Table of Contents

فوائد استخدام شريط علبة الكيك لآلات الإغلاق

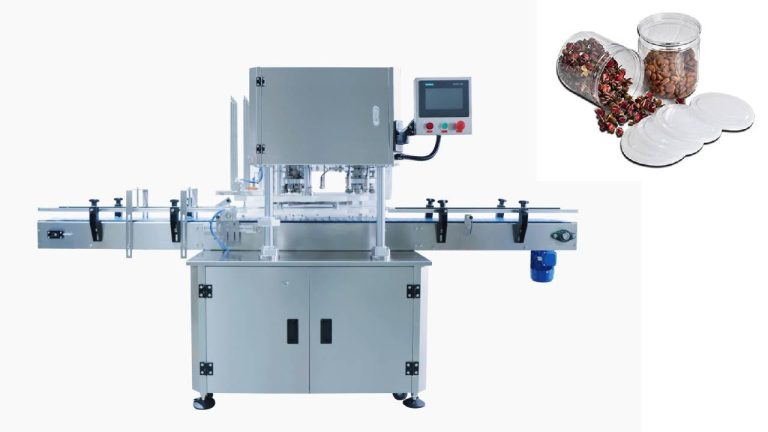

شريط علبة الكيك هو شريط لاصق متخصص يستخدم بشكل شائع في صناعة التعبئة والتغليف لإغلاق علب الكيك. ومع ذلك، يمكن أيضًا استخدام شريط علبة الكيك في تطبيقات أخرى، مثل آلات الإغلاق. تُستخدم آلات اللحام في صناعات مختلفة لربط قطعتين من المواد معًا، كما هو الحال في إنتاج العلب والحاويات والأشياء الأسطوانية الأخرى. باستخدام شريط علبة الكيك حول آلة الإغلاق، يمكن تحقيق العديد من الفوائد.

إحدى الفوائد الأساسية لاستخدام شريط علبة الكيك حول آلة الإغلاق هي قدرته على توفير ختم قوي وآمن. تضمن الخصائص اللاصقة لشريط علبة الكيك أن قطعتي المواد التي يتم ربطهما معًا يتم تثبيتهما بقوة في مكانهما، مما يمنع أي انزلاق أو حركة أثناء عملية التثبيت. يؤدي هذا إلى درز أكثر دقة ودقة، وهو أمر ضروري لضمان جودة المنتج النهائي وسلامته.

بالإضافة إلى توفير ختم قوي، يوفر شريط صندوق الكيك أيضًا مقاومة ممتازة للرطوبة والعوامل البيئية الأخرى. وهذا مهم بشكل خاص في الصناعات التي تتعرض فيها ماكينة اللحام لظروف قاسية، مثل الرطوبة العالية أو تقلبات درجات الحرارة. تساعد الخصائص المقاومة للرطوبة لشريط علبة الكيك على حماية الدرزة من أضرار المياه، مما يضمن بقاء المنتج النهائي سليمًا وآمنًا.

علاوة على ذلك، فإن شريط علبة الكيك متين للغاية ويدوم لفترة طويلة، مما يجعله خيارًا مثاليًا للاستخدام. على آلات الاغلاق. تم تصميم الشريط ليتحمل قسوة التطبيقات الصناعية، مثل خطوط الإنتاج عالية السرعة والآلات الثقيلة. تضمن خصائصه اللاصقة القوية بقاءه ثابتًا في مكانه، حتى في ظل الظروف الأكثر تطلبًا، مما يوفر ختمًا موثوقًا ومتسقًا في كل مرة.

من المزايا الأخرى لاستخدام شريط علبة الكيك حول آلة الإغلاق سهولة الاستخدام. يمكن تطبيق الشريط بسهولة على الماكينة دون الحاجة إلى أي أدوات أو معدات خاصة، مما يجعله حلاً مريحًا وفعالاً من حيث التكلفة لإغلاق اللحامات. بالإضافة إلى ذلك، يتوفر شريط علبة الكيك بمجموعة متنوعة من العروض والأطوال، مما يسمح بالتخصيص ليناسب المتطلبات المحددة لآلة الربط والمواد التي يتم ربطها معًا.

بشكل عام، يوفر استخدام شريط علبة الكيك حول ماكينة الربط العديد من المزايا المزايا، بما في ذلك الختم القوي والآمن، ومقاومة الرطوبة والعوامل البيئية، والمتانة، وسهولة الاستخدام. من خلال دمج شريط علبة الكيك في عملية الإغلاق، يمكن للمصنعين تحسين جودة وكفاءة خطوط الإنتاج الخاصة بهم، مما يؤدي إلى منتجات عالية الجودة وزيادة رضا العملاء.

في الختام، يعد شريط علبة الكيك حلاً متعدد الاستخدامات وفعالًا لإغلاق اللحامات على آلات الاغلاق. خصائصه اللاصقة ومتانته ومقاومته للرطوبة تجعله خيارًا مثاليًا لمجموعة واسعة من التطبيقات الصناعية. من خلال استخدام شريط علبة الكيك حول آلة الإغلاق، يمكن للمصنعين تحقيق ختم قوي وآمن، والحماية من العوامل البيئية، وتحسين الجودة والكفاءة الشاملة لعمليات الإنتاج الخاصة بهم.

كيفية وضع شريط علبة الكيك بشكل صحيح على آلات الربط

يعد شريط علبة الكيك مكونًا أساسيًا في عملية تعبئة الكعك والمخبوزات الأخرى. إنه يوفر ختمًا آمنًا لضمان بقاء محتويات الصندوق طازجة وسليمة أثناء النقل. يعد تطبيق شريط علبة الكيك بشكل صحيح على آلات الإغلاق أمرًا ضروريًا لتحقيق ختم قوي وموثوق. في هذه المقالة، سنناقش الخطوات المتضمنة في تطبيق شريط علبة الكيك على آلات الإغلاق لضمان عملية تغليف ناجحة.

أولاً وقبل كل شيء، من المهم تحديد النوع المناسب من شريط علبة الكيك لآلة الإغلاق الخاصة بك. هناك أنواع مختلفة من أشرطة علب الكيك المتوفرة في السوق، كل منها مصمم لتطبيقات محددة. من الضروري اختيار شريط متوافق مع آلة الإغلاق الخاصة بك لضمان التشغيل السلس والفعال. بالإضافة إلى ذلك، سيساعد اختيار شريط عالي الجودة على منع أي مشكلات مثل كسر الشريط أو ضعف الالتصاق.

بمجرد تحديد شريط علبة الكعك المناسب، فإن الخطوة التالية هي إعداد آلة التثبيت لتطبيق الشريط. تأكد من أن الجهاز نظيف وخالي من أي حطام قد يتداخل مع عملية وضع الشريط. بالإضافة إلى ذلك، تأكد من معايرة الماكينة بشكل صحيح لضمان وضع الشريط بشكل متساوٍ وآمن.

قبل وضع شريط علبة الكعك، من المهم قياس طول الشريط المطلوب لكل صندوق. سيساعد ذلك على منع الهدر والتأكد من تطبيق الشريط بدقة. بمجرد تحديد الطول الصحيح للشريط، قم بقصه حسب الحجم باستخدام شفرة حادة أو مقص.

لتطبيق شريط علبة الكيك على ماكينة الربط، ابدأ بوضع الصندوق على الحزام الناقل أو منصة الماكينة. ضع موزع الشريط فوق الصندوق، مع التأكد من محاذاة الشريط مع حواف الصندوق. اضغط على زر البدء الموجود على الجهاز لتنشيط موزع الشريط، مما يسمح بوضع الشريط بسلاسة وبشكل متساوٍ على طول طبقات الصندوق.

أثناء تطبيق الشريط، تأكد من مراقبة العملية للتأكد من ذلك يلتصق الشريط بشكل صحيح بالصندوق. إذا لاحظت أي مشكلات مثل انزلاق الشريط أو التطبيق غير المتساوي، فأوقف الجهاز على الفور وقم بإجراء التعديلات اللازمة. من المهم معالجة أي مشكلات على الفور لمنع أي فشل محتمل في التغليف.

بمجرد تطبيق الشريط، افحص الصندوق المغلق للتأكد من أن الشريط في مكانه بشكل آمن وأنه لا توجد فجوات أو تجاعيد في الختم. ستساعد الصناديق المغلقة بشكل صحيح على حماية المحتويات من العناصر الخارجية والحفاظ على نضارتها وجودتها. باتباع الخطوات الموضحة في هذه المقالة، يمكنك التأكد من وضع الشريط بشكل صحيح وآمن، مما يؤدي إلى ختم قوي وموثوق. تساعد الصناديق المغلقة بشكل صحيح على حماية المحتويات أثناء النقل والتخزين، مما يضمن وصول منتجاتك إلى وجهتها في حالة ممتازة.

المشكلات والحلول الشائعة عند استخدام شريط علبة الكيك على آلات الربط

يعد شريط علبة الكيك مادة شائعة تستخدم في صناعة التعبئة والتغليف لإغلاق الصناديق والتأكد من بقاء المحتويات آمنة أثناء النقل. عند استخدام شريط علبة الكيك على آلات الربط، هناك العديد من المشكلات الشائعة التي يمكن أن تنشأ. في هذه المقالة، سنناقش هذه المشكلات ونقدم حلولًا لمساعدتك في التغلب عليها.

أحد المشكلات الأكثر شيوعًا عند استخدام شريط علبة الكيك على آلات الربط هو كسر الشريط. يمكن أن يحدث هذا عندما لا يتم محاذاة الشريط بشكل صحيح مع بكرات الجهاز، مما يؤدي إلى تمزقه أو انكساره أثناء عملية الختم. لمنع انكسار الشريط، من المهم التأكد من تحميل الشريط بشكل صحيح على الجهاز ومحاذاة الأسطوانات بشكل صحيح. بالإضافة إلى ذلك، فإن استخدام شريط عالي الجودة مصمم للاستخدام مع آلات الربط يمكن أن يساعد في تقليل خطر الكسر.

هناك مشكلة شائعة أخرى عند استخدام شريط علبة الكيك على آلات الربط وهي انزلاق الشريط. يحدث هذا عندما لا يلتصق الشريط بشكل صحيح بالصندوق، مما يؤدي إلى انزلاقه أو تفككه أثناء عملية الختم. لمنع انزلاق الشريط، من المهم التأكد من أن سطح الصندوق نظيف وخالي من أي غبار أو حطام قد يتداخل مع التصاق الشريط. بالإضافة إلى ذلك، يمكن أن يساعد ضبط إعدادات الجهاز لتطبيق المزيد من الضغط على الشريط في ضمان الختم الآمن.

في بعض الحالات، يمكن أن يحدث تشويش للشريط عند استخدام شريط علبة الكيك على آلات اللحام. يحدث هذا عندما يعلق الشريط في بكرات الماكينة أو المكونات الأخرى، مما يمنعه من التحرك بسلاسة خلال عملية الختم. لحل مشكلات تشويش الشريط، من المهم تنظيف الجهاز وصيانته بانتظام لمنع تراكم بقايا الشريط أو الحطام. بالإضافة إلى ذلك، يمكن أن يساعد التحقق من شد الشريط ومحاذاته في منع حدوث انحشارات.

إحدى أكثر المشكلات المحبطة عند استخدام شريط علبة الكيك على آلات الربط هي الختم غير المتساوي. يمكن أن يحدث هذا عندما لا يتم تطبيق الشريط بالتساوي على الصندوق، مما يؤدي إلى وجود فجوات أو نقاط ضعف في الختم. لتحقيق ختم موحد، من المهم التأكد من تحميل الشريط على الماكينة بشكل مستقيم وضبط التوتر بشكل صحيح. بالإضافة إلى ذلك، فإن استخدام شريط أوسع أو ضبط إعدادات الجهاز لتطبيق المزيد من الضغط يمكن أن يساعد في إنشاء ختم أكثر اتساقًا.

بشكل عام، يمكن أن يكون استخدام شريط علبة الكيك على آلات الإغلاق طريقة مريحة وفعالة لإغلاق الصناديق للشحن أو التخزين. من خلال إدراك المشكلات الشائعة مثل كسر الشريط، والانزلاق، والتشويش، والختم غير المتساوي، يمكنك اتخاذ خطوات لمنع حدوث هذه المشكلات. باتباع الحلول المقدمة في هذه المقالة، يمكنك التأكد من وضع شريط علبة الكيك الخاص بك بسلاسة وأمان، مما يساعد على حماية منتجاتك أثناء النقل.