Table of Contents

Benefits of Using a Fully Automatic Double Head Tin Can Crimping Machine

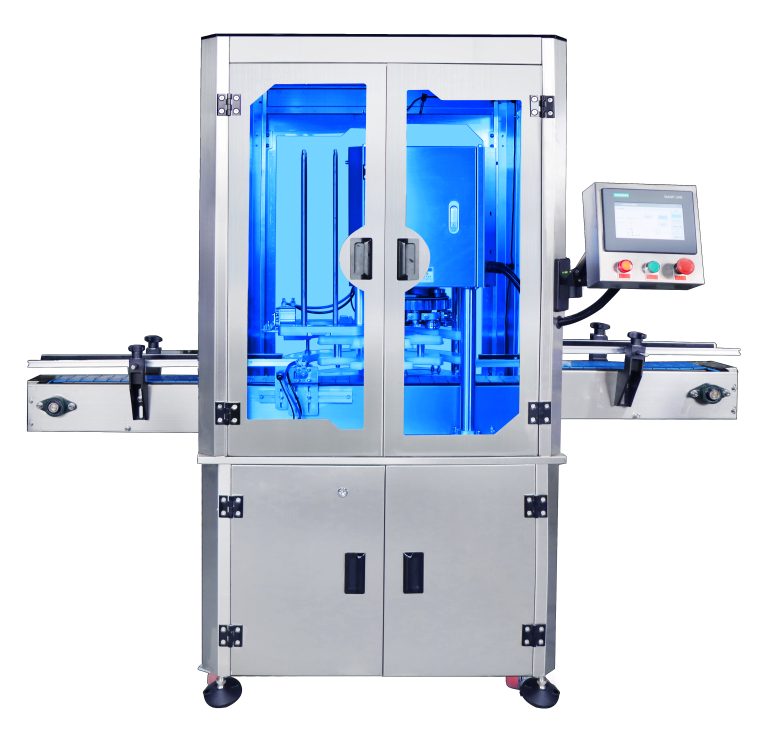

In the world of manufacturing, efficiency and precision are key factors in ensuring the success of a production line. One piece of equipment that can greatly enhance these aspects is a fully automatic double head tin can crimping machine. This machine is designed to crimp the lids onto tin cans with speed and accuracy, making it an essential tool for companies in the food and beverage industry, as well as other industries that rely on tin cans for packaging.

One of the main benefits of using a fully automatic double head tin can crimping machine is its ability to increase production output. With two crimping heads, this machine can crimp two cans simultaneously, effectively doubling the speed at which lids are applied to cans. This not only speeds up the production process but also allows for higher volumes of cans to be crimped in a shorter amount of time. This increased efficiency can lead to cost savings for companies, as they are able to produce more products in less time.

Another benefit of using a fully automatic double head tin can crimping machine is its precision and consistency. The machine is programmed to crimp the lids onto cans with a high level of accuracy, ensuring that each can is sealed properly. This eliminates the risk of human error and ensures that all cans are sealed correctly, reducing the likelihood of leaks or contamination. This level of precision is crucial in industries where product quality and safety are of utmost importance.

Furthermore, the fully automatic nature of this machine reduces the need for manual labor, freeing up workers to focus on other tasks within the production line. This not only increases overall efficiency but also improves worker safety by reducing the risk of repetitive strain injuries associated with manual crimping processes. Additionally, the machine is equipped with safety features to protect workers from potential hazards, further enhancing workplace safety.

In addition to its efficiency and precision, a fully automatic double head tin can crimping machine is also versatile and easy to use. The machine can be easily adjusted to accommodate different can sizes and lid types, making it suitable for a variety of packaging needs. Its user-friendly interface allows operators to quickly set up and operate the machine, reducing the need for extensive training or specialized skills. This versatility and ease of use make the machine a valuable asset for companies looking to streamline their production processes.

Overall, the benefits of using a fully automatic double head tin can crimping machine are clear. From increased production output and precision to improved worker safety and versatility, this machine offers a range of advantages for companies in need of efficient and reliable can sealing solutions. By investing in this technology, companies can enhance their production processes, reduce costs, and ensure the quality and safety of their products.

How to Choose the Right Fully Automatic Double Head Tin Can Crimping Machine for Your Business

In the world of manufacturing, efficiency and precision are key factors in ensuring the success of a business. When it comes to sealing tin cans, a fully automatic double head tin can crimping machine is a valuable piece of equipment that can streamline the production process and improve overall productivity. However, with so many options available on the market, choosing the right machine for your business can be a daunting task. In this article, we will discuss some important factors to consider when selecting a fully automatic double head tin can crimping machine.

First and foremost, it is essential to consider the size and capacity of the machine. The size of the machine should be compatible with the space available in your production facility. Additionally, the capacity of the machine should be able to meet the demands of your production line. It is important to choose a machine that can handle the volume of tin cans that your business produces on a daily basis.

Another important factor to consider is the speed and efficiency of the machine. A fully automatic double head tin can crimping machine should be able to crimp cans quickly and accurately to keep up with the pace of your production line. Look for a machine that offers high-speed crimping capabilities without compromising on the quality of the seal.

In addition to speed and capacity, it is crucial to consider the durability and reliability of the machine. A fully automatic double head tin can crimping machine is a significant investment for any business, so it is important to choose a machine that is built to last. Look for a machine that is made from high-quality materials and has a reputation for reliability. This will help minimize downtime and maintenance costs in the long run.

Furthermore, it is important to consider the versatility of the machine. A fully automatic double head tin can crimping machine that can accommodate a variety of can sizes and types will provide flexibility for your production line. Look for a machine that offers adjustable settings and can easily switch between different can sizes to meet the needs of your business.

When choosing a fully automatic double head tin can crimping machine, it is also important to consider the level of automation and control features. Look for a machine that offers user-friendly controls and automation features that can help streamline the production process and reduce the risk of human error. Additionally, consider whether the machine offers any advanced features such as automatic can feeding and rejection systems.

In conclusion, choosing the right fully automatic double head tin can crimping machine for your business is a crucial decision that can have a significant impact on your production efficiency and overall success. By considering factors such as size, capacity, speed, durability, versatility, and automation features, you can select a machine that meets the specific needs of your business. Investing in a high-quality machine will not only improve the efficiency of your production line but also help you stay competitive in the market.

Maintenance Tips for Ensuring Optimal Performance of Your Fully Automatic Double Head Tin Can Crimping Machine

Maintenance Tips for Ensuring Optimal Performance of Your Fully Automatic Double Head Tin Can Crimping Machine

In the world of manufacturing, efficiency and productivity are key factors in ensuring the success of a business. One piece of equipment that plays a crucial role in the production process is the fully automatic double head tin can crimping machine. This machine is designed to crimp the lids onto tin cans quickly and accurately, making it an essential tool for any company that produces canned goods. To ensure that your crimping machine operates at its best, regular maintenance is essential.

One of the most important maintenance tasks for your fully automatic double head tin can crimping machine is keeping it clean. Over time, dust, dirt, and debris can build up on the machine, causing it to operate less efficiently. Regularly cleaning the machine with a soft cloth and mild detergent can help prevent this buildup and keep your machine running smoothly.

In addition to keeping the machine clean, it is also important to regularly inspect the machine for any signs of wear or damage. Check the crimping heads, rollers, and other moving parts for any signs of wear, such as cracks or dents. If you notice any damage, it is important to replace the affected parts as soon as possible to prevent further damage to the machine.

Another important maintenance task for your fully automatic double head tin can crimping machine is lubrication. Proper lubrication of the moving parts of the machine is essential for smooth operation. Be sure to use the recommended lubricant for your machine and follow the manufacturer’s guidelines for how often to lubricate the machine.

In addition to regular cleaning, inspection, and lubrication, it is also important to calibrate your fully automatic double head tin can crimping machine regularly. Calibration ensures that the machine is crimping the lids onto the cans with the correct amount of pressure, ensuring a tight seal. If the machine is not calibrated correctly, it can lead to leaks and other issues with the finished product.

Regular maintenance of your fully automatic double head tin can crimping machine is essential for ensuring optimal performance and longevity. By following these maintenance tips, you can keep your machine running smoothly and efficiently, reducing downtime and increasing productivity. Remember to clean the machine regularly, inspect it for wear or damage, lubricate the moving parts, and calibrate the machine as needed.

In conclusion, proper maintenance of your fully automatic double head tin can crimping machine is essential for ensuring optimal performance and longevity. By following these maintenance tips, you can keep your machine running smoothly and efficiently, reducing downtime and increasing productivity. Remember to clean, inspect, lubricate, and calibrate your machine regularly to keep it in top condition. With proper maintenance, your fully automatic double head tin can crimping machine will continue to be a valuable asset to your manufacturing operation.