Table of Contents

Exploring the Efficiency of Automatic Can Sealing Machines

The advent of technology has revolutionized various sectors, including the packaging industry. One of the most significant innovations in this field is the automatic can sealing machine, a product of advanced engineering from can closing machine factories. This machine has transformed the packaging process, making it more efficient, reliable, and cost-effective.

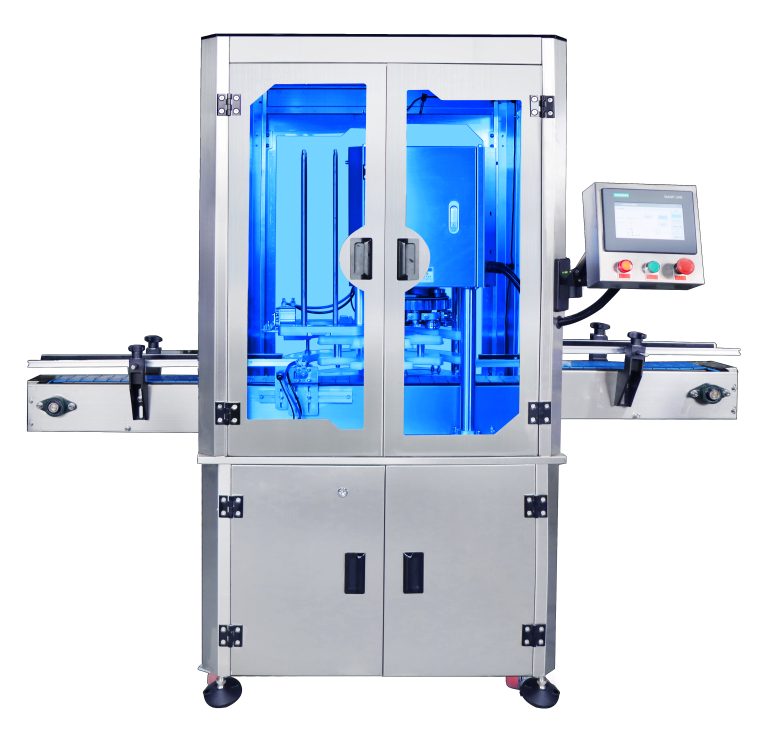

Automatic can sealing machines are designed to seal cans of different sizes and shapes automatically. They are equipped with advanced features that allow them to operate at high speeds, thus increasing productivity. The machines are also designed to ensure precision in the sealing process, which significantly reduces the chances of product contamination.

The efficiency of automatic can sealing machines is primarily attributed to their high-speed operation. These machines can seal hundreds, if not thousands, of cans per hour, depending on their model and configuration. This high-speed operation is a significant advantage, especially for large-scale manufacturers who need to package vast quantities of products within a short period.

Moreover, automatic can sealing machines are designed with precision in mind. They are equipped with advanced sensors and control systems that ensure each can is sealed correctly. This precision not only guarantees the quality of the seal but also minimizes wastage that could result from poorly sealed cans.

Another notable feature of automatic can sealing machines is their versatility. These machines can handle cans of different sizes and shapes, making them suitable for various applications. Whether you need to seal small, medium, or large cans, you can rely on an automatic can sealing machine to get the job done efficiently.

The durability of these machines is another factor that contributes to their efficiency. Automatic can sealing machines are typically made from high-quality materials that can withstand the rigors of industrial use. This durability ensures that the machines can operate for extended periods without breaking down, thus minimizing downtime and maximizing productivity.

In addition to their operational efficiency, automatic can sealing machines also offer economic benefits. By automating the can sealing process, these machines significantly reduce the need for manual labor, thus lowering labor costs. Furthermore, their high-speed operation and precision reduce wastage, which translates to cost savings in the long run.

The automatic can sealing machines are a product of continuous research and development by can closing machine factories. These factories are committed to improving the efficiency and reliability of their machines to meet the ever-changing needs of the packaging industry. They invest heavily in technology and innovation to develop machines that offer superior performance and value for money.

In conclusion, automatic can sealing machines have revolutionized the packaging process by offering a more efficient and reliable solution for sealing cans. Their high-speed operation, precision, versatility, and durability make them an invaluable asset for any manufacturer. Moreover, their economic benefits make them a cost-effective solution for the packaging industry. As technology continues to advance, we can expect even more improvements in the efficiency and reliability of these machines, further enhancing their value in the packaging industry.

Inside the Production: A Look at Can Closing Machine Factories

The world of manufacturing is a fascinating one, filled with intricate machinery and complex processes. One such marvel of modern engineering is the automatic can sealing machine, also known as the can closing machine. These machines are integral to the packaging industry, playing a crucial role in ensuring that canned goods are sealed properly to maintain their freshness and quality.

The automatic can sealing machine is a testament to the ingenuity and innovation of the manufacturing industry. It is designed to seal cans of various sizes and shapes, from small tuna cans to large paint cans. The machine operates by first placing the lid onto the can, then applying pressure to create a tight seal. This process is carried out at high speeds, allowing for the efficient packaging of thousands of cans per hour.

The production of these machines takes place in specialized factories, where precision and quality control are of utmost importance. The process begins with the design phase, where engineers draft blueprints and create 3D models of the machine. This stage is crucial as it lays the foundation for the entire manufacturing process.

Once the design is finalized, the production phase begins. This involves the fabrication of the machine parts, which are typically made from durable materials such as stainless steel or aluminum. These parts are then assembled to form the complete machine. The assembly process requires a high level of precision to ensure that all components fit together perfectly and function as intended.

After the machine is assembled, it undergoes rigorous testing to ensure it meets the required standards. This includes checking the machine’s sealing capability, speed, and overall performance. Any defects or issues identified during this stage are rectified before the machine is approved for distribution.

The final stage in the production process is packaging and shipping. The machines are carefully packed to prevent any damage during transit and are then shipped to customers around the world.

The production of automatic can sealing machines is a complex process that requires a high level of expertise and precision. However, the result is a machine that plays a vital role in the packaging industry, ensuring that canned goods are sealed properly to maintain their freshness and quality.

The factories that produce these machines are constantly innovating and improving their processes to increase efficiency and quality. They invest heavily in research and development to create machines that are more reliable, faster, and more efficient. This constant drive for improvement is what keeps these factories at the forefront of the manufacturing industry.

In conclusion, the automatic can sealing machine is a marvel of modern engineering, playing a crucial role in the packaging industry. The production of these machines is a complex process that takes place in specialized factories, where precision and quality control are of utmost importance. These factories are constantly innovating and improving their processes, ensuring that they continue to produce machines of the highest quality.