Table of Contents

Benefits of Using a Simple Nitrogen Flushing Can Seamer Machine

In the food and beverage industry, packaging plays a crucial role in preserving the quality and freshness of products. One popular method used to extend the shelf life of canned goods is nitrogen flushing. Nitrogen flushing involves replacing the air inside a can with nitrogen gas before sealing it. This process helps to prevent oxidation and microbial growth, keeping the contents of the can fresh for a longer period of time.

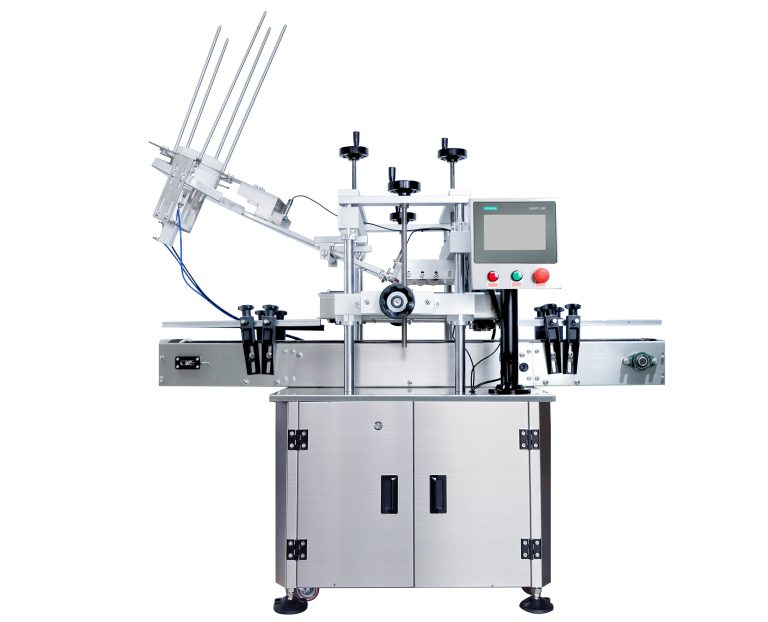

One of the key tools used in nitrogen flushing is a can seamer machine. This machine is designed to seal cans quickly and efficiently, ensuring that the nitrogen gas remains inside the can to preserve the product. While there are many different types of can seamer machines available on the market, a simple nitrogen flushing can seamer machine offers several benefits for businesses looking to improve their packaging process.

One of the main benefits of using a simple nitrogen flushing can seamer machine is its ease of use. These machines are designed to be user-friendly, with intuitive controls and minimal setup required. This makes it easy for operators to quickly learn how to use the machine and start sealing cans with nitrogen gas. Additionally, simple nitrogen flushing can seamer machines are typically compact in size, making them ideal for businesses with limited space in their packaging area.

Another benefit of using a simple nitrogen flushing can seamer machine is its efficiency. These machines are capable of sealing a large number of cans in a short amount of time, helping businesses to increase their production output. This can be especially beneficial for companies that have high demand for their canned products and need to package them quickly to meet customer needs.

In addition to improving efficiency, a simple nitrogen flushing can seamer machine can also help to reduce waste. By using nitrogen gas to flush out the air inside the can, businesses can extend the shelf life of their products and reduce the likelihood of spoilage. This can result in fewer products being thrown away due to expiration, ultimately saving businesses money in the long run.

Furthermore, using a simple nitrogen flushing can seamer machine can help businesses to maintain the quality and freshness of their products. By sealing cans with nitrogen gas, businesses can create a protective barrier that helps to prevent contamination and preserve the flavor and texture of the contents. This can lead to higher customer satisfaction and repeat purchases, as consumers are more likely to buy products that are fresh and of high quality.

Overall, a simple nitrogen flushing can seamer machine offers numerous benefits for businesses in the food and beverage industry. From its ease of use and efficiency to its ability to reduce waste and maintain product quality, this machine can help businesses to improve their packaging process and deliver fresh, high-quality products to consumers. By investing in a simple nitrogen flushing can seamer machine, businesses can enhance their production capabilities and stay competitive in the market.

How to Properly Maintain and Clean a Simple Nitrogen Flushing Can Seamer Machine

Proper maintenance and cleaning of a simple nitrogen flushing can seamer machine are essential to ensure its optimal performance and longevity. Neglecting these tasks can lead to decreased efficiency, increased downtime, and potential safety hazards. In this article, we will discuss the importance of maintaining and cleaning a can seamer machine, as well as provide some tips on how to do so effectively.

Regular maintenance of a can seamer machine is crucial to prevent breakdowns and ensure smooth operation. One of the most important aspects of maintenance is lubrication. Proper lubrication of moving parts helps reduce friction, wear, and tear, extending the life of the machine. It is recommended to follow the manufacturer’s guidelines for the type and frequency of lubrication required for each part.

In addition to lubrication, regular inspection of the machine is also necessary. Check for any loose or damaged parts, leaks, or signs of wear. Addressing these issues promptly can prevent more significant problems down the line. It is also essential to keep the machine clean to prevent contamination of the product and maintain hygiene standards.

Cleaning a can seamer machine involves removing any debris, dust, or residue that may have accumulated during operation. Start by disconnecting the machine from the power source and allowing it to cool down. Use a soft brush or cloth to remove any visible dirt or debris from the exterior of the machine. Be sure to pay attention to hard-to-reach areas, such as crevices or corners, where dirt can accumulate.

Next, remove any removable parts, such as the lid, chuck, or rollers, and clean them thoroughly with a mild detergent and water. Avoid using harsh chemicals or abrasive cleaners, as they can damage the machine’s components. Rinse the parts thoroughly and allow them to dry completely before reassembling the machine.

Once the machine is clean, it is essential to perform a test run to ensure that everything is functioning correctly. Check for any unusual noises, vibrations, or leaks during operation. If you notice any issues, address them promptly to prevent further damage to the machine.

In addition to regular maintenance and cleaning, it is essential to follow proper operating procedures when using a can seamer machine. This includes using the correct settings for the type of can being sealed, ensuring that the can is properly aligned with the chuck, and monitoring the machine during operation for any signs of malfunction.

By following these tips for maintaining and cleaning a simple nitrogen flushing can seamer machine, you can ensure that it operates efficiently and safely for years to come. Proper maintenance not only extends the life of the machine but also helps prevent costly repairs and downtime. Remember to consult the manufacturer’s guidelines for specific maintenance instructions and schedule regular inspections to keep your machine in top condition.

Comparison of Different Models of Simple Nitrogen Flushing Can Seamer Machines

Nitrogen flushing can seamer machines are essential equipment in the food packaging industry. These machines help to maintain the freshness and quality of canned products by replacing the air inside the cans with nitrogen gas. This process helps to extend the shelf life of the products and prevent oxidation, which can lead to spoilage.

There are several models of nitrogen flushing can seamer machines available on the market, each with its own unique features and capabilities. In this article, we will compare different models of simple nitrogen flushing can seamer machines to help you make an informed decision when choosing the right machine for your packaging needs.

One popular model of a simple nitrogen flushing can seamer machine is the XYZ model. This machine is known for its compact size and user-friendly design, making it ideal for small to medium-sized food packaging operations. The XYZ model features a single head seamer and a nitrogen flushing system that can be easily adjusted to suit different can sizes.

Another model worth considering is the ABC model. This machine is designed for larger-scale food packaging operations and features multiple seaming heads for increased efficiency. The ABC model also comes with advanced nitrogen flushing technology that ensures a consistent and reliable gas flush for each can.

When comparing these two models, it is important to consider factors such as production capacity, ease of use, and maintenance requirements. The XYZ model may be more suitable for smaller operations with lower production volumes, while the ABC model is better suited for larger operations that require higher throughput.

In terms of production capacity, the ABC model outperforms the XYZ model due to its multiple seaming heads and faster processing speed. This makes the ABC model a better choice for high-volume production lines where efficiency is crucial.

Both models offer user-friendly interfaces and easy-to-use controls, but the XYZ model may be more suitable for operators with limited experience in using nitrogen flushing can seamer machines. The ABC model, on the other hand, may require more training and expertise to operate efficiently due to its advanced features and capabilities.

Maintenance requirements are also an important factor to consider when comparing these two models. The XYZ model is known for its low maintenance requirements and durable construction, making it a cost-effective option for small to medium-sized operations. The ABC model, while more complex, may require more frequent maintenance and servicing to ensure optimal performance.

In conclusion, when choosing a simple nitrogen flushing can seamer machine, it is important to consider factors such as production capacity, ease of use, and maintenance requirements. The XYZ model is a great option for smaller operations with lower production volumes, while the ABC model is better suited for larger operations with higher throughput. Ultimately, the right choice will depend on your specific packaging needs and budget constraints.