Benefits Of Using An Automatic Servo Double Head Pet Food Tinplate Can Closing Machine Factory

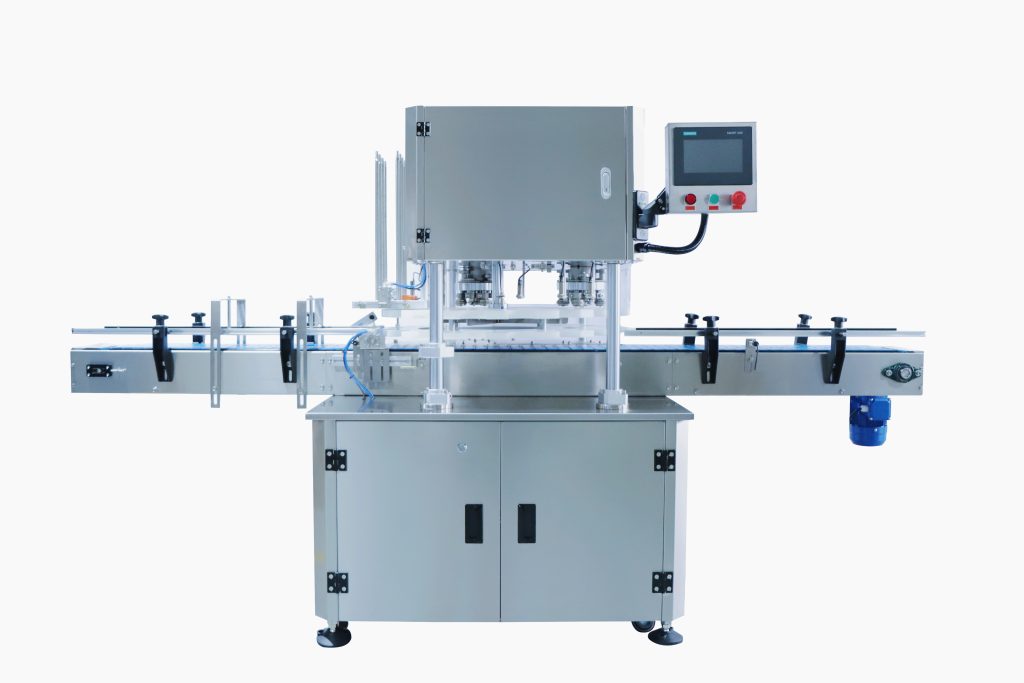

In the pet food industry, efficiency and precision are key factors in ensuring the quality and safety of products. One way to achieve this is by using an automatic servo double head pet food tinplate can closing machine factory. This advanced technology offers a range of benefits that can greatly improve the production process and overall quality of pet food products.

One of the main advantages of using an automatic servo double head pet food tinplate can closing machine factory is its ability to increase production speed. With its automated processes and high-speed capabilities, this machine can significantly reduce the time it takes to close tinplate cans, allowing for a faster and more efficient production line. This not only helps to meet the demands of a growing market but also ensures that pet food products are delivered to consumers in a timely manner.

Furthermore, the precision and accuracy of an automatic servo double head pet food tinplate can closing machine factory are unmatched. The servo-driven technology allows for precise control over the closing process, ensuring that each can is sealed correctly and securely. This level of accuracy is crucial in maintaining the freshness and quality of pet food products, as any errors in the closing process can lead to contamination or spoilage.

In addition to speed and precision, an automatic servo double head pet food tinplate can closing machine factory also offers versatility in its operation. With the ability to adjust settings and parameters, this machine can accommodate a wide range of can sizes and types, making it suitable for various pet food products. This flexibility allows manufacturers to easily switch between different packaging options without the need for extensive retooling or adjustments.

Another key benefit of using an automatic servo double head pet food tinplate can closing machine factory is its reliability and consistency. With its advanced technology and durable construction, this machine is designed to withstand the rigors of continuous operation, ensuring that it performs consistently and reliably day after day. This reliability is essential in maintaining a smooth production process and meeting the demands of a competitive market.

Furthermore, the automation provided by an automatic servo double head pet food tinplate can closing machine factory can help to reduce labor costs and improve overall efficiency. By eliminating the need for manual labor in the closing process, manufacturers can streamline their operations and allocate resources more effectively. This not only saves time and money but also allows employees to focus on other tasks that require human intervention.

Overall, the benefits of using an automatic servo double head pet food tinplate can closing machine factory are clear. From increased production speed and precision to versatility and reliability, this advanced technology offers a range of advantages that can greatly improve the efficiency and quality of pet food production. By investing in this innovative machine, manufacturers can stay ahead of the competition and deliver high-quality products to consumers with confidence.