Table of Contents

Benefits of Using Cereals Powder Filling Seaming Labeling Machine

Cereals powder filling seaming labeling machines are essential equipment in the food packaging industry. These machines offer numerous benefits that can help businesses streamline their production processes and improve overall efficiency. One of the key advantages of using a cereals powder filling seaming labeling machine is the high level of accuracy and precision it provides. These machines are designed to fill containers with cereals powder to a specific weight or volume, ensuring consistency in every package.

In addition to accuracy, cereals powder filling seaming labeling machines are also highly efficient. These machines can fill and seal hundreds of containers per minute, significantly increasing production output. This high level of efficiency can help businesses meet customer demand and reduce lead times, ultimately improving overall profitability.

Another benefit of using a cereals powder filling seaming labeling machine is the reduction in labor costs. These machines are fully automated, requiring minimal human intervention. This means that businesses can operate with fewer staff members, saving on labor expenses. Additionally, the automation provided by these machines reduces the risk of human error, ensuring that each package is filled and sealed correctly every time.

Cereals powder filling seaming labeling machines also offer versatility in packaging options. These machines can accommodate a wide range of container sizes and shapes, allowing businesses to package their cereals powder in various formats. This flexibility is essential for businesses looking to cater to different market segments and packaging requirements.

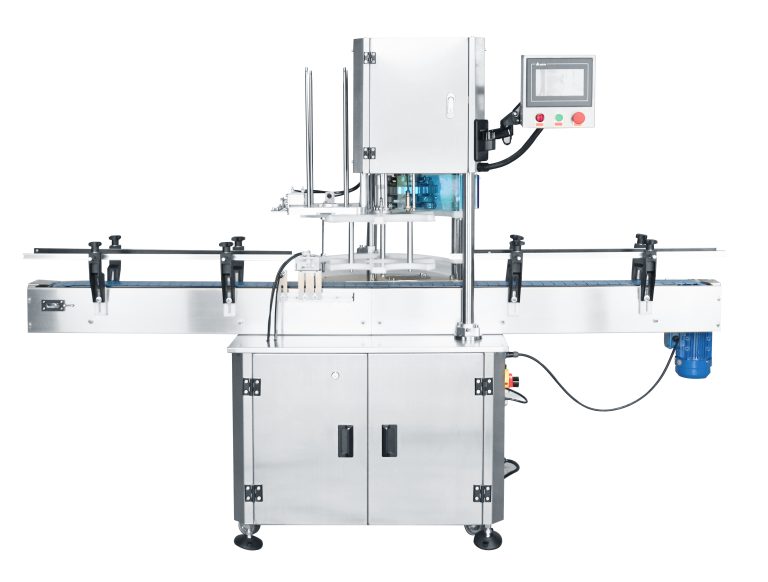

Furthermore, cereals powder filling seaming labeling machines are designed for easy maintenance and cleaning. These machines are constructed with high-quality materials that are durable and resistant to corrosion. This ensures that the machines have a long lifespan and require minimal maintenance over time. Additionally, the design of these machines allows for easy access to all components, making cleaning and maintenance tasks quick and straightforward.

One of the most significant benefits of using a cereals powder filling seaming labeling machine is the improvement in product quality. These machines are equipped with advanced technology that ensures precise filling and sealing, resulting in a consistent and professional-looking final product. This level of quality can help businesses build a strong brand reputation and increase customer loyalty.

Overall, cereals powder filling seaming labeling machines offer numerous benefits that can help businesses improve their production processes and increase profitability. From accuracy and efficiency to versatility and product quality, these machines are essential equipment for any food packaging operation. By investing in a cereals powder filling seaming labeling machine, businesses can streamline their operations, reduce costs, and deliver high-quality products to their customers.

How to Choose the Right Cereals Powder Filling Seaming Labeling Machine for Your Business

Cereals powder filling, seaming, and labeling machines are essential equipment for businesses in the food industry. These machines automate the process of filling containers with cereals powder, sealing them, and labeling them for retail sale. Choosing the right machine for your business is crucial to ensure efficiency, accuracy, and consistency in your production process.

When selecting a cereals powder filling, seaming, and labeling machine, there are several factors to consider. The first consideration is the production capacity of the machine. You need to determine the volume of cereals powder you need to fill and seal per hour to meet your production requirements. Look for a machine that can handle your desired production capacity without compromising on speed or quality.

Another important factor to consider is the type of containers you will be filling and sealing. Different machines are designed to handle specific types of containers, such as bottles, jars, or pouches. Make sure the machine you choose is compatible with the containers you use in your production process to avoid any issues with filling and sealing.

Additionally, consider the level of automation you need in a cereals powder filling, seaming, and labeling machine. Some machines are fully automated, requiring minimal human intervention, while others may require more manual operation. Choose a machine that aligns with your production process and workforce capabilities to maximize efficiency and productivity.

It is also essential to consider the space available in your production facility for the machine. Measure the dimensions of the machine and ensure it can fit comfortably in your workspace without causing any disruptions to your production process. Additionally, consider the power requirements of the machine and ensure your facility can support its electrical needs.

When evaluating different cereals powder filling, seaming, and labeling machines, consider the reputation and reliability of the manufacturer. Look for a reputable manufacturer with a track record of producing high-quality machines that are durable and reliable. Read reviews and testimonials from other customers to gauge the performance and reliability of the machine you are considering.

Furthermore, consider the maintenance and servicing requirements of the machine. Choose a machine that is easy to clean and maintain to ensure smooth operation and longevity. Look for a manufacturer that offers comprehensive support and servicing options to address any issues that may arise during the machine’s lifespan.

In conclusion, choosing the right cereals powder filling, seaming, and labeling machine for your business is a critical decision that can impact your production process and overall efficiency. Consider factors such as production capacity, container compatibility, automation level, space requirements, manufacturer reputation, and maintenance needs when selecting a machine. By carefully evaluating these factors and choosing a machine that meets your specific requirements, you can streamline your production process and enhance the quality of your cereals powder products.