In the quest for sustainable packaging solutions, energy-efficient rotary granule machines are emerging as a vital component.

Energy-efficient rotary granule machines contribute to sustainability in several ways. Firstly, they consume less power during operation, reducing the overall energy footprint of the packaging process. This not only lowers electricity costs but also has a positive impact on the environment by minimizing greenhouse gas emissions associated with energy generation.

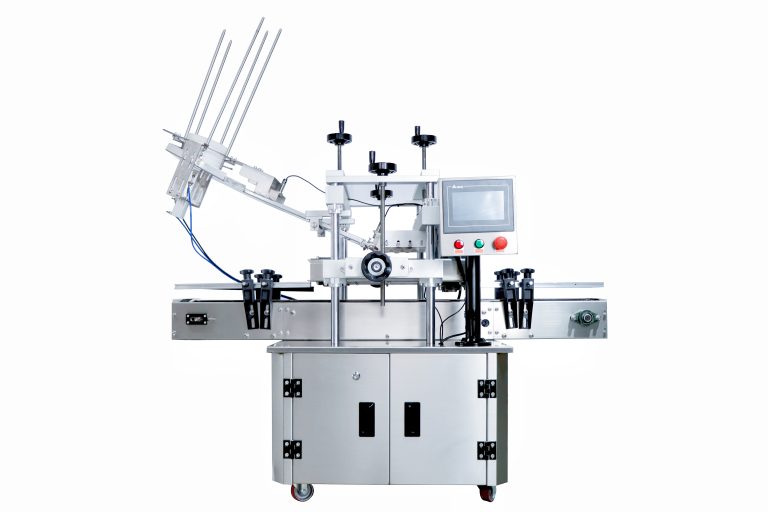

The design of these machines is optimized to minimize energy wastage. Advanced technologies such as variable speed drives and intelligent control systems ensure that the machine operates at the most energy-efficient levels based on the production requirements.

Moreover, the use of high-quality materials and components in their construction enhances their durability and longevity. This reduces the frequency of replacements and the associated manufacturing and disposal costs, further promoting sustainability.

-1024x683.jpg)

Energy-efficient rotary granule machines also support sustainable packaging by enabling precise filling, minimizing product waste and ensuring that the right amount of granules are packaged each time. This helps to reduce over-packaging and the use of unnecessary materials.

In addition, these machines often incorporate features that allow for easy integration with other sustainable packaging practices, such as the use of recyclable or biodegradable packaging materials.

By choosing energy-efficient rotary granule machines, businesses can align their packaging operations with sustainability goals, demonstrating their commitment to a greener future while also achieving operational efficiencies and cost savings.

In conclusion, energy-efficient rotary granule machines play a crucial role in driving sustainability within the packaging industry, offering a win-win solution for both the environment and businesses.