Table of Contents

Benefits of Investing in High-Quality Can Sealing Machinery

When it comes to packaging products in cans, choosing the right can sealing machinery is crucial for ensuring the quality and safety of your products. Investing in high-quality can sealing machinery can offer a wide range of benefits for your packaging needs. From increased efficiency and productivity to improved product quality and reduced downtime, the right can sealing machinery can make a significant impact on your packaging operations.

One of the key benefits of investing in high-quality can sealing machinery is increased efficiency. High-quality can sealing machinery is designed to operate at optimal speeds, allowing you to seal a large number of cans quickly and efficiently. This can help you meet production deadlines and keep up with customer demand, ultimately improving your overall productivity.

In addition to increased efficiency, high-quality can sealing machinery can also improve the quality of your products. By ensuring a tight and secure seal on each can, you can prevent leaks and contamination, preserving the freshness and integrity of your products. This can help you maintain a positive reputation with customers and reduce the risk of costly product recalls.

Another benefit of investing in high-quality can sealing machinery is reduced downtime. High-quality machinery is built to last, with durable components that can withstand the rigors of continuous use. This can help minimize the need for repairs and maintenance, keeping your production line running smoothly and reducing the risk of costly downtime.

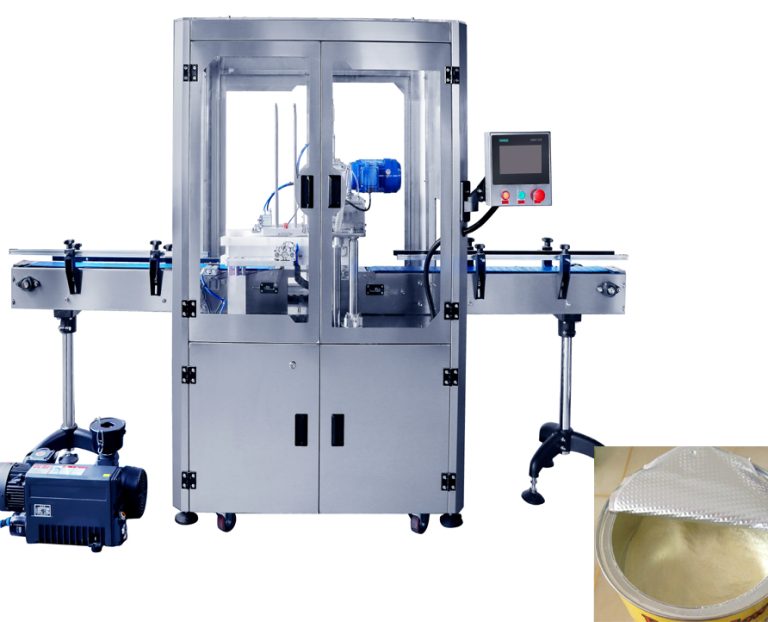

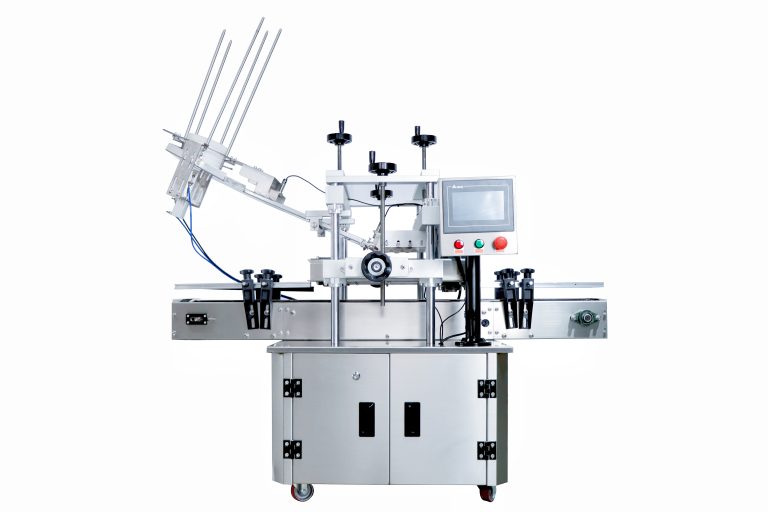

Furthermore, high-quality can sealing machinery is often equipped with advanced features and technology that can further enhance your packaging operations. From automatic lid feeders and seam inspection systems to touch screen controls and remote monitoring capabilities, these features can help streamline your packaging process and improve overall efficiency.

When choosing the right can sealing machinery for your packaging needs, it’s important to consider factors such as the size and type of cans you will be sealing, as well as your production volume and budget. There are a wide range of can sealing machinery options available, from manual tabletop sealers to fully automated production lines, so it’s important to carefully evaluate your specific requirements before making a decision.

In conclusion, investing in high-quality can sealing machinery can offer a wide range of benefits for your packaging operations. From increased efficiency and productivity to improved product quality and reduced downtime, the right can sealing machinery can help you streamline your packaging process and enhance the overall quality of your products. By carefully evaluating your requirements and choosing the right machinery for your needs, you can ensure that your packaging operations run smoothly and efficiently, ultimately helping you achieve success in the competitive marketplace.

Factors to Consider When Selecting Can Sealing Machinery for Different Packaging Requirements

When it comes to packaging products in cans, choosing the right can sealing machinery is crucial to ensure that your products are properly sealed and protected. There are several factors to consider when selecting can sealing machinery for different packaging requirements. From the type of product being packaged to the production volume and budget constraints, each factor plays a key role in determining the most suitable can sealing machinery for your needs.

One of the first factors to consider when selecting can sealing machinery is the type of product being packaged. Different products require different sealing methods to ensure that they are properly sealed and protected. For example, liquid products may require a different sealing method than dry products, as liquids can be more prone to leakage if not properly sealed. Additionally, products that are sensitive to oxygen or moisture may require a more airtight seal to ensure their freshness and quality.

Another important factor to consider when selecting can sealing machinery is the production volume. The production volume will determine the size and capacity of the can sealing machinery needed to meet your packaging requirements. For small-scale production, a manual or semi-automatic can sealing machine may be sufficient, while larger production volumes may require a fully automatic can sealing machine to meet the demand.

Budget constraints are also an important factor to consider when selecting can sealing machinery. The cost of can sealing machinery can vary depending on the type and capacity of the machine, as well as any additional features or customization options. It is important to consider your budget constraints and weigh them against the features and capabilities of the can sealing machinery to ensure that you are getting the best value for your investment.

In addition to the type of product, production volume, and budget constraints, there are several other factors to consider when selecting can sealing machinery. These factors include the size and shape of the cans being used, the speed and efficiency of the machine, and any additional features or customization options that may be required for your specific packaging needs.

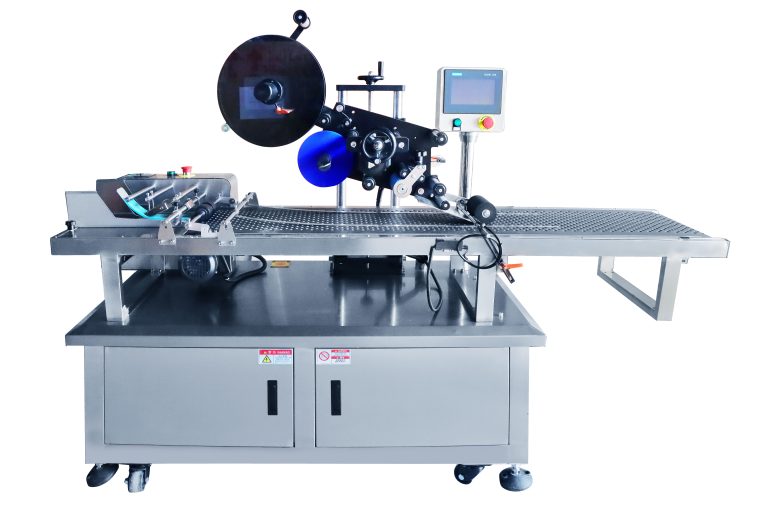

The size and shape of the cans being used will determine the type of can sealing machinery needed to properly seal the cans. Some can sealing machines are designed for specific can sizes and shapes, while others may be more versatile and able to accommodate a variety of can sizes and shapes. It is important to consider the size and shape of the cans being used to ensure that the can sealing machinery is compatible with your packaging requirements.

The speed and efficiency of the can sealing machinery are also important factors to consider when selecting a machine for your packaging needs. The speed of the machine will determine how quickly and efficiently it can seal the cans, which can impact production output and overall efficiency. It is important to consider the speed and efficiency of the can sealing machinery to ensure that it can meet your production requirements and deadlines.

Finally, any additional features or customization options that may be required for your specific packaging needs should also be considered when selecting can sealing machinery. Some can sealing machines may offer additional features such as date coding, labeling, or tamper-evident seals, which can be important for certain products or industries. It is important to consider any additional features or customization options that may be required for your packaging needs to ensure that the can sealing machinery meets all of your requirements.

In conclusion, choosing the right can sealing machinery for your packaging needs is a critical decision that can impact the quality, efficiency, and cost-effectiveness of your packaging operations. By considering factors such as the type of product, production volume, budget constraints, size and shape of the cans, speed and efficiency of the machine, and any additional features or customization options, you can select the most suitable can sealing machinery for your specific packaging requirements.