the machine, and if it is not functioning properly, the machine will not be able to cap jars. Check the motor for any signs of wear or damage, and replace it if necessary.

In conclusion, maintaining and troubleshooting an automatic roller wheel capping machine is essential to ensure it continues to operate efficiently. By following these tips and regularly inspecting and maintaining the machine, you can prevent issues from occurring and keep your packaging process running smoothly.