Table of Contents

Benefits of Fully Automatic Round Can Seaming Machines

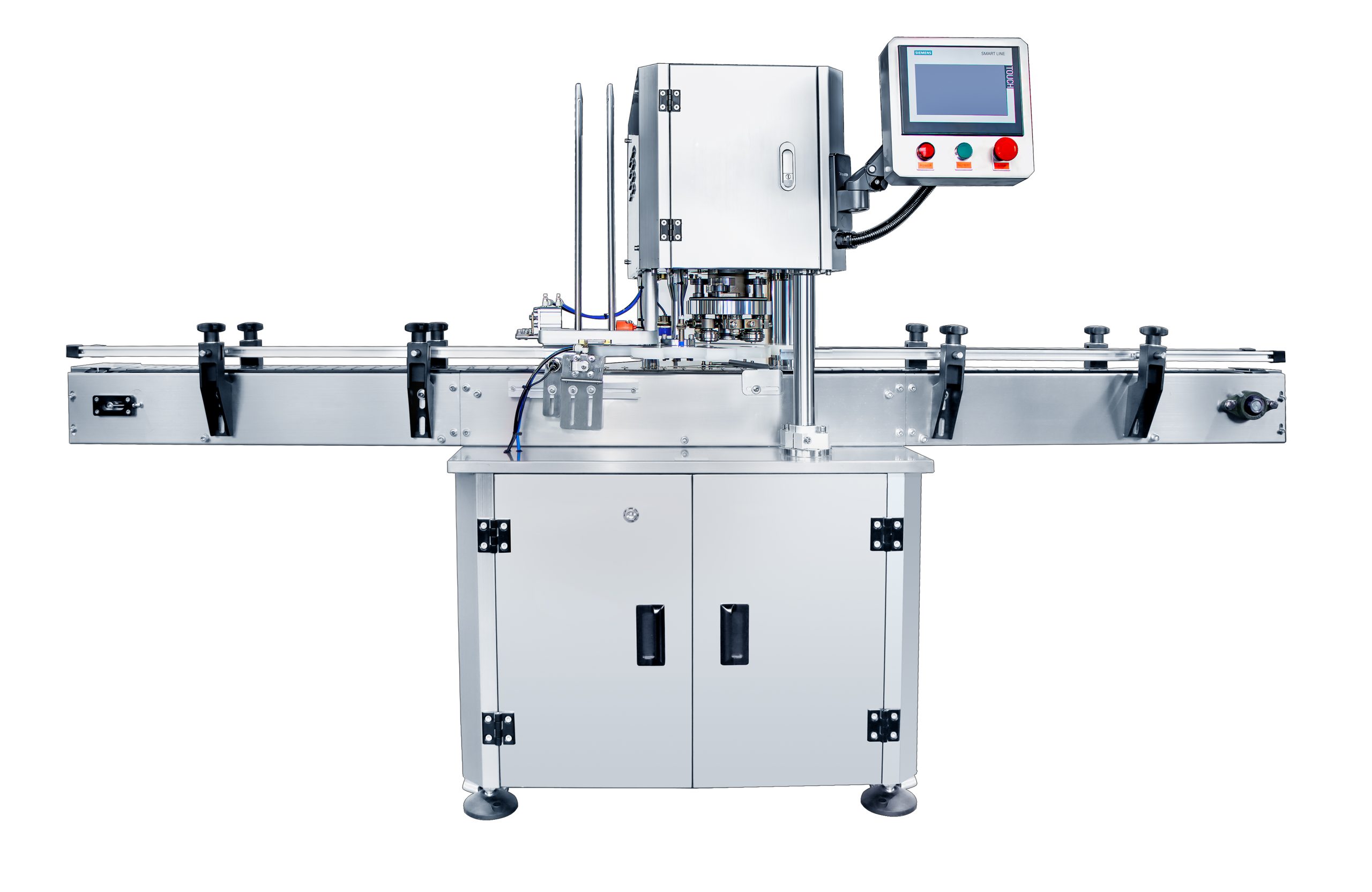

Fully automatic round can seaming machines have revolutionized the packaging industry by providing efficient and precise sealing of cans. These machines offer a wide range of benefits that make them a valuable investment for businesses looking to streamline their production processes and improve product quality.

One of the key benefits of fully automatic round can seaming machines is their ability to increase production efficiency. These machines are designed to seal cans at a much faster rate than manual sealing methods, allowing businesses to meet high production demands without compromising on quality. By automating the sealing process, these machines can significantly reduce the time and labor required to seal cans, resulting in increased productivity and cost savings for businesses.

In addition to improving production efficiency, fully automatic round can seaming machines also offer superior sealing quality. These machines are equipped with advanced technology that ensures a tight and secure seal on every can, preventing leaks and contamination. This level of precision and consistency is essential for businesses operating in industries where product integrity is paramount, such as food and beverage or pharmaceuticals.

Furthermore, fully automatic round can seaming machines are highly versatile and can accommodate a wide range of can sizes and materials. This flexibility allows businesses to easily switch between different can sizes and types without the need for extensive retooling or adjustments, saving time and reducing downtime. Additionally, these machines can be customized to meet specific production requirements, making them suitable for a variety of applications and industries.

Another significant benefit of fully automatic round can seaming machines is their user-friendly design. These machines are equipped with intuitive controls and interfaces that make them easy to operate and maintain. This user-friendly design reduces the need for extensive training and allows businesses to quickly integrate these machines into their production processes. Additionally, many fully automatic round can seaming machines are equipped with self-diagnostic features that help identify and resolve issues quickly, minimizing downtime and maximizing productivity.

Fully automatic round can seaming machines also offer a high level of reliability and durability. These machines are built to withstand the rigors of continuous use in industrial settings, ensuring consistent performance and longevity. By investing in a fully automatic round can seaming machine, businesses can minimize the risk of equipment failure and costly repairs, leading to increased operational efficiency and profitability.

In conclusion, fully automatic round can seaming machines offer a wide range of benefits that make them an essential tool for businesses looking to improve their production processes. From increased efficiency and superior sealing quality to versatility and user-friendly design, these machines provide businesses with a competitive edge in today’s fast-paced market. By investing in a fully automatic round can seaming machine, businesses can enhance their production capabilities, reduce costs, and deliver high-quality products to their customers.

Trends and Innovations in the Fully Automatic Round Can Seaming Machine Market

The fully automatic round can seaming machine market is experiencing significant growth and innovation as manufacturers strive to meet the increasing demand for efficient and reliable can sealing solutions. These machines are essential for sealing cans in various industries such as food and beverage, pharmaceuticals, and chemicals. The market is driven by factors such as the growing popularity of canned products, the need for improved packaging solutions, and the increasing focus on automation in manufacturing processes.

One of the key trends in the fully automatic round can seaming machine market is the integration of advanced technologies such as robotics and artificial intelligence. Manufacturers are incorporating these technologies into their machines to improve efficiency, accuracy, and speed. For example, some machines are equipped with sensors and cameras that can detect defects in cans and automatically adjust the seaming process to ensure a perfect seal. This level of automation not only improves the quality of the sealed cans but also reduces the need for manual intervention, leading to higher productivity and cost savings for manufacturers.

Another trend in the market is the development of machines that can handle a wide range of can sizes and materials. As the demand for canned products continues to grow, manufacturers need machines that can accommodate different can sizes and materials to meet the diverse needs of their customers. Fully automatic round can seaming machines are now available in various configurations, with adjustable settings that allow them to seal cans of different diameters and heights. Some machines are also capable of sealing cans made of different materials such as aluminum, tinplate, and plastic, providing manufacturers with greater flexibility in their production processes.

In addition to technological advancements, manufacturers are also focusing on improving the sustainability and eco-friendliness of their machines. Many fully automatic round can seaming machines now come with energy-efficient features that help reduce power consumption and carbon emissions. Some machines are also designed to minimize waste by using recyclable materials and optimizing the use of resources. By incorporating sustainable practices into their machines, manufacturers are not only reducing their environmental impact but also appealing to environmentally conscious consumers who are increasingly seeking products that are produced in an eco-friendly manner.

Furthermore, the fully automatic round can seaming machine market is witnessing a trend towards customization and personalization. Manufacturers are offering machines that can be tailored to meet the specific requirements of individual customers, such as customizing the seaming process, adding additional features, or integrating with other equipment in the production line. This level of customization allows manufacturers to optimize their production processes and achieve higher levels of efficiency and quality in their canned products.

Overall, the fully automatic round can seaming machine market is evolving rapidly to meet the changing needs of manufacturers in various industries. With advancements in technology, sustainability, and customization, these machines are becoming essential tools for sealing cans efficiently and reliably. As the demand for canned products continues to grow, manufacturers will need to invest in innovative seaming solutions to stay competitive in the market. By embracing these trends and innovations, manufacturers can improve their production processes, reduce costs, and deliver high-quality canned products to consumers around the world.

Future Growth Opportunities for Fully Automatic Round Can Seaming Machines

Fully automatic round can seaming machines have become an essential piece of equipment in the packaging industry. These machines are designed to seal cans quickly and efficiently, ensuring that the contents remain fresh and secure. As the demand for canned goods continues to rise, the market for fully automatic round can seaming machines is expected to experience significant growth in the coming years.

One of the key drivers of this growth is the increasing popularity of canned beverages. With consumers becoming more health-conscious and environmentally aware, many are turning to canned options as a more sustainable and convenient choice. This trend has led to a surge in demand for fully automatic round can seaming machines, as manufacturers seek to meet the needs of this expanding market.

In addition to beverages, the food industry is also driving the growth of the fully automatic round can seaming machine market. Canned foods have long been a staple in households around the world, offering convenience and long shelf life. As consumers continue to seek out quick and easy meal options, the demand for canned goods is expected to remain strong, further fueling the need for efficient can sealing equipment.

Another factor contributing to the growth of the fully automatic round can seaming machine market is the increasing focus on food safety and quality. Sealing cans properly is essential to prevent contamination and ensure that products remain fresh and safe for consumption. Fully automatic round can seaming machines offer a high level of precision and consistency, helping manufacturers meet strict quality standards and regulations.

As the market for fully automatic round can seaming machines continues to expand, manufacturers are investing in research and development to improve the efficiency and capabilities of these machines. New technologies are being introduced to enhance sealing speed, accuracy, and reliability, allowing manufacturers to increase production capacity and meet growing demand.

Furthermore, advancements in automation and digitalization are transforming the way fully automatic round can seaming machines operate. Integrated sensors and control systems are being implemented to monitor and adjust the sealing process in real-time, reducing the risk of errors and downtime. These innovations are not only improving efficiency but also reducing operating costs for manufacturers.

Looking ahead, the future growth opportunities for fully automatic round can seaming machines are promising. With the increasing demand for canned goods across various industries, manufacturers are expected to continue investing in advanced sealing equipment to meet consumer needs and stay competitive in the market. Additionally, as technology continues to evolve, we can expect to see further improvements in the performance and capabilities of fully automatic round can seaming machines.

In conclusion, the fully automatic round can seaming machine market is poised for significant growth in the coming years, driven by the rising demand for canned beverages and foods, as well as the focus on food safety and quality. With ongoing advancements in technology and automation, manufacturers are well-positioned to capitalize on these opportunities and meet the evolving needs of the packaging industry.