Table of Contents

The Advantages of Using a Semi Automatic Can Sealer for Small-Scale Production

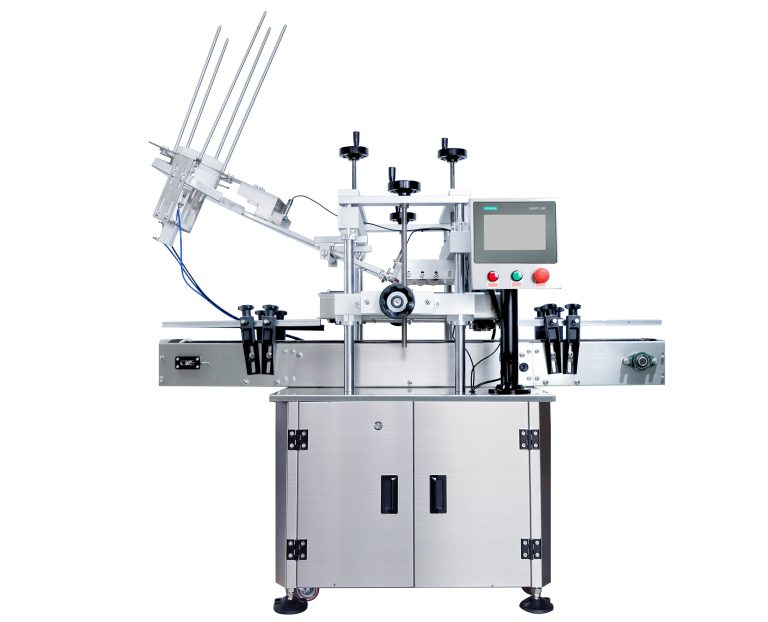

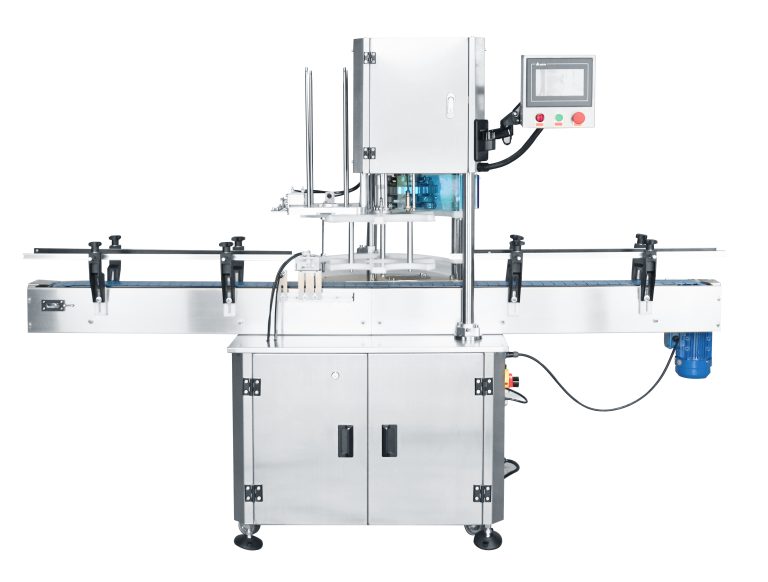

In the world of small-scale production, efficiency and precision are key factors in ensuring the success of a business. One tool that has become indispensable for many small-scale producers is the semi-automatic can sealer. This innovative piece of equipment merges precision and ingenuity to streamline the can sealing process, making it easier and more efficient for producers to package their products.

One of the main advantages of using a semi-automatic can sealer is its ability to seal cans quickly and accurately. Unlike manual can sealing methods, which can be time-consuming and prone to human error, a semi-automatic can sealer automates the sealing process, ensuring that each can is sealed with precision and consistency. This not only saves time and labor costs but also helps to maintain the quality and integrity of the product being packaged.

Another advantage of using a semi-automatic can sealer is its versatility. These machines are designed to seal a wide range of can sizes and types, making them suitable for a variety of products, from food and beverages to cosmetics and pharmaceuticals. This flexibility allows small-scale producers to package their products in a professional and efficient manner, regardless of the size or type of cans they are using.

In addition to their speed and versatility, semi-automatic can sealers are also easy to operate and maintain. Most models come with user-friendly controls and settings, making it simple for operators to adjust the machine to suit their specific needs. Furthermore, these machines are built to last, with durable construction and high-quality components that require minimal maintenance. This means that small-scale producers can rely on their semi-automatic can sealer to perform consistently and reliably, without the need for frequent repairs or replacements.

One of the key benefits of using a semi-automatic can sealer is its cost-effectiveness. While the initial investment in a semi-automatic can sealer may be higher than manual sealing methods, the long-term savings in labor costs and increased productivity make it a worthwhile investment for small-scale producers. By automating the can sealing process, producers can increase their output and efficiency, ultimately leading to higher profits and a more competitive edge in the market.

Overall, the advantages of using a semi-automatic can sealer for small-scale production are clear. From its speed and precision to its versatility and cost-effectiveness, this innovative piece of equipment offers small-scale producers a reliable and efficient solution for packaging their products. By investing in a semi-automatic can sealer, producers can streamline their production process, improve the quality of their products, and ultimately grow their business in a competitive market.

How Semi Automatic Can Sealers Combine Precision Engineering with Innovative Technology

In the world of food and beverage packaging, precision and efficiency are key factors in ensuring product quality and consumer satisfaction. One technology that has revolutionized the canning process is the semi-automatic can sealer. These machines combine precision engineering with innovative technology to streamline the sealing process and produce airtight seals on cans of various sizes and materials.

Semi-automatic can sealers are designed to seal cans quickly and accurately, reducing the risk of contamination and spoilage. These machines are equipped with advanced sensors and controls that monitor the sealing process in real-time, ensuring that each can is sealed to perfection. The precision engineering behind these machines allows for consistent and reliable sealing, regardless of the volume of cans being processed.

One of the key features of semi-automatic can sealers is their versatility. These machines can seal cans of different sizes and materials, making them ideal for a wide range of food and beverage products. Whether you are packaging canned fruits, vegetables, or beverages, a semi-automatic can sealer can handle the job with ease. This versatility is made possible by the innovative technology integrated into these machines, which allows for quick and easy adjustments to accommodate different can sizes and materials.

Another advantage of semi-automatic can sealers is their efficiency. These machines are designed to seal cans at a high speed, reducing production time and increasing output. The precision engineering of these machines ensures that each can is sealed quickly and accurately, minimizing the risk of leaks or spoilage. This efficiency is further enhanced by the user-friendly interface of semi-automatic can sealers, which allows operators to easily control and monitor the sealing process.

In addition to their precision and efficiency, semi-automatic can sealers are also known for their durability and reliability. These machines are built to withstand the rigors of continuous use in a production environment, ensuring long-lasting performance and minimal downtime. The innovative technology integrated into these machines allows for easy maintenance and troubleshooting, further enhancing their reliability.

Overall, semi-automatic can sealers are a testament to the merging of precision engineering and innovative technology in the packaging industry. These machines offer a perfect balance of accuracy, efficiency, versatility, and reliability, making them an essential tool for food and beverage manufacturers looking to streamline their canning process. With their advanced sensors, controls, and user-friendly interface, semi-automatic can sealers are able to produce airtight seals on cans of various sizes and materials with ease. Whether you are packaging canned fruits, vegetables, or beverages, a semi-automatic can sealer can help you achieve consistent and reliable sealing results, ensuring the quality and safety of your products.