Automatic Single Head ROPP Capping Machine With Cap Feeder

Automatic Single Head ROPP Capping machine can work with wide shaped of container like Round, Square with minimum change part. The machine speed and application depend of bottle like Glass, Plastic, PET, Aluminum Bottles etc with maximum speed of 2000 Bottles per hour depending on Bottle Diameter, Bottle Height, Bottle Shape and Cap Size customer use for pharmaceutical, Liquor, wine , honey , syrup , cosmetic, chemical, food and other industry.

Equipment principle:

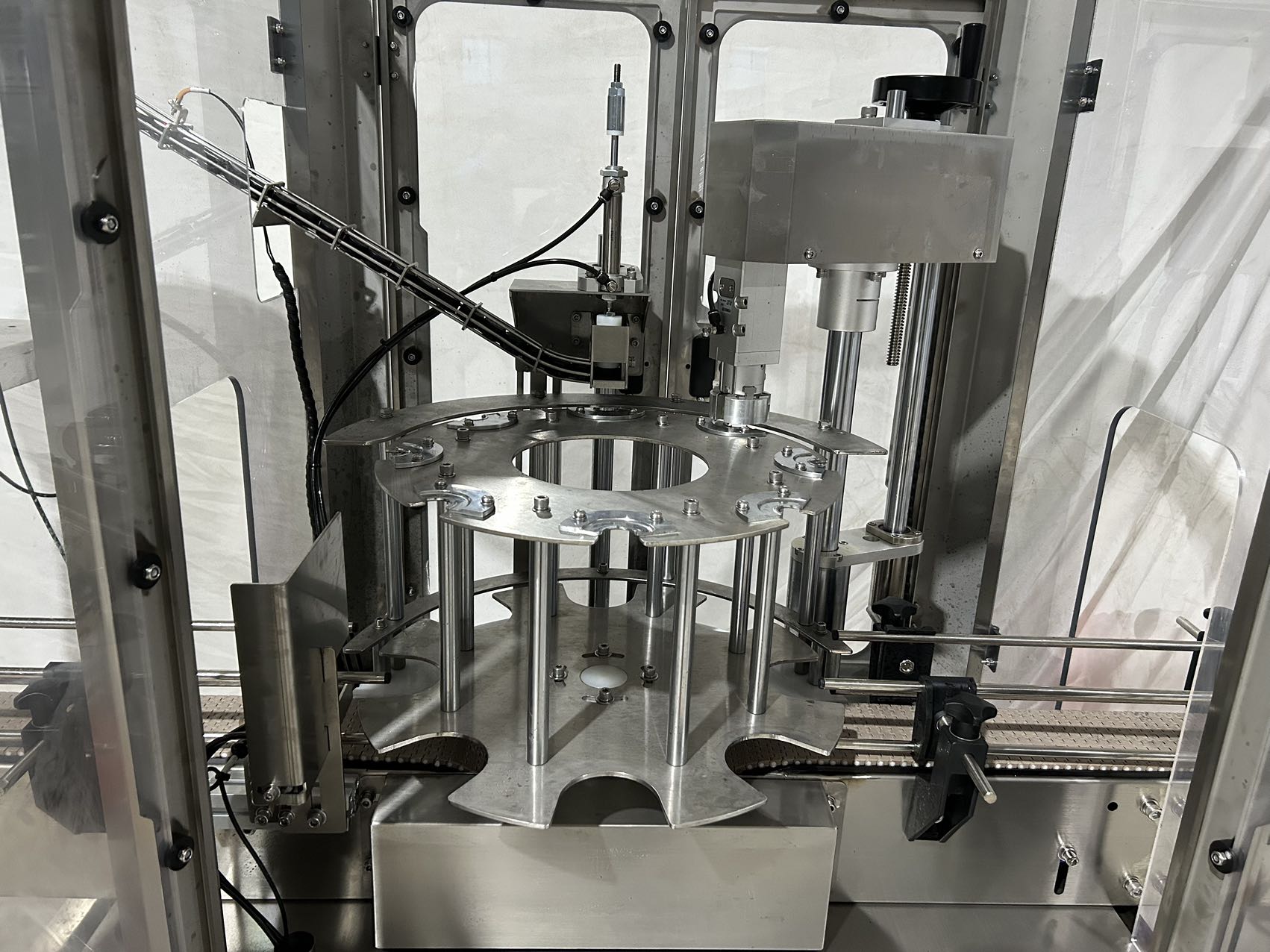

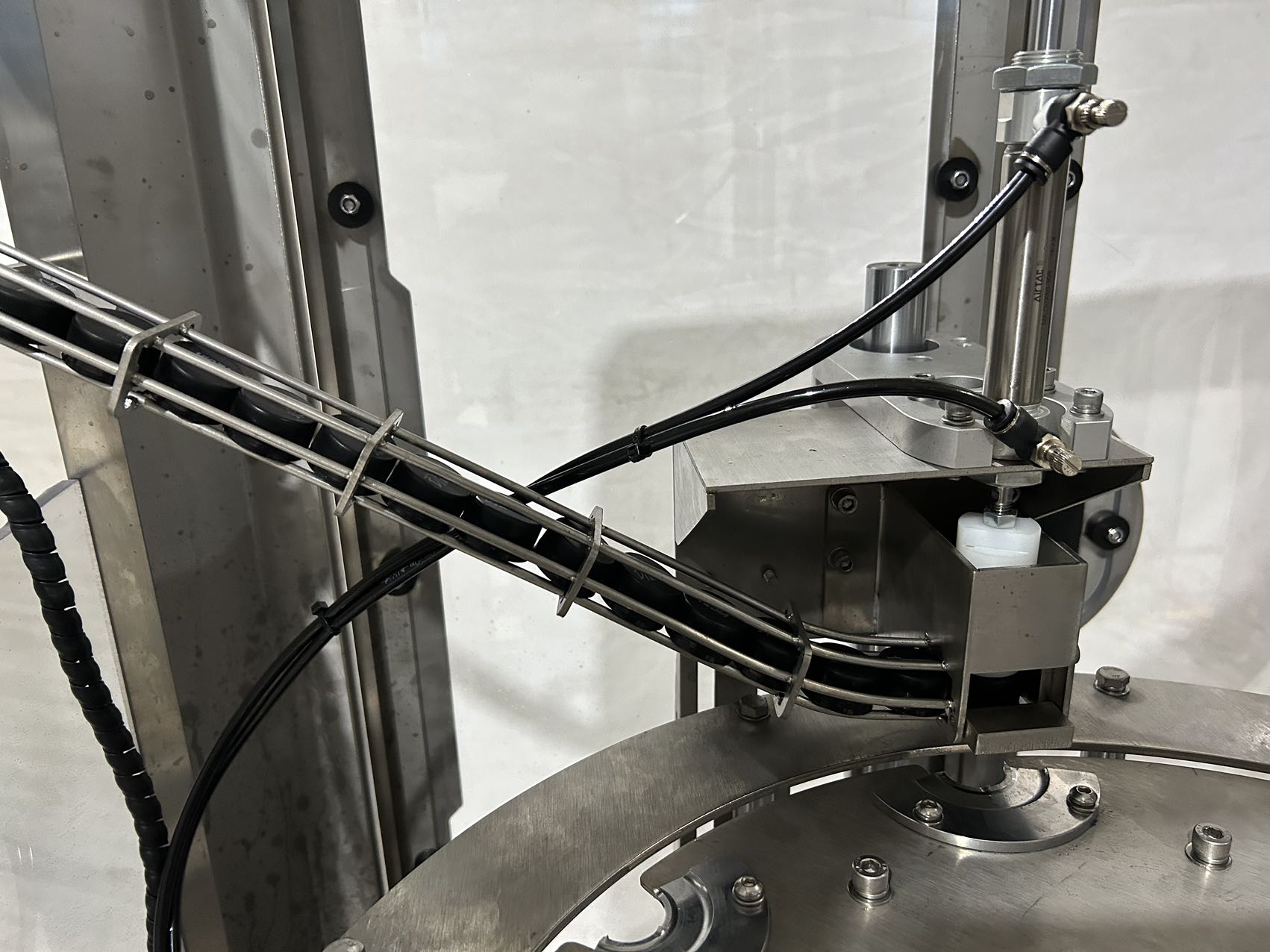

The main components of the equipment are composed of a vibration plate, a lid track, a turntable, and a capping head; the main function of the vibration plate is to arrange the lids into a uniform posture and then output them to the lid track to reach the capping station; the cans are positioned and intermittently conveyed by the turntable, and a three-hook anti-rotation knife is installed on the turntable. The anti-rotation knife is made of hard mold steel. When the cap is screwed, the cap is clamped by the capping head and rotated clockwise to generate downward pressure. The three hooks of the anti-rotation knife clamp the bottleneck to reduce or avoid the rotation of the bottle to complete the capping action;

Main features:

1. The turntable uses a stopper rod to fix the bottle body, and the machine head follows the cam mechanical transmission to rise and fall. The principle is simple, the adjustment is convenient, and the force is balanced;

2. The servo claw capping is adopted. The torque and speed can be set on the screen during the capping process. It is reliable and safe, especially suitable for screw cap packaging;

3. The stopper rod is made of high-speed steel, which is sturdy and durable; the part of the capping head that contacts the bottle cap is made of polyurethane, which is wear-resistant and does not damage the bottle cap;

4. It adopts Siemens PLC and Siemens touch screen human-machine interface, which is extremely simple and clear to use;

5. Automatic detection of bottle caps, insufficient cap alarm, circuit The control design is reasonable, safe and reliable;

Main Parameters:

1. Power supply (220V 60Hz 3 phase) & air source (0.6-0.8Mpa)

2. Capping head: 1 head (including vibration plate automatic capping)

4. Capping speed: 1200-2000 bottles/hour

5. Capping bottle diameter: 20-50mm (customizable)

6. Bottle diameter: 20-120mm (customizable)

7. Bottle height: 30-250mm (customizable)

8. Power: 1.5KW

9. Dimensions: 1800mm Lx 900mm Wx 1600mm H