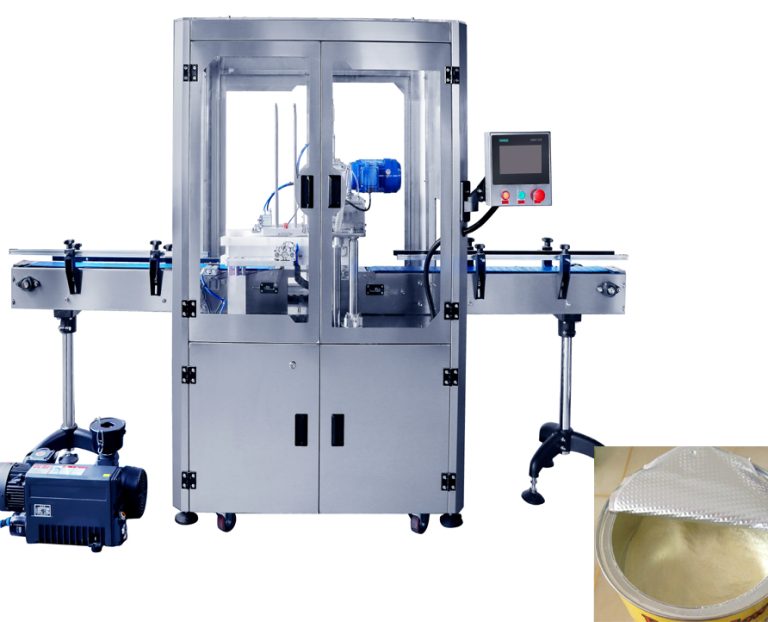

In the realm of pharmaceutical manufacturing, the fully automatic medicine liquid filling machine is a critical component that ensures accuracy, efficiency, and quality in the production process.

One of the primary advantages of this advanced machine is its remarkable precision. It is engineered to dispense the exact volume of medicine liquid with minimal deviation, which is of utmost importance in the pharmaceutical industry where dosage accuracy can have significant implications for patient health.

The speed and throughput of the fully automatic medicine liquid filling machine are also notable. It can handle a large number of containers in a short period, allowing for increased production capacity and meeting the high demand for medicines.

This machine is designed to maintain strict hygiene and sterility standards. It is constructed with materials that are easy to clean and disinfect, preventing any contamination of the medicine liquid and ensuring the safety and integrity of the final product.

The automation aspect not only reduces the potential for human error but also provides consistent and reliable performance. It operates smoothly, with advanced sensors and control systems that monitor the filling process in real-time and make immediate adjustments if necessary.

The flexibility of the machine allows it to handle different types and viscosities of medicine liquids, as well as various container sizes and shapes. This adaptability makes it suitable for a wide range of pharmaceutical products.

Maintenance of the fully automatic medicine liquid filling machine is straightforward, with accessible components and clear service protocols. Regular servicing and calibration ensure its continued accurate and efficient operation.

In summary, the fully automatic medicine liquid filling machine is a technological marvel that plays a vital role in the pharmaceutical supply chain. It guarantees the quality and consistency of medicine liquids, contributing to the well-being of patients and the success of pharmaceutical companies.

Stay updated with the latest in pharmaceutical manufacturing technology by following our blogs!