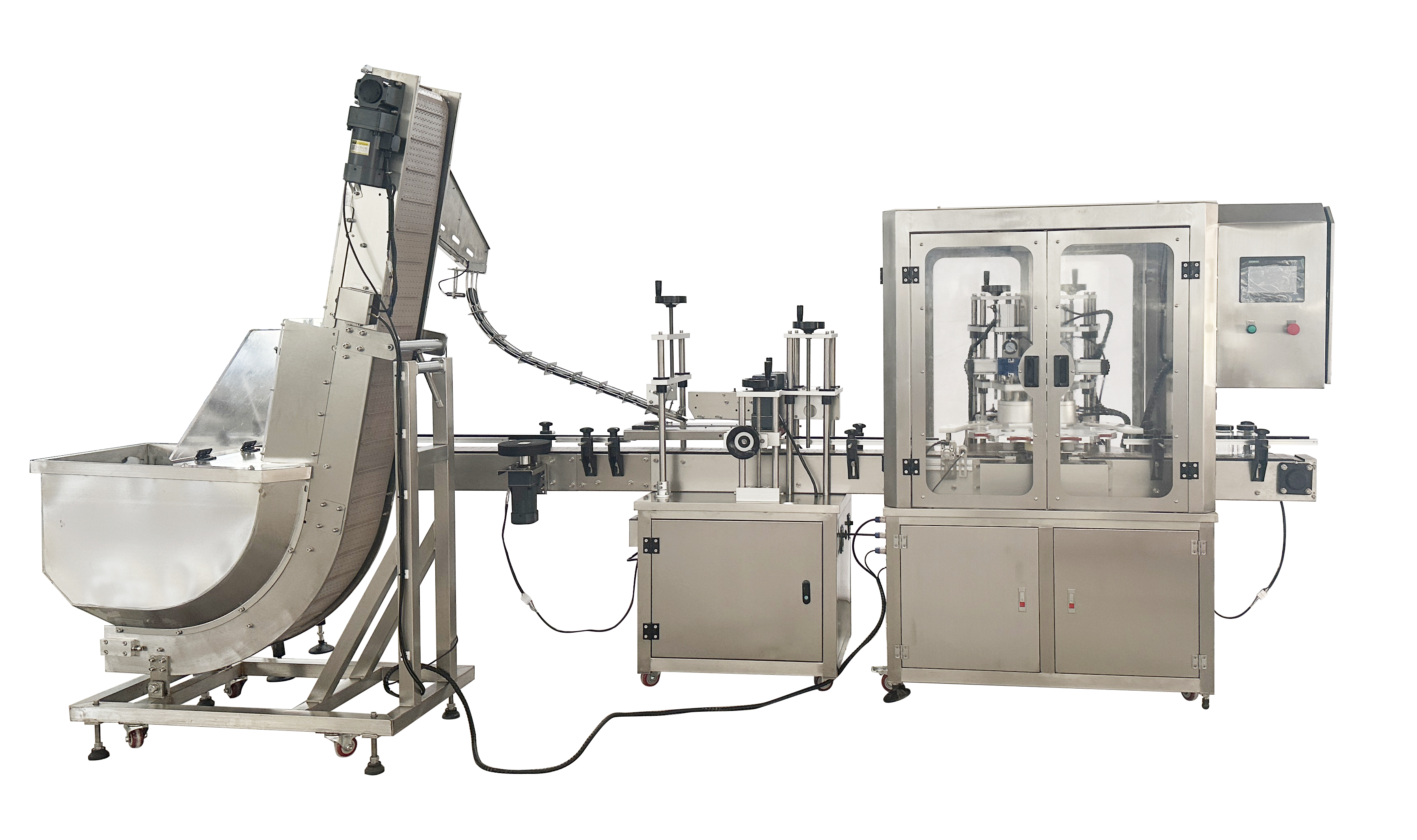

Benefits of Using an Automatic Dual Head Vacuum Capper for Glass Jars with Cap Hoist

When it comes to packaging products in glass jars, ensuring a tight seal is crucial to maintaining product freshness and quality. One of the most effective ways to achieve this is by using an automatic dual head vacuum capper with a cap hoist. This innovative piece of equipment offers a range of benefits that can streamline the packaging process and improve overall efficiency.

One of the key advantages of using an automatic dual head vacuum capper is its ability to cap multiple jars simultaneously. This not only speeds up the packaging process but also ensures consistency in the tightness of the seal on each jar. By capping multiple jars at once, manufacturers can significantly increase their production output without sacrificing quality.

In addition to its speed and efficiency, an automatic dual head vacuum capper also offers a high level of precision when applying caps to glass jars. The capper is equipped with sensors that can detect the exact position of each jar, ensuring that the cap is applied accurately and securely. This level of precision helps to minimize the risk of leaks or contamination, which can be costly and damaging to a brand’s reputation.

Furthermore, the cap hoist feature of the automatic dual head vacuum capper eliminates the need for manual handling of caps, reducing the risk of contamination and ensuring a hygienic packaging process. The cap hoist lifts caps from a designated area and places them onto the jars with precision, eliminating the risk of human error and ensuring a consistent seal on each jar.

Another benefit of using an automatic dual head vacuum capper is its versatility. The capper can be easily adjusted to accommodate different jar sizes and cap types, making it suitable for a wide range of products. This flexibility allows manufacturers to use the same equipment for various packaging needs, saving time and resources that would otherwise be spent on switching between different machines.

In addition to its practical benefits, an automatic dual head vacuum capper also offers financial advantages for manufacturers. By increasing production output and minimizing the risk of product spoilage, the capper helps to reduce operational costs and improve overall profitability. The efficiency and precision of the capper also contribute to a higher quality end product, which can lead to increased customer satisfaction and loyalty.

Overall, the benefits of using an automatic dual head vacuum capper for glass jars with cap hoist are clear. From increased production output and efficiency to improved product quality and consistency, this innovative piece of equipment offers a range of advantages that can help manufacturers streamline their packaging process and enhance their bottom line. By investing in a dual head vacuum capper, manufacturers can take their packaging operations to the next level and stay ahead of the competition in today’s fast-paced market.