Table of Contents

Benefits of Using an Automatic Beverage Soda Cola Drink Can Closer Machine

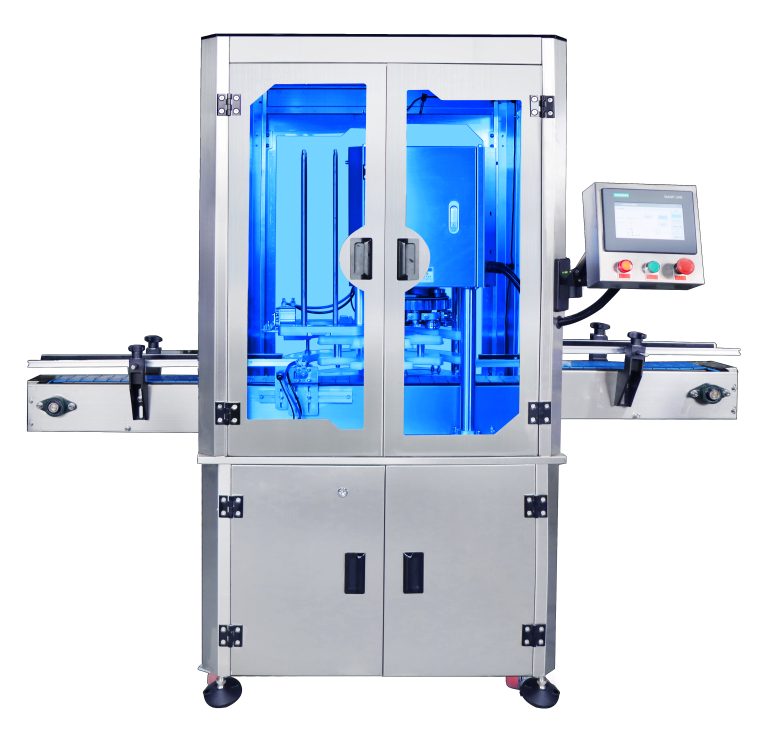

An automatic beverage soda cola drink can closer machine is a valuable piece of equipment for businesses in the beverage industry. This machine is designed to efficiently seal aluminum cans filled with carbonated beverages, ensuring that the product remains fresh and carbonated for an extended period of time. There are several benefits to using an automatic can closer machine, which we will explore in this article.

One of the primary benefits of using an automatic can closer machine is increased efficiency. Manual can closing can be a time-consuming and labor-intensive process, especially for businesses that produce large quantities of canned beverages. By automating the can closing process, businesses can significantly increase their production output and reduce the amount of time and labor required to seal cans. This can lead to cost savings and improved overall efficiency in the production process.

In addition to increased efficiency, automatic can closer machines also offer improved consistency and accuracy in the sealing process. Manual can closing can be prone to human error, resulting in improperly sealed cans that may leak or lose carbonation over time. Automatic can closer machines are designed to seal cans with precision and consistency, ensuring that each can is properly sealed and ready for distribution. This can help businesses maintain a high level of product quality and customer satisfaction.

Another benefit of using an automatic can closer machine is improved product safety and hygiene. Manual can closing can expose the product to potential contaminants, such as dirt, dust, or bacteria, which can compromise the quality and safety of the beverage. Automatic can closer machines are designed to seal cans in a controlled and sterile environment, minimizing the risk of contamination and ensuring that the product remains safe for consumption. This can help businesses comply with food safety regulations and maintain a high standard of product quality.

Furthermore, automatic can closer machines are designed to be user-friendly and easy to operate. Most machines are equipped with intuitive controls and settings that allow operators to quickly and easily adjust the machine to accommodate different can sizes and sealing requirements. This can help businesses streamline their production process and reduce the amount of training and supervision required to operate the machine effectively.

Overall, the benefits of using an automatic can closer machine are numerous and can have a significant impact on the efficiency, consistency, and quality of beverage production. By automating the can closing process, businesses can increase their production output, improve product safety and hygiene, and reduce the risk of human error. Additionally, automatic can closer machines are user-friendly and easy to operate, making them a valuable investment for businesses in the beverage industry.

How to Choose the Right Automatic Beverage Soda Cola Drink Can Closer Machine for Your Business

In the beverage industry, efficiency and consistency are key factors in ensuring the success of your business. One way to achieve this is by investing in an automatic beverage soda cola drink can closer machine. These machines are designed to streamline the can closing process, saving time and labor costs while also ensuring a tight seal on each can.

When choosing the right automatic beverage soda cola drink can closer machine for your business, there are several factors to consider. The first thing to think about is the size and capacity of the machine. Depending on the volume of cans you need to close, you will want to choose a machine that can handle your production needs. Some machines are designed for smaller operations, while others are built for high-volume production.

Another important factor to consider is the speed of the machine. If you have a high-volume production line, you will want a machine that can close cans quickly and efficiently. Look for a machine that offers adjustable speeds so you can customize the closing process to meet your specific needs.

In addition to size and speed, you will also want to consider the durability and reliability of the machine. Look for a machine that is built to last and can withstand the demands of a busy production environment. Check for features like stainless steel construction and high-quality components that will ensure the longevity of the machine.

When it comes to choosing the right automatic beverage soda cola drink can closer machine, it is also important to consider the ease of use and maintenance. Look for a machine that is user-friendly and easy to operate, with clear instructions and intuitive controls. You will also want to choose a machine that is easy to clean and maintain, to ensure that it continues to operate at peak performance.

Finally, consider the cost of the machine and the return on investment it will provide for your business. While it may be tempting to choose the cheapest option, it is important to weigh the upfront cost against the long-term benefits of increased efficiency and productivity. Look for a machine that offers a good balance of quality and affordability, and that will provide a solid return on investment for your business.

In conclusion, choosing the right automatic beverage soda cola drink can closer machine for your business is an important decision that can have a significant impact on your production process. Consider factors like size, speed, durability, ease of use, and cost when making your decision. By investing in a high-quality machine that meets your specific needs, you can streamline your production process, save time and labor costs, and ensure the success of your business in the competitive beverage industry.

Maintenance Tips for Ensuring the Longevity of Your Automatic Beverage Soda Cola Drink Can Closer Machine

Automatic beverage soda cola drink can closer machines are essential equipment for businesses in the beverage industry. These machines help streamline the packaging process by sealing cans of soda or cola efficiently and effectively. To ensure the longevity of your automatic beverage soda cola drink can closer machine, it is crucial to follow proper maintenance tips. By taking care of your machine, you can extend its lifespan and avoid costly repairs or replacements.

One of the most important maintenance tips for your automatic beverage soda cola drink can closer machine is to regularly clean and sanitize it. Over time, residue from soda or cola can build up on the machine’s components, leading to malfunctions and decreased efficiency. To prevent this, it is recommended to clean the machine after each use. Use a mild detergent and warm water to clean the surfaces of the machine, paying special attention to areas where residue may accumulate. Additionally, sanitize the machine regularly to prevent bacterial growth and ensure the safety of your products.

In addition to cleaning and sanitizing, it is essential to inspect the machine regularly for any signs of wear and tear. Check for loose or damaged parts, such as seals, gaskets, or belts, and replace them as needed. Regular inspections can help identify potential issues before they escalate into major problems, saving you time and money in the long run. It is also important to lubricate moving parts of the machine to reduce friction and prevent premature wear. Use a food-grade lubricant recommended by the manufacturer to ensure the machine operates smoothly and efficiently.

Another maintenance tip for ensuring the longevity of your automatic beverage soda cola drink can closer machine is to calibrate it regularly. Calibration ensures that the machine seals cans at the correct pressure and temperature, resulting in a tight and secure seal. Improper calibration can lead to leaks or incomplete seals, compromising the quality of your products. Follow the manufacturer’s guidelines for calibration and make adjustments as needed to maintain optimal performance.

Furthermore, it is crucial to train your staff on proper operating procedures for the automatic beverage soda cola drink can closer machine. Improper use of the machine can cause damage and reduce its lifespan. Provide training on how to operate the machine safely and efficiently, including loading cans, adjusting settings, and troubleshooting common issues. Encourage your staff to report any problems or concerns with the machine promptly, so they can be addressed before they escalate.

In conclusion, proper maintenance is essential for ensuring the longevity of your automatic beverage soda cola drink can closer machine. By following these maintenance tips, you can keep your machine in top condition and avoid costly repairs or replacements. Regular cleaning, inspection, lubrication, calibration, and staff training are key components of a comprehensive maintenance plan. By investing time and effort into maintaining your machine, you can maximize its lifespan and continue to produce high-quality products for your customers.