فوائد استخدام آلة إغلاق علب الألمنيوم بالماء الصودا

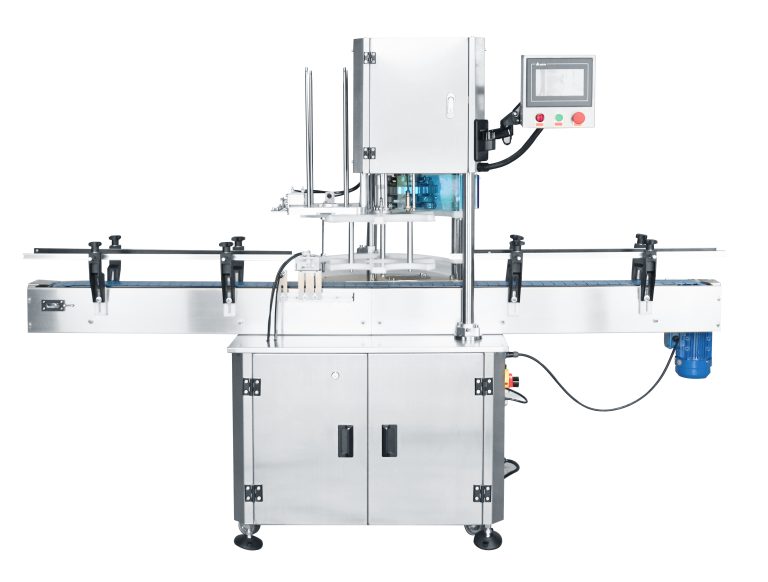

تعد آلات إغلاق علب الألمنيوم بالمياه الغازية من المعدات الأساسية لمصنعي المشروبات الذين يتطلعون إلى إغلاق علب الألمنيوم المملوءة بالمياه الغازية بكفاءة. توفر هذه الآلات مجموعة من المزايا التي يمكن أن تساعد في تبسيط عمليات الإنتاج وتحسين الكفاءة العامة. في هذه المقالة، سوف نستكشف بعض المزايا الرئيسية لاستخدام آلة إغلاق علب الألومنيوم بالماء الصودا.

إحدى الفوائد الأساسية لاستخدام آلة إغلاق علب الألومنيوم بالمياه الغازية هي قدرتها على توفير ختم ثابت وموثوق على الألومنيوم. علب. تم تصميم هذه الآلات لإغلاق العلب بدقة باستخدام وصلة محكمة وآمنة، مما يضمن بقاء المحتويات طازجة ومكربنة لفترة طويلة. يعد هذا المستوى من الاتساق أمرًا بالغ الأهمية للحفاظ على جودة المنتج وتلبية توقعات المستهلك.

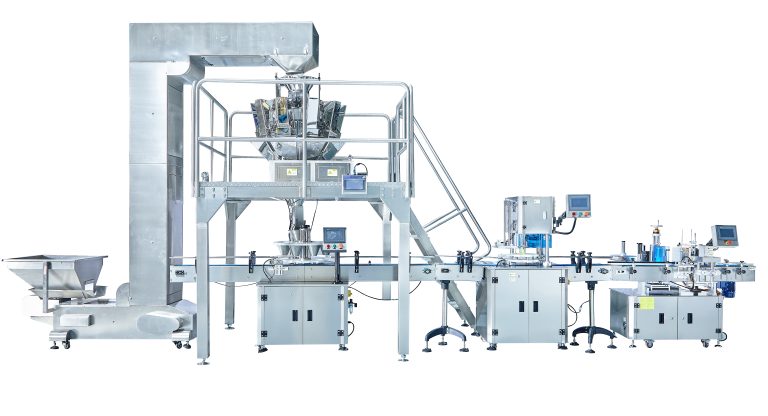

بالإضافة إلى ضمان الختم الموثوق به، فإن آلات إغلاق علب الألومنيوم بالمياه الغازية توفر أيضًا سرعات إنتاج متزايدة. هذه الآلات قادرة على إغلاق عدد كبير من العلب في فترة زمنية قصيرة، مما يسمح للمصنعين بتلبية الطلب المرتفع وزيادة إنتاج الإنتاج إلى أقصى حد. يمكن أن تساعد هذه الكفاءة المتزايدة في تقليل تكاليف الإنتاج وتحسين الربحية الإجمالية.

علاوة على ذلك، تم تصميم آلات إغلاق علب الألومنيوم بالمياه الغازية لتكون سهلة الاستخدام وسهلة التشغيل. بفضل عناصر التحكم البديهية وإجراءات الإعداد البسيطة، يمكن للمشغلين أن يتعلموا بسرعة كيفية استخدام هذه الآلات بفعالية، مما يقلل الحاجة إلى تدريب مكثف ويقلل من مخاطر الأخطاء. يمكن أن تساعد سهولة الاستخدام هذه في تحسين الإنتاجية الإجمالية وتقليل وقت التوقف عن العمل. هذه الآلات قادرة على إغلاق العلب بمختلف الأحجام والأشكال، مما يجعلها مناسبة لمجموعة واسعة من منتجات المشروبات. سواء كنت تقوم بتعبئة المياه الغازية التقليدية أو تجرب نكهات وتركيبات جديدة، يمكن لآلة إغلاق علب ألومنيوم المياه الغازية أن تلبي احتياجاتك.

بالإضافة إلى ذلك، تم تصميم آلات إغلاق علب ألومنيوم المياه الغازية لتكون متينة وطويلة الأمد. تم تصنيع هذه الآلات من مواد عالية الجودة لتتحمل قسوة الاستخدام المستمر في بيئة الإنتاج. تساعد هذه المتانة على تقليل متطلبات الصيانة وتضمن بقاء الماكينة جاهزة للعمل لسنوات قادمة.

بشكل عام، فوائد استخدام ماكينة إغلاق علب الألمنيوم بالماء الصودا واضحة. بدءًا من توفير ختم ثابت وزيادة سرعات الإنتاج وحتى توفير التنوع والمتانة، توفر هذه الآلات مجموعة من المزايا التي يمكن أن تساعد مصنعي المشروبات على تحسين الكفاءة والحفاظ على جودة المنتج. من خلال الاستثمار في آلة إغلاق علب الألمنيوم بالماء الصودا، يمكن للمصنعين تبسيط عمليات الإنتاج الخاصة بهم، وخفض التكاليف، وفي نهاية المطاف تعزيز قدرتهم التنافسية في السوق.