Table of Contents

Benefits of Fully Automatic Canned Food Tinplate Can Seaming Machines

Fully automatic canned food tinplate can seaming machines offer a myriad of benefits for food processing industries. These machines are designed to streamline the canning process, ensuring efficiency, consistency, and safety. From enhancing productivity to maintaining product integrity, the advantages of fully automatic can seaming machines are significant.

One of the primary benefits of fully automatic can seaming machines is their ability to improve production efficiency. These machines are equipped with advanced automation features that eliminate the need for manual labor, reducing the time and resources required for canning operations. By automating the seaming process, manufacturers can achieve higher throughput rates and meet increasing demand without compromising on quality.

Furthermore, fully automatic can seaming machines ensure consistency in the sealing process. Manual seaming can be prone to human error, leading to variations in seal quality and integrity. With automated machinery, every can undergoes the same precise sealing procedure, resulting in uniform seals that maintain product freshness and prevent contamination.

In addition to efficiency and consistency, fully automatic can seaming machines enhance product safety. Proper sealing is essential for preserving food quality and preventing bacterial contamination. These machines are equipped with advanced sealing mechanisms that create hermetic seals, effectively protecting the contents from external contaminants and extending shelf life.

Moreover, fully automatic can seaming machines offer versatility in can size and design. Whether it’s standard tinplate cans or customized containers, these machines can accommodate various shapes and sizes with minimal adjustment. This flexibility enables manufacturers to meet diverse customer demands and expand their product offerings without investing in multiple pieces of equipment.

Another significant advantage of fully automatic can seaming machines is their contribution to cost savings. While the initial investment may be higher compared to manual or semi-automatic machines, the long-term benefits outweigh the upfront costs. By reducing labor expenses, minimizing product wastage, and improving overall efficiency, these machines help companies optimize their production processes and maximize profitability.

Furthermore, fully automatic can seaming machines require minimal maintenance, leading to further cost savings over time. With regular upkeep and servicing, these machines can operate smoothly for extended periods, minimizing downtime and production interruptions. Additionally, their durable construction and robust design ensure reliability and longevity, providing a solid return on investment for manufacturers.

In conclusion, fully automatic canned food tinplate can seaming machines offer numerous benefits for food processing industries. From improving efficiency and consistency to enhancing product safety and versatility, these machines play a crucial role in modern canning operations. With their advanced automation features and cost-saving advantages, they are indispensable assets for manufacturers looking to streamline their production processes and maintain a competitive edge in the market.

How to Choose the Right Fully Automatic Canned Food Tinplate Can Seaming Machine

Fully automatic canned food tinplate can seaming machines have revolutionized the food packaging industry, offering efficiency, precision, and consistency in sealing canned goods. However, choosing the right machine for your production line requires careful consideration of various factors to ensure optimal performance and cost-effectiveness.

Firstly, it’s essential to assess your production needs and volume requirements. Determine the output capacity of the machine, considering factors such as the size of your operation, anticipated growth, and market demand. A machine with a higher sealing speed and larger can capacity may be necessary for high-volume production lines, while smaller operations may benefit from a more compact model.

Next, consider the types of cans your production line will be handling. Fully automatic can seaming machines are designed to accommodate various can sizes and shapes, including round, square, and rectangular cans. Ensure that the machine you choose is compatible with the specific dimensions and materials of your cans to avoid compatibility issues and downtime.

In addition to can size, consider the type of sealing method required for your products. Fully automatic can seaming machines offer different sealing options, including double seam, triple seam, and hermetic sealing, each suitable for different types of food products and packaging requirements. Evaluate the sealing capabilities of the machine and ensure it meets the quality and safety standards for your products.

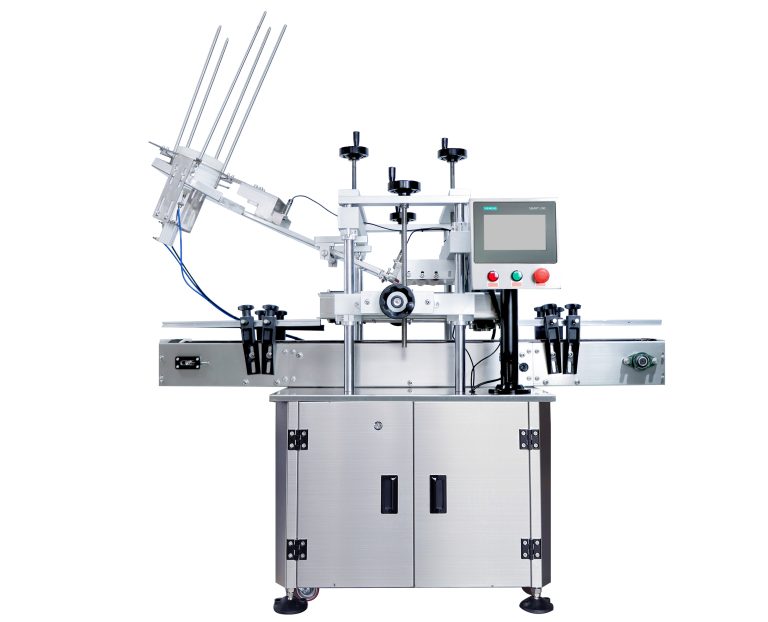

Furthermore, assess the overall construction and durability of the machine. Look for features such as stainless steel construction, robust sealing mechanisms, and easy-to-clean designs to ensure reliability and longevity in your production environment. A durable machine will minimize downtime and maintenance costs, maximizing your return on investment over time.

Another crucial factor to consider is automation and control features. Fully automatic can seaming machines come with a range of automation options, including PLC control systems, touchscreen interfaces, and remote monitoring capabilities. These features enhance efficiency, accuracy, and ease of operation, allowing for seamless integration into your production line and minimizing the need for manual intervention.

Moreover, consider the level of technical support and after-sales service provided by the manufacturer. Choose a reputable supplier with a track record of reliability and responsive customer support to ensure prompt assistance in case of technical issues or maintenance needs. Comprehensive training and documentation should also be provided to your operators to ensure proper use and maintenance of the machine.

Finally, evaluate the cost-effectiveness of the machine, considering factors such as initial investment, operating costs, and potential savings in labor and materials. While price is an important consideration, prioritize value and long-term performance to ensure a positive return on your investment.

In conclusion, selecting the right fully automatic canned food tinplate can seaming machine requires careful evaluation of production needs, can specifications, sealing methods, construction quality, automation features, technical support, and cost-effectiveness. By considering these factors and choosing a reputable supplier, you can optimize your packaging operations and ensure consistent quality and efficiency in sealing canned goods.