Benefits of Using an Automatic Liquid Filling Line for Glass Bottles

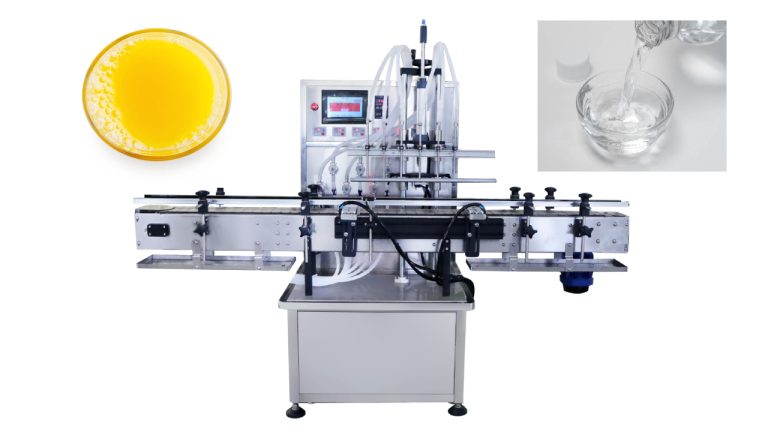

In the manufacturing industry, efficiency and accuracy are key factors in ensuring the success of a production line. When it comes to filling glass bottles with liquid products, using an automatic liquid filling line can provide numerous benefits that can streamline the production process and improve overall productivity.

One of the main advantages of using an automatic liquid filling line for glass bottles is the speed at which it can fill bottles. These machines are designed to fill multiple bottles simultaneously, significantly reducing the time it takes to fill a large number of bottles compared to manual filling methods. This increased speed can help manufacturers meet tight production deadlines and increase output without sacrificing quality.

In addition to speed, automatic liquid filling lines also offer a high level of accuracy in filling glass bottles. These machines are equipped with precision controls that ensure each bottle is filled with the exact amount of liquid, eliminating the risk of under or overfilling. This level of accuracy is crucial in industries where consistency and quality control are paramount, such as the pharmaceutical or food and beverage industries.

Another benefit of using an automatic liquid filling line for glass bottles is the reduction in labor costs. By automating the filling process, manufacturers can significantly reduce the number of workers needed to operate the production line. This not only saves on labor costs but also minimizes the risk of human error, resulting in a more efficient and reliable production process.

Furthermore, automatic liquid filling lines are designed to be versatile and adaptable to different bottle sizes and shapes. This flexibility allows manufacturers to easily switch between different products or packaging formats without the need for extensive retooling or adjustments. This versatility can help manufacturers respond quickly to changing market demands and stay competitive in a fast-paced industry.

Additionally, automatic liquid filling lines are equipped with advanced technology that can improve overall product quality. These machines are designed to minimize product waste and spillage, ensuring that each bottle is filled with precision and accuracy. This not only reduces product loss but also helps maintain a clean and hygienic production environment, which is essential in industries where product safety is a top priority.

In conclusion, the benefits of using an automatic liquid filling line for glass bottles are clear. From increased speed and accuracy to reduced labor costs and improved product quality, these machines offer a range of advantages that can help manufacturers streamline their production process and stay ahead of the competition. By investing in an automatic liquid filling line, manufacturers can improve efficiency, productivity, and overall profitability in the long run.

-768x512.jpg)