Table of Contents

Benefits of Using Aluminum Container Sealers in Food Packaging

Aluminum container sealers have become increasingly popular in the food packaging industry due to their numerous benefits. These sealers are used to create a tight seal on aluminum containers, ensuring that the contents remain fresh and free from contamination. In this article, we will explore the benefits of using aluminum container sealers in food packaging.

One of the main advantages of using aluminum container sealers is their ability to provide a secure seal that prevents leaks and spills. This is especially important when packaging liquids or semi-liquids, as any leakage can lead to product wastage and potential contamination. Aluminum container sealers create a hermetic seal that keeps the contents safe and secure, giving consumers peace of mind when purchasing packaged food products.

In addition to preventing leaks, aluminum container sealers also help to extend the shelf life of food products. By creating an airtight seal, these sealers prevent oxygen and moisture from entering the container, which can cause food to spoil. This helps to preserve the freshness and quality of the packaged food, ensuring that consumers receive a product that meets their expectations.

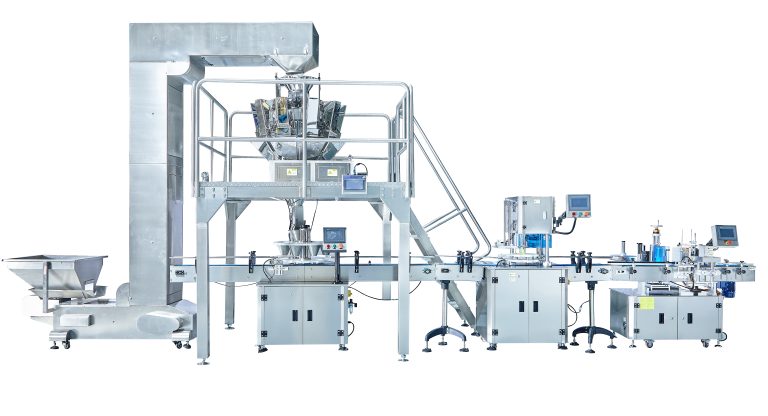

Another benefit of using aluminum container sealers is their versatility. These sealers can be used on a wide range of aluminum containers, including cans, trays, and tubs. This makes them suitable for packaging a variety of food products, from beverages to snacks to ready-to-eat meals. The flexibility of aluminum container sealers makes them a cost-effective solution for food manufacturers looking to package their products efficiently and securely.

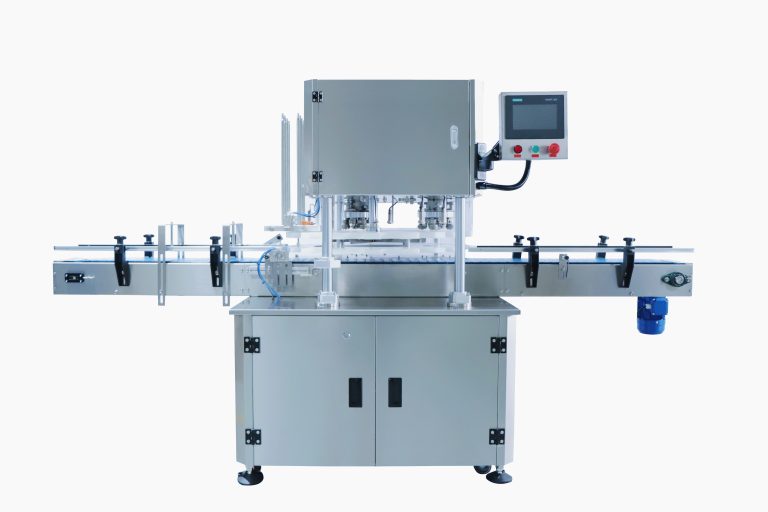

Furthermore, aluminum container sealers are easy to use and require minimal maintenance. Once the sealer is set up and calibrated, it can be operated with minimal training, reducing the need for skilled labor. This helps to streamline the packaging process and increase productivity, saving time and resources for food manufacturers.

In addition to their practical benefits, aluminum container sealers are also environmentally friendly. Aluminum is a recyclable material, which means that the containers sealed with aluminum container sealers can be easily recycled after use. This helps to reduce waste and minimize the environmental impact of food packaging, making aluminum container sealers a sustainable choice for food manufacturers.

Overall, the benefits of using aluminum container sealers in food packaging are clear. From preventing leaks and extending shelf life to their versatility and ease of use, these sealers offer a range of advantages for food manufacturers. By investing in aluminum container sealers, food manufacturers can improve the quality and safety of their packaged products, while also reducing waste and supporting sustainability efforts in the industry.

How to Choose the Right Aluminum Container Sealer for Your Factory

Aluminum container sealers are essential equipment for factories that package products in aluminum containers. These sealers ensure that the containers are properly sealed to maintain the freshness and quality of the products inside. Choosing the right aluminum container sealer for your factory is crucial to ensure efficient and effective packaging processes.

When selecting an aluminum container sealer for your factory, there are several factors to consider. The first factor to consider is the type of aluminum containers you will be sealing. Different sealers are designed to work with specific types and sizes of containers, so it is important to choose a sealer that is compatible with the containers you use in your factory.

Another important factor to consider is the sealing method used by the sealer. There are different sealing methods available, including induction sealing, hot air sealing, and pressure sealing. Each method has its own advantages and disadvantages, so it is important to choose a sealer that uses a sealing method that is suitable for the type of products you package in your factory.

The speed and efficiency of the sealer are also important considerations. A fast and efficient sealer can help increase productivity and reduce packaging time, which can ultimately lead to cost savings for your factory. Look for sealers that have a high sealing speed and can handle a large volume of containers per hour.

Durability and reliability are also key factors to consider when choosing an aluminum container sealer for your factory. You want a sealer that is built to last and can withstand the rigors of daily use in a factory setting. Look for sealers made from high-quality materials and that are backed by a warranty to ensure that you are investing in a reliable piece of equipment.

Ease of use and maintenance are also important considerations when choosing an aluminum container sealer for your factory. Look for sealers that are easy to operate and require minimal maintenance to keep them running smoothly. Consider the availability of spare parts and technical support when choosing a sealer to ensure that you can quickly address any issues that may arise.

In addition to these factors, it is also important to consider the cost of the sealer and how it fits into your factory’s budget. While it is important to invest in a high-quality sealer, you also want to make sure that it is affordable and offers good value for money. Compare prices and features of different sealers to find one that meets your needs and budget.

In conclusion, choosing the right aluminum container sealer for your factory is a crucial decision that can impact the efficiency and effectiveness of your packaging processes. Consider factors such as the type of containers you use, sealing method, speed and efficiency, durability and reliability, ease of use and maintenance, and cost when selecting a sealer for your factory. By carefully evaluating these factors, you can choose a sealer that meets your needs and helps streamline your packaging operations.

Maintenance Tips for Aluminum Container Sealers in a Factory Setting

Aluminum container sealers play a crucial role in the packaging industry, ensuring that products are securely sealed and protected during transportation and storage. In a factory setting, these sealers are subjected to heavy use and can experience wear and tear over time. To ensure the longevity and efficiency of your aluminum container sealers, it is important to implement regular maintenance practices. In this article, we will discuss some key maintenance tips for aluminum container sealers in a factory setting.

One of the most important maintenance practices for aluminum container sealers is regular cleaning. Dust, debris, and product residue can build up on the sealer’s components, leading to decreased performance and potential damage. To clean your aluminum container sealer, start by unplugging the machine and allowing it to cool down. Use a soft brush or cloth to remove any visible debris from the sealing components. You can also use a mild detergent solution to clean more stubborn residue. Be sure to dry the sealer thoroughly before plugging it back in.

In addition to regular cleaning, it is important to inspect the sealing components for any signs of wear or damage. Check the sealing bars, heating elements, and pressure rollers for any cracks, dents, or other issues that may affect the sealer’s performance. If you notice any damage, it is important to replace the affected components promptly to prevent further damage to the sealer.

Another important maintenance tip for aluminum container sealers is to lubricate the moving parts regularly. Over time, the moving parts of the sealer can become stiff or worn, leading to decreased efficiency and potential breakdowns. To lubricate your aluminum container sealer, use a high-quality lubricant recommended by the manufacturer. Apply the lubricant to the moving parts according to the manufacturer’s instructions to ensure smooth operation.

In addition to regular cleaning, inspection, and lubrication, it is important to calibrate your aluminum container sealer regularly. Calibration ensures that the sealer is operating at the correct temperature, pressure, and speed to achieve a proper seal. Follow the manufacturer’s guidelines for calibrating your sealer, and make any necessary adjustments to ensure optimal performance.

Finally, it is important to train your staff on proper operating procedures and maintenance practices for aluminum container sealers. Proper training can help prevent damage to the sealers and ensure that they are being used efficiently. Provide your staff with clear instructions on how to operate the sealers, as well as how to perform basic maintenance tasks. Encourage them to report any issues or concerns with the sealers promptly so that they can be addressed before they escalate.

In conclusion, regular maintenance is essential for ensuring the longevity and efficiency of aluminum container sealers in a factory setting. By implementing regular cleaning, inspection, lubrication, calibration, and staff training, you can help prevent breakdowns and ensure that your sealers are operating at their best. Remember to follow the manufacturer’s guidelines for maintenance and seek professional assistance if you encounter any issues beyond your expertise. With proper maintenance practices in place, your aluminum container sealers can continue to provide reliable sealing for your products.