Table of Contents

Benefits of Using an Automatic Syrup Bottle Liquid Filling Machine

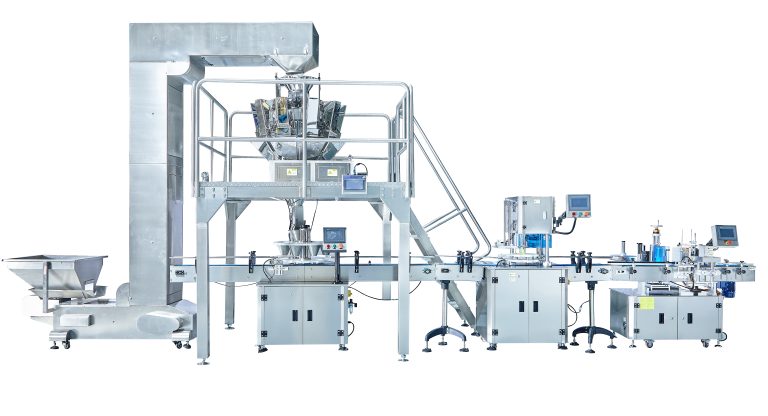

Automatic syrup bottle liquid filling machines are a valuable asset for businesses in the food and beverage industry. These machines offer a range of benefits that can help streamline production processes, improve efficiency, and ultimately increase profitability. In this article, we will explore some of the key advantages of using an automatic syrup bottle liquid filling machine.

One of the primary benefits of using an automatic syrup bottle liquid filling machine is the speed and accuracy it offers. These machines are designed to fill bottles quickly and precisely, ensuring that each bottle is filled to the exact same level every time. This level of consistency is essential for maintaining product quality and meeting customer expectations. By automating the filling process, businesses can significantly increase their production output and reduce the risk of human error.

In addition to speed and accuracy, automatic syrup bottle liquid filling machines also offer a high level of versatility. These machines can be easily adjusted to accommodate different bottle sizes and fill volumes, making them suitable for a wide range of products. Whether you are filling small sample bottles or large bulk containers, an automatic syrup bottle liquid filling machine can be customized to meet your specific needs. This flexibility allows businesses to easily adapt to changing production requirements and expand their product offerings.

Another key benefit of using an automatic syrup bottle liquid filling machine is the cost savings it can provide. While the initial investment in a filling machine may seem significant, the long-term savings can be substantial. By automating the filling process, businesses can reduce labor costs, minimize product waste, and increase overall efficiency. Additionally, the consistent filling provided by these machines can help reduce product recalls and customer complaints, saving businesses both time and money in the long run.

Furthermore, automatic syrup bottle liquid filling machines can also improve workplace safety. Manual filling processes can be physically demanding and repetitive, leading to an increased risk of injuries and strain on workers. By automating the filling process, businesses can create a safer work environment for their employees and reduce the likelihood of workplace accidents. This not only protects the well-being of workers but also helps businesses avoid costly workers’ compensation claims and downtime.

In conclusion, the benefits of using an automatic syrup bottle liquid filling machine are clear. From increased speed and accuracy to improved versatility and cost savings, these machines offer a range of advantages that can help businesses in the food and beverage industry thrive. By investing in an automatic filling machine, businesses can streamline their production processes, enhance product quality, and ultimately boost their bottom line. If you are looking to improve efficiency and productivity in your business, consider the many benefits of using an automatic syrup bottle liquid filling machine.

How to Choose the Right Automatic Syrup Bottle Liquid Filling Machine for Your Business

When it comes to running a business that involves bottling syrup, having the right equipment is crucial to ensuring efficiency and productivity. One piece of equipment that can greatly benefit your operation is an automatic syrup bottle liquid filling machine. These machines are designed to accurately fill bottles with syrup, reducing the risk of spills and waste. However, with so many options available on the market, it can be overwhelming to choose the right one for your business. In this article, we will discuss some key factors to consider when selecting an automatic syrup bottle liquid filling machine.

First and foremost, it is important to consider the size and capacity of the machine. The size of the machine will depend on the volume of syrup you need to fill on a daily basis. If you have a small operation, a smaller machine may be sufficient. However, if you have a larger operation, you will need a machine with a higher capacity to meet your production needs. It is also important to consider the physical dimensions of the machine to ensure it will fit in your workspace.

Another important factor to consider is the speed and efficiency of the machine. A faster machine will allow you to fill more bottles in less time, increasing your overall productivity. Look for a machine that offers adjustable filling speeds so you can customize the machine to meet your specific needs. Additionally, consider the accuracy of the machine’s filling mechanism to ensure that each bottle is filled to the correct level.

In addition to speed and capacity, it is important to consider the ease of use and maintenance of the machine. Look for a machine that is user-friendly and easy to operate, as this will reduce the amount of training required for your staff. Additionally, consider the maintenance requirements of the machine to ensure that it can be easily cleaned and serviced to keep it running smoothly.

When selecting an automatic syrup bottle liquid filling machine, it is also important to consider the type of syrup you will be filling. Some machines are designed specifically for thicker syrups, while others are better suited for thinner liquids. Make sure to choose a machine that is compatible with the viscosity of your syrup to ensure accurate and efficient filling.

Finally, consider the reputation of the manufacturer when selecting an automatic syrup bottle liquid filling machine. Look for a reputable manufacturer with a track record of producing high-quality machines that are built to last. Reading reviews and testimonials from other customers can help you gauge the reliability and performance of the machine.

In conclusion, choosing the right automatic syrup bottle liquid filling machine for your business is a crucial decision that can impact the efficiency and productivity of your operation. Consider factors such as size, capacity, speed, ease of use, maintenance requirements, syrup viscosity, and manufacturer reputation when making your selection. By taking the time to research and evaluate your options, you can find a machine that meets your specific needs and helps you streamline your syrup bottling process.

Maintenance Tips for Keeping Your Automatic Syrup Bottle Liquid Filling Machine Running Smoothly

Automatic syrup bottle liquid filling machines are essential equipment for businesses in the food and beverage industry. These machines are designed to accurately fill bottles with syrup, ensuring consistency in product quality and reducing the risk of spills or waste. To keep your automatic syrup bottle liquid filling machine running smoothly and efficiently, it is important to follow a regular maintenance schedule. In this article, we will discuss some maintenance tips to help you keep your machine in top condition.

One of the most important maintenance tasks for your automatic syrup bottle liquid filling machine is regular cleaning. Over time, syrup residue can build up on the machine’s components, leading to clogs and malfunctions. To prevent this, it is recommended to clean the machine after each use. Use a mild detergent and warm water to clean the machine thoroughly, paying special attention to areas where syrup may accumulate. Additionally, it is important to sanitize the machine regularly to prevent bacterial growth and contamination of your product.

In addition to regular cleaning, it is important to inspect the machine for any signs of wear or damage. Check the seals, gaskets, and hoses for cracks or leaks, and replace them if necessary. Inspect the machine’s moving parts, such as the conveyor belts and pumps, for any signs of wear or misalignment. By catching and addressing these issues early, you can prevent more serious problems from occurring and extend the lifespan of your machine.

Another important maintenance task for your automatic syrup bottle liquid filling machine is lubrication. Proper lubrication of the machine’s moving parts is essential to reduce friction and wear, ensuring smooth operation. Consult the manufacturer’s guidelines for the recommended type and frequency of lubrication for your machine. Be sure to use only approved lubricants to prevent damage to the machine’s components.

Regular calibration of your automatic syrup bottle liquid filling machine is also crucial to ensure accurate filling volumes. Over time, the machine’s sensors and controls may drift out of alignment, leading to inaccuracies in filling. To prevent this, it is recommended to calibrate the machine regularly using a calibrated scale or volume measurement device. By maintaining accurate filling volumes, you can ensure consistent product quality and reduce the risk of product recalls.

Finally, it is important to train your staff on proper machine operation and maintenance procedures. Ensure that all operators are familiar with the machine’s controls and safety features, and provide training on how to perform routine maintenance tasks. By empowering your staff with the knowledge and skills to properly maintain the machine, you can prevent costly downtime and ensure the continued efficiency of your production line.

In conclusion, regular maintenance is essential for keeping your automatic syrup bottle liquid filling machine running smoothly and efficiently. By following a regular cleaning schedule, inspecting the machine for wear and damage, lubricating moving parts, calibrating the machine, and training your staff on proper maintenance procedures, you can extend the lifespan of your machine and ensure consistent product quality. By investing time and effort into maintaining your machine, you can avoid costly repairs and downtime, ultimately improving the overall efficiency of your production line.