Table of Contents

Benefits of Using a Powder Filling Line for Bottles and Cans

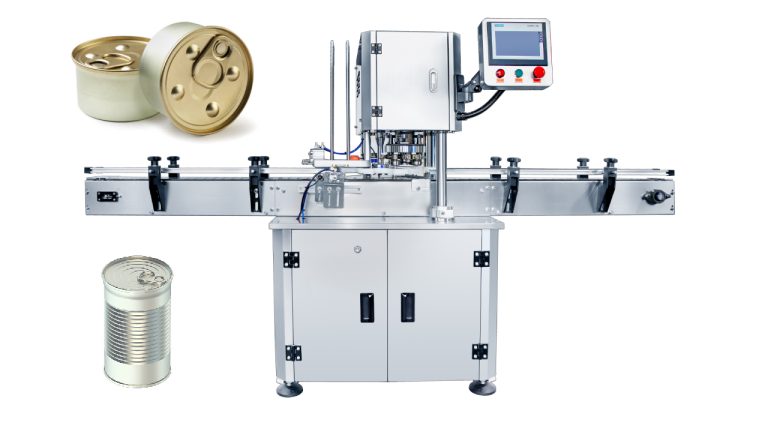

A powder filling line for bottles and cans is a crucial piece of equipment for companies in the food, pharmaceutical, and cosmetic industries. This automated system is designed to efficiently fill containers with powdered substances, such as spices, protein powders, pharmaceuticals, and more. By utilizing a powder filling line, businesses can streamline their production process, increase efficiency, and ensure consistent product quality.

One of the key benefits of using a powder filling line for bottles and cans is the speed and accuracy it offers. These machines are capable of filling a large number of containers in a short amount of time, significantly reducing production time and labor costs. Additionally, the automated nature of these systems ensures precise filling levels, minimizing product waste and ensuring consistent product quality.

Another advantage of using a powder filling line is the flexibility it provides. These machines can be easily adjusted to accommodate different container sizes and shapes, as well as varying fill volumes. This versatility allows companies to quickly adapt to changing production needs and easily switch between different products without the need for extensive retooling.

In addition to speed and flexibility, powder filling lines also offer improved hygiene and safety benefits. These machines are designed to meet strict hygiene standards, with features such as stainless steel construction and easy-to-clean surfaces. This helps to prevent contamination and ensure product safety, particularly important in industries such as pharmaceuticals and food production where cleanliness is paramount.

Furthermore, using a powder filling line can help companies reduce product loss and waste. These machines are equipped with advanced technology that ensures accurate filling levels, minimizing overfilling and spillage. This not only helps to reduce costs associated with wasted product but also improves overall efficiency and productivity.

Additionally, powder filling lines can help companies meet regulatory requirements and quality standards. These machines are designed to comply with industry regulations and can be equipped with features such as checkweighers and metal detectors to ensure product quality and safety. By using a powder filling line, companies can demonstrate their commitment to producing high-quality products that meet industry standards.

Overall, the benefits of using a powder filling line for bottles and cans are numerous. From increased speed and efficiency to improved hygiene and safety, these machines offer a range of advantages that can help companies streamline their production process and enhance product quality. By investing in a powder filling line, businesses can stay competitive in their industry, meet regulatory requirements, and ultimately improve their bottom line.

How to Choose the Right Powder Filling Line for Bottles and Cans

A powder filling line for bottles and cans is a crucial piece of equipment for companies in industries such as pharmaceuticals, food and beverage, and cosmetics. This automated system is designed to accurately fill containers with powdered substances, ensuring consistency and efficiency in the production process. With various options available on the market, choosing the right powder filling line for bottles and cans can be a daunting task. In this article, we will discuss the factors to consider when selecting a powder filling line to meet your specific needs.

One of the first things to consider when choosing a powder filling line is the type of containers you will be filling. Different machines are designed to handle bottles, cans, or other types of containers, so it is important to select a system that is compatible with the containers you will be using. Additionally, consider the size and shape of the containers, as this will impact the design and capabilities of the powder filling line.

Another important factor to consider is the type of powder you will be filling. Some powders are free-flowing and easy to handle, while others may be sticky or prone to clumping. The characteristics of the powder will determine the type of filling mechanism needed, as well as the level of precision required in the filling process. Be sure to communicate the properties of your powder to the manufacturer to ensure that the powder filling line is equipped to handle it effectively.

In addition to the type of containers and powder, consider the production volume and speed requirements of your operation. Powder filling lines come in a range of speeds and capacities, so it is important to select a system that can keep up with your production demands. Consider factors such as the number of containers to be filled per minute, as well as any future growth projections that may impact your production needs.

Furthermore, consider the level of automation and customization required for your powder filling line. Some systems offer basic manual operation, while others are fully automated with features such as automatic container handling, filling, and capping. Depending on your production requirements and budget, you may opt for a more basic system or invest in a fully automated solution to streamline your production process.

When selecting a powder filling line for bottles and cans, it is also important to consider the overall reliability and reputation of the manufacturer. Look for a company with a proven track record of delivering high-quality equipment and excellent customer service. Additionally, consider factors such as warranty coverage, maintenance and support services, and the availability of spare parts to ensure that your powder filling line will continue to operate smoothly for years to come.

In conclusion, choosing the right powder filling line for bottles and cans requires careful consideration of factors such as container type, powder properties, production volume, automation level, and manufacturer reputation. By taking these factors into account and working closely with a reputable manufacturer, you can select a powder filling line that meets your specific needs and helps to optimize your production process.