Table of Contents

Benefits of Using a Can Seaming Machine for Liquid Beer Cans

When it comes to packaging liquid products like beer, having a reliable and efficient can seaming machine is essential. These machines are designed to seal cans securely, ensuring that the contents remain fresh and free from contamination. In this article, we will explore the benefits of using a can seaming machine for liquid beer cans.

One of the primary advantages of using a can seaming machine is the consistency and precision it offers. These machines are designed to seal cans with the same level of accuracy every time, ensuring that each can is properly sealed and airtight. This consistency is crucial for maintaining the quality of the beer and preventing any leaks or spoilage.

In addition to consistency, can seaming machines also offer speed and efficiency. These machines are capable of sealing hundreds of cans per minute, significantly increasing production rates and reducing labor costs. This allows breweries to meet high demand and maximize their output without sacrificing quality.

Another benefit of using a can seaming machine is the reduction of waste. Manual sealing methods can often result in errors and imperfect seals, leading to wasted product and resources. Can seaming machines eliminate these issues by providing a reliable and secure seal every time, minimizing the risk of spoilage and ensuring that every can is properly sealed.

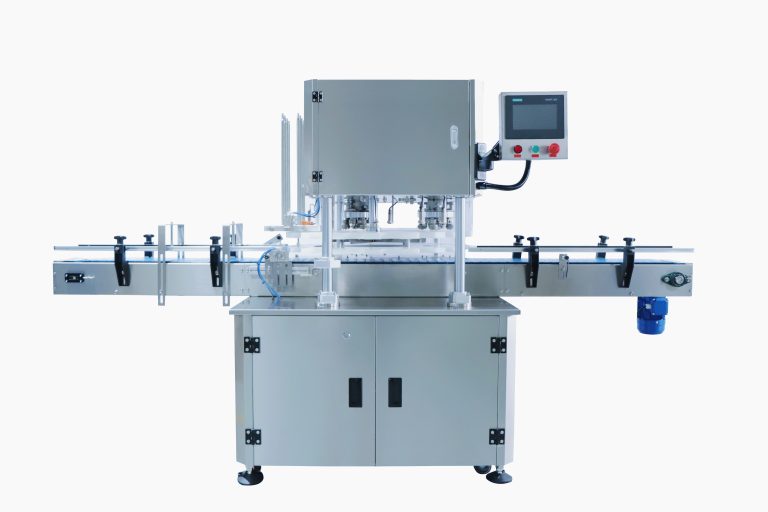

Furthermore, can seaming machines are designed to be easy to use and maintain. With user-friendly interfaces and simple operation, these machines can be operated by a single person with minimal training. Additionally, regular maintenance and cleaning are straightforward, ensuring that the machine remains in optimal condition and continues to perform efficiently.

In terms of safety, can seaming machines offer several advantages. These machines are equipped with safety features such as emergency stop buttons and protective guards to prevent accidents and injuries. By automating the sealing process, can seaming machines also reduce the risk of repetitive strain injuries associated with manual sealing methods.

From a financial perspective, investing in a can seaming machine can result in long-term cost savings. While the initial investment may be significant, the efficiency and productivity gains provided by these machines can quickly offset the upfront costs. Additionally, the reduction in waste and spoilage can lead to further savings over time.

In conclusion, using a can seaming machine for liquid beer cans offers a wide range of benefits, including consistency, speed, efficiency, waste reduction, ease of use, safety, and cost savings. By investing in a high-quality can seaming machine, breweries can improve their production processes, increase output, and maintain the quality of their products. Overall, a can seaming machine is an essential tool for any brewery looking to streamline their packaging operations and deliver a superior product to consumers.

How to Choose the Right Can Seaming Machine for Your Brewery

When it comes to packaging liquid beer in cans, having the right can seaming machine is crucial for ensuring a tight seal and maintaining the quality of the product. With so many options available on the market, choosing the right can seaming machine for your brewery can be a daunting task. In this article, we will discuss some key factors to consider when selecting a can seaming machine for your brewery.

One of the first things to consider when choosing a can seaming machine is the size and speed of your production line. Different can seaming machines are designed to handle different volumes of cans per minute, so it is important to choose a machine that can keep up with the demands of your brewery. Additionally, consider the size of the cans you will be using, as some machines are designed to handle specific can sizes.

Another important factor to consider is the type of seaming process that the machine uses. There are two main types of seaming processes used in can seaming machines: rotary seaming and reciprocating seaming. Rotary seaming machines are typically faster and more efficient, making them ideal for high-volume production lines. Reciprocating seaming machines, on the other hand, are better suited for smaller breweries with lower production volumes.

In addition to the seaming process, it is important to consider the quality of the seals produced by the can seaming machine. A tight seal is essential for preventing leaks and maintaining the freshness of the beer. Look for a machine that is capable of producing consistent and reliable seals, as this will help to minimize product waste and ensure customer satisfaction.

When choosing a can seaming machine, it is also important to consider the overall build quality and durability of the machine. Look for a machine that is made from high-quality materials and is built to last. A well-built machine will require less maintenance and repairs, saving you time and money in the long run.

Finally, consider the level of automation and control offered by the can seaming machine. Some machines come with advanced features such as touchscreen controls, automatic lid feeders, and real-time monitoring systems. These features can help to streamline your production process and improve efficiency.

In conclusion, choosing the right can seaming machine for your brewery is a critical decision that can have a significant impact on the quality and efficiency of your production line. Consider factors such as production volume, seaming process, seal quality, build quality, and automation when selecting a machine. By taking the time to research and evaluate your options, you can find a can seaming machine that meets the needs of your brewery and helps you to produce high-quality beer in cans.