Key Factors to Consider When Choosing a Tin Can Sealer Machine

When it comes to choosing the right tin can sealer machine for your production, there are several key factors that you need to consider. The type of tin can sealer machine you choose will depend on the size of your production, the type of cans you are sealing, and your budget. In this article, we will discuss some of the key factors that you should keep in mind when selecting a tin can sealer machine for your production.

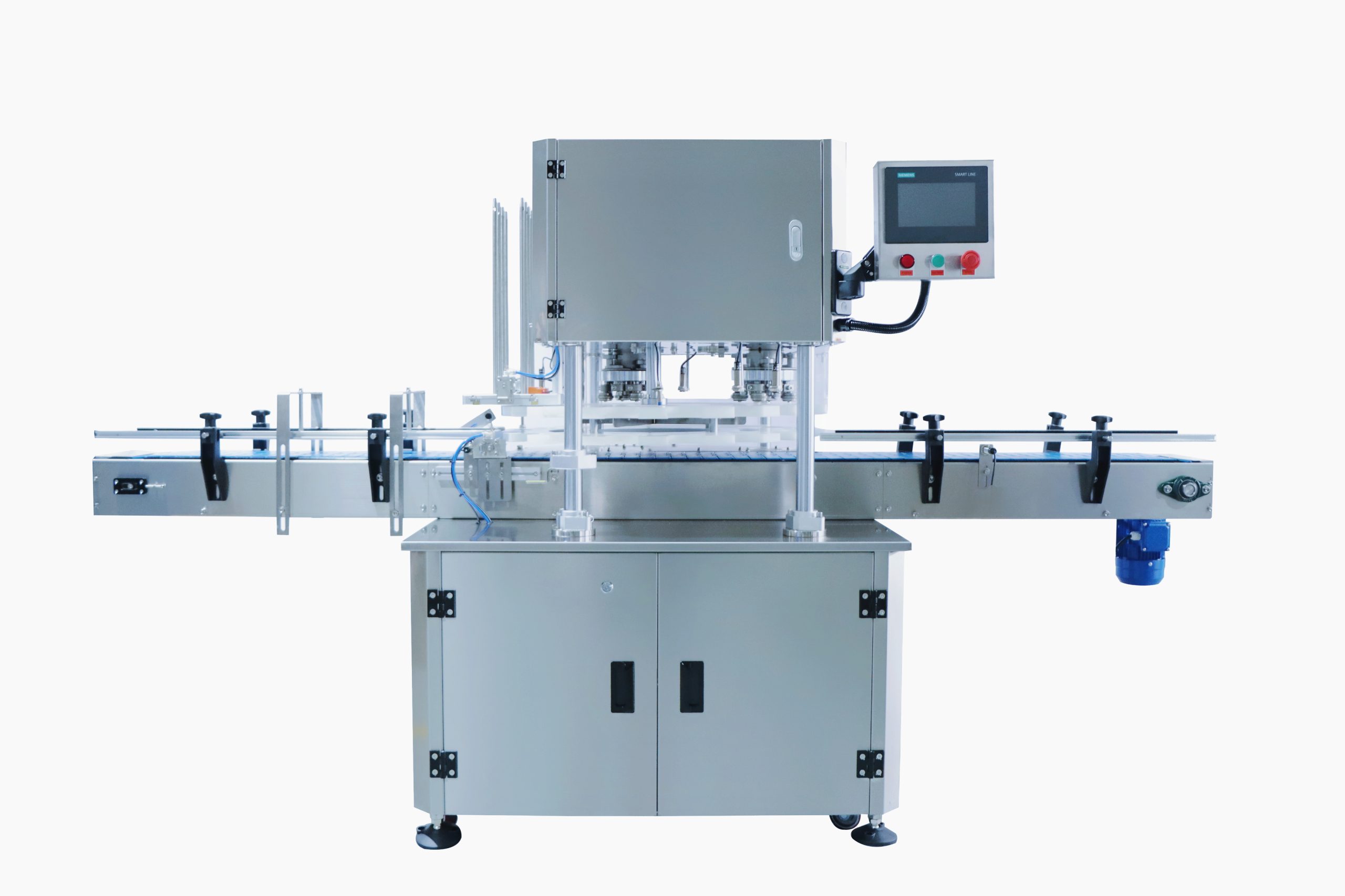

One of the most important factors to consider when choosing a tin can sealer machine is the size of your production. If you have a small production volume, you may be able to get by with a manual or semi-automatic tin can sealer machine. These machines are typically less expensive than fully automatic machines and are well-suited for smaller production runs. However, if you have a larger production volume, you may need to invest in a fully automatic tin can sealer machine to keep up with demand.

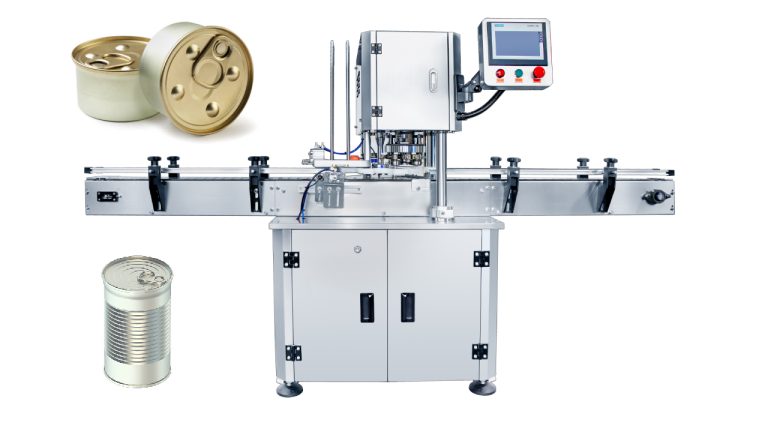

Another important factor to consider when choosing a tin can sealer machine is the type of cans you are sealing. Tin can sealer machines come in a variety of sizes and configurations to accommodate different types of cans, including round cans, square cans, and rectangular cans. You will need to choose a machine that is compatible with the size and shape of the cans you are using in your production.

In addition to the size and shape of the cans, you will also need to consider the material of the cans when choosing a tin can sealer machine. Some machines are designed specifically for sealing metal cans, while others are designed for sealing plastic or composite cans. Make sure to choose a machine that is compatible with the material of the cans you are using in your production to ensure a proper seal.

Cost is another important factor to consider when choosing a tin can sealer machine. Tin can sealer machines can vary widely in price, depending on the size, capacity, and features of the machine. It is important to consider your budget and choose a machine that fits within your financial constraints while still meeting your production needs.

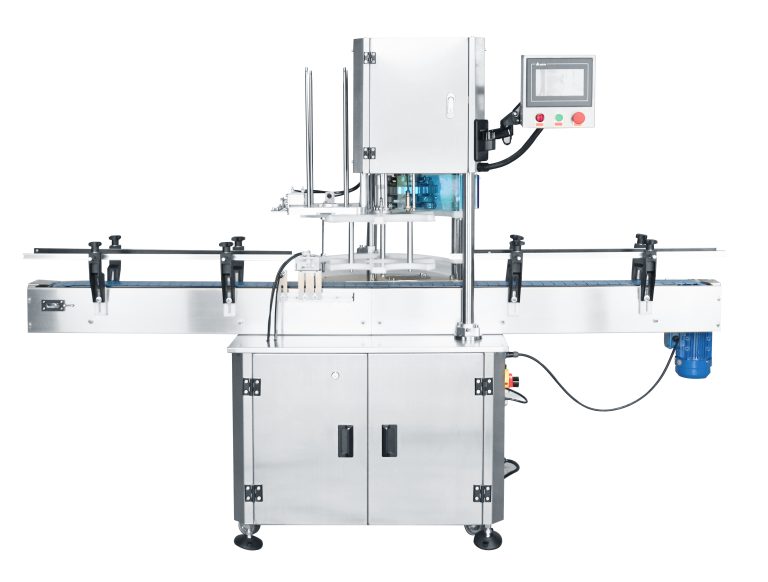

When selecting a tin can sealer machine, it is also important to consider the speed and efficiency of the machine. Fully automatic machines are typically faster and more efficient than manual or semi-automatic machines, which can help to increase productivity and reduce labor costs. However, fully automatic machines are also more expensive and may require more maintenance than manual or semi-automatic machines.

Finally, it is important to consider the reputation of the manufacturer when choosing a tin can sealer machine. Look for a manufacturer with a proven track record of producing high-quality machines that are reliable and durable. Reading reviews and testimonials from other customers can help you determine the reliability and quality of a particular manufacturer’s machines.

In conclusion, choosing the right tin can sealer machine for your production is a crucial decision that can have a significant impact on the efficiency and productivity of your operation. By considering factors such as production volume, can size and material, cost, speed and efficiency, and manufacturer reputation, you can select a machine that meets your production needs and fits within your budget. Take the time to research and compare different machines to find the best option for your specific requirements.