Table of Contents

Beneficios de utilizar máquinas llenadoras de botellas de vidrio para salsa alimentaria

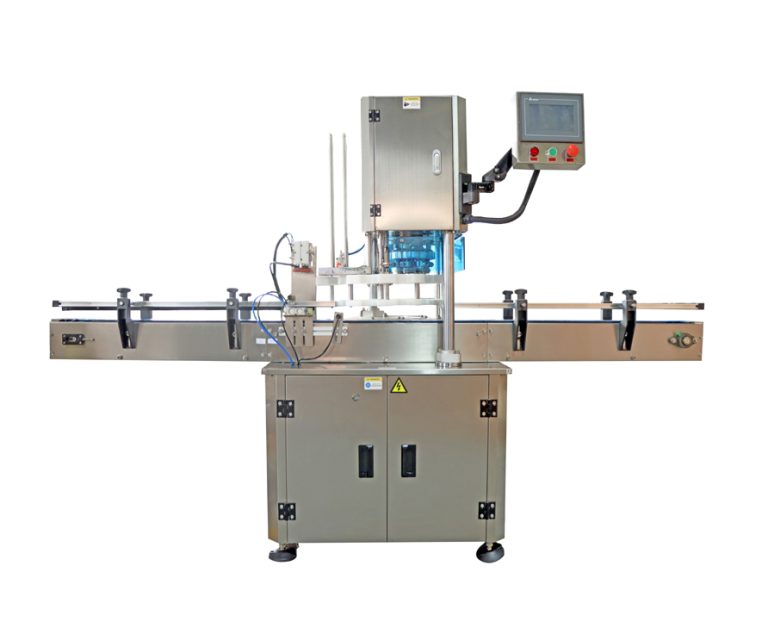

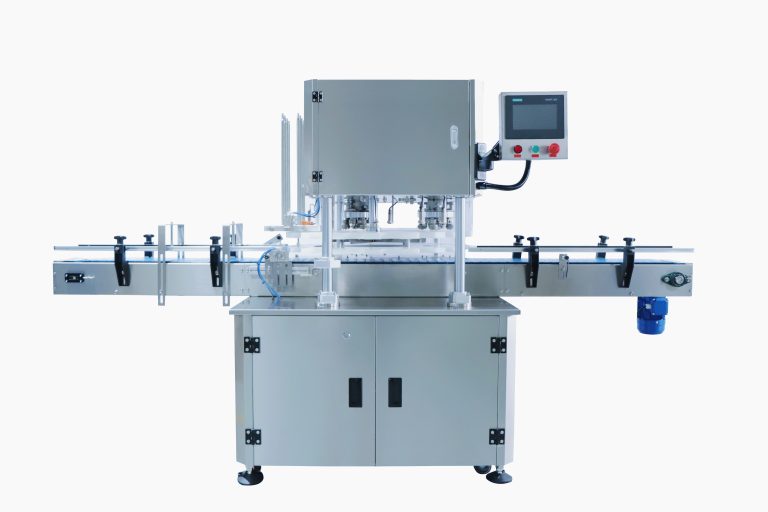

Las máquinas llenadoras y taponadoras de botellas de vidrio para salsas alimenticias son equipos esenciales en la industria alimentaria para envasar de manera eficiente salsas, aderezos y otros productos líquidos. Estas máquinas ofrecen numerosos beneficios a los fabricantes de alimentos, incluido un aumento de la productividad, una mejor calidad del producto y una reducción de los costos de mano de obra.

Una de las principales ventajas de utilizar máquinas llenadoras de botellas de vidrio para salsas alimentarias es su capacidad para automatizar el proceso de llenado. Estas máquinas están diseñadas para llenar botellas con precisión con una cantidad precisa de producto, garantizando la consistencia en cada lote. Esta automatización no solo acelera el proceso de producción sino que también reduce el riesgo de error humano, lo que da como resultado un producto final de mayor calidad.

Además de mejorar la productividad, las máquinas llenadoras de botellas de vidrio para salsas alimentarias también ayudan a mantener la calidad del producto. Al llenar las botellas con una cantidad constante de salsa, los fabricantes pueden garantizar que cada botella contenga la proporción correcta de ingredientes. Esta consistencia es esencial para mantener el sabor y la textura del producto, así como para cumplir con los requisitos reglamentarios de etiquetado y envasado.

Además, las máquinas llenadoras de botellas de vidrio para salsas alimenticias pueden ayudar a reducir los costos de mano de obra al minimizar la necesidad de mano de obra en el proceso de producción. Con capacidades automatizadas de llenado y taponado, estas máquinas pueden manejar un gran volumen de botellas con una mínima intervención humana. Esto no solo ahorra tiempo sino que también reduce el riesgo de lesiones y accidentes en el lugar de trabajo.

Otro beneficio de utilizar máquinas llenadoras de botellas de vidrio para salsa alimentaria es su versatilidad. Estas máquinas se pueden ajustar fácilmente para adaptarse a diferentes tamaños y formas de botellas, así como a una variedad de viscosidades de productos. Esta flexibilidad permite a los fabricantes cambiar rápidamente entre diferentes productos sin la necesidad de grandes cambios de herramientas o tiempo de inactividad, lo que los hace ideales para la producción de lotes pequeños o productos de temporada.

Además, las máquinas llenadoras de botellas de vidrio para salsa alimentaria están diseñadas para cumplir con estrictos estándares de higiene y seguridad en la industria alimentaria. Estas máquinas están construidas con materiales aptos para uso alimentario que son fáciles de limpiar y desinfectar, lo que reduce el riesgo de contaminación y garantiza la seguridad del consumidor final. Al invertir en máquinas llenadoras de alta calidad, los fabricantes pueden demostrar su compromiso de producir productos seguros y de alta calidad.

En general, las máquinas llenadoras y taponadoras de botellas de vidrio para salsas alimenticias ofrecen numerosos beneficios a los fabricantes de alimentos, incluido un aumento de la productividad y una mejora del producto. calidad, costos laborales reducidos, versatilidad y cumplimiento de los estándares de la industria. Al invertir en estas máquinas, los fabricantes pueden optimizar su proceso de producción, mejorar la consistencia del producto y, en última instancia, mejorar sus resultados. Con el equipo adecuado, los fabricantes de alimentos pueden satisfacer la creciente demanda de salsas y aderezos de alta calidad mientras mantienen la eficiencia y rentabilidad en sus operaciones.

Importancia de las máquinas tapadoras Twist Off en la línea de producción de salsas alimenticias

En la industria alimentaria, el embalaje de los productos juega un papel crucial para garantizar la calidad y seguridad de los artículos que se venden. Un aspecto importante del envasado es el sellado de los recipientes, en particular de las botellas de vidrio, que se utilizan habitualmente para salsas y condimentos. Las máquinas taponadoras de rosca son esenciales en la línea de producción de botellas de vidrio para salsas alimenticias, ya que proporcionan un sello seguro y hermético que ayuda a preservar la frescura y el sabor del producto.

Estas máquinas están diseñadas para llenar eficientemente botellas de vidrio con salsa y luego séllelos con una tapa giratoria. El proceso está automatizado, lo que garantiza consistencia y precisión en el sellado de cada botella. Esto es importante para mantener la calidad del producto y prevenir cualquier contaminación o deterioro.

Uno de los beneficios clave de utilizar máquinas tapadoras por torsión en la producción de salsas alimenticias es la velocidad y eficiencia que ofrecen. Estas máquinas pueden tapar cientos de botellas por minuto, lo que aumenta significativamente la producción y reduce los costos de mano de obra. Esto es especialmente importante para los fabricantes de alimentos a gran escala que necesitan satisfacer una gran demanda y mantener una ventaja competitiva en el mercado.

Otra ventaja importante de las máquinas tapadoras por torsión es su versatilidad. Estas máquinas se pueden ajustar fácilmente para adaptarse a diferentes tamaños de botellas y tipos de tapas, lo que las hace adecuadas para una amplia gama de productos de salsas alimenticias. Esta flexibilidad permite a los fabricantes cambiar rápidamente entre diferentes productos sin la necesidad de grandes cambios de herramientas o tiempos de inactividad.

Además de la velocidad y la versatilidad, las máquinas taponadoras por torsión también garantizan la seguridad e integridad del producto. El sello hermético creado por estas máquinas ayuda a prevenir la contaminación y el deterioro, extendiendo la vida útil de la salsa alimenticia. Esto es crucial para garantizar que los consumidores reciban un producto de alta calidad que cumpla con los estándares y regulaciones de seguridad.

Además, las máquinas tapadoras por torsión están diseñadas para ser fáciles de operar y mantener. Están equipados con controles fáciles de usar y están construidos para soportar los rigores de la producción continua. Esto reduce el riesgo de tiempo de inactividad y garantiza que la línea de producción funcione sin problemas y de manera eficiente.

En general, las máquinas taponadoras por torsión desempeñan un papel vital en la línea de producción de salsas alimenticias al proporcionar una solución de sellado rápida, eficiente y confiable para botellas de vidrio. Su capacidad para sellar botellas de forma rápida y segura ayuda a mantener la calidad y frescura del producto, al mismo tiempo que aumenta la producción y reduce los costos. Con su versatilidad y facilidad de uso, estas máquinas son un componente esencial de cualquier operación de fabricación de salsa alimenticia.