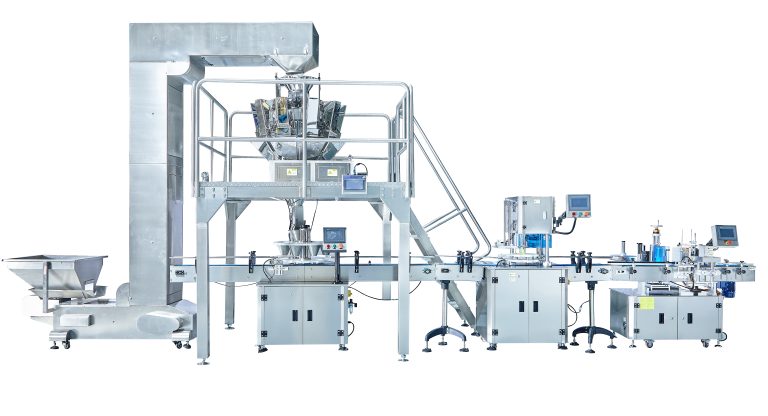

In the world of canned food production, the vacuum canned food tin can seamer machine plays a crucial role. This advanced piece of equipment is dedicated to ensuring the perfect sealing of tin cans, preserving the quality and freshness of the contents within.

One of the primary benefits of this machine is its vacuum sealing capability. By creating a vacuum inside the can before sealing, it effectively removes oxygen and other gases that can cause spoilage and degradation of the food. This extends the shelf life of canned foods and maintains their nutritional value and flavor.

The seaming process is highly precise and reliable. The machine ensures a tight and leak-proof seal, preventing any contaminants from entering the can and protecting the food from external factors. This level of sealing integrity gives consumers confidence in the safety and quality of the canned products.

The machine is designed to handle a high production volume, allowing manufacturers to meet the demands of the market efficiently. Its speed and consistency in seaming contribute to a smooth and productive manufacturing line.

The adjustability of the vacuum canned food tin can seamer machine is another notable feature. It can be configured to accommodate different tin can sizes and shapes, providing flexibility for producers who may have a diverse range of products.

Maintenance of the machine is relatively straightforward, with accessible components and clear maintenance guidelines. Regular servicing and upkeep ensure its continued optimal performance and longevity.

In conclusion, the vacuum canned food tin can seamer machine is an essential tool in the canned food industry. It guarantees that canned foods reach consumers in the best possible condition, maintaining their quality and appeal.

Stay tuned to our blogs for more detailed insights and updates on the latest developments in food packaging machinery!