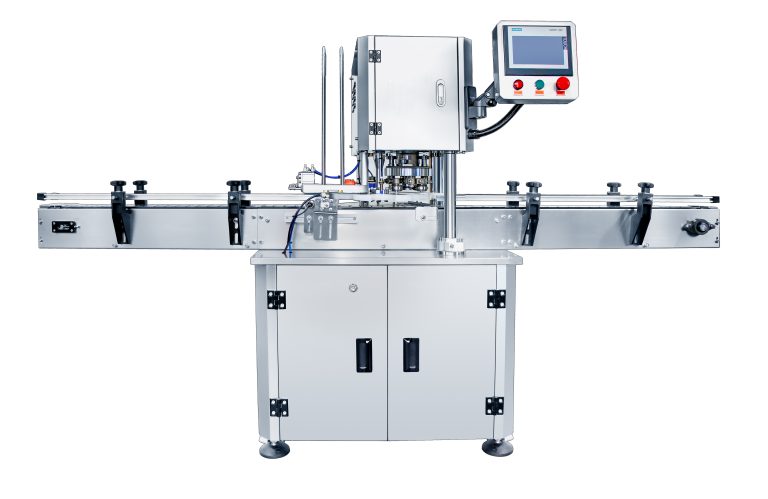

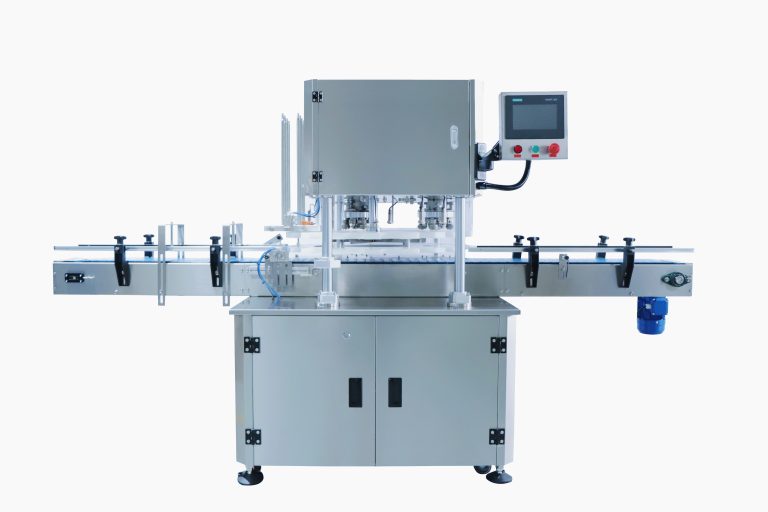

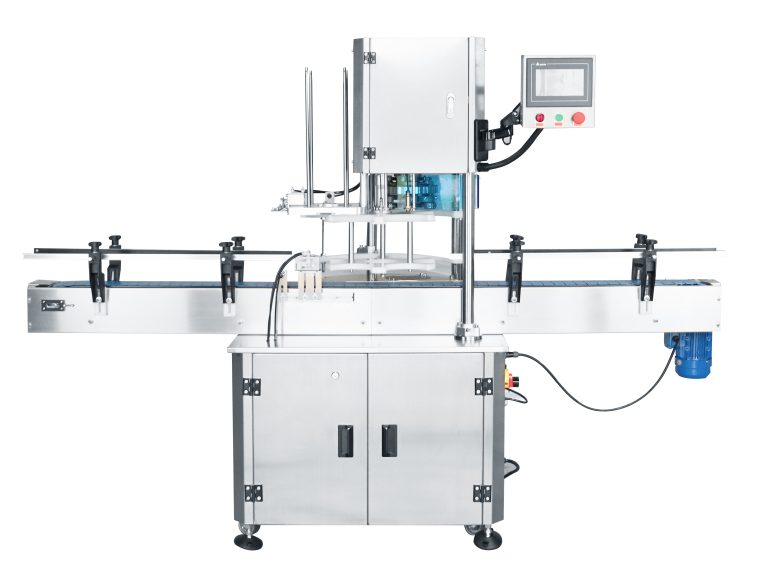

Servo twist-off capping machines are revolutionary tools that can significantly enhance the accuracy and consistency of the capping process.

The advanced technology incorporated in these machines ensures precise control over the torque and speed applied during cap twisting. This results in each cap being fastened with the exact same level of tightness, eliminating variations and ensuring a uniform seal.

The use of high-quality sensors and feedback systems allows for real-time monitoring and adjustment. If any deviation from the desired parameters is detected, the machine instantly corrects it, maintaining the accuracy and consistency of the capping operation.

The consistent application of torque helps prevent over-tightening or under-tightening of caps. Over-tightening can cause damage to the container or cap, while under-tightening can lead to leaks or compromised product integrity. With servo twist-off capping machines, these issues are avoided.

The machines are designed to handle a wide range of cap and container sizes and types with ease. Regardless of the variations, they maintain the same level of accuracy and consistency, providing reliable performance across different production runs.

Furthermore, the repeatability of the capping process ensures that every batch of products has the same high-quality capping, which is crucial for maintaining brand reputation and customer satisfaction.

In conclusion, by investing in servo twist-off capping machines, businesses can achieve superior accuracy and consistency in their capping operations, leading to improved product quality and reduced risks associated with packaging.