Table of Contents

Benefits of Using a Beverage Double Head Servo Can Closing Machine

In the beverage industry, efficiency and precision are key factors in ensuring the quality and consistency of the final product. One important aspect of the production process is the sealing of cans, which plays a crucial role in maintaining the freshness and integrity of the beverage inside. To achieve this, many manufacturers are turning to advanced technology such as the beverage double head servo can closing machine.

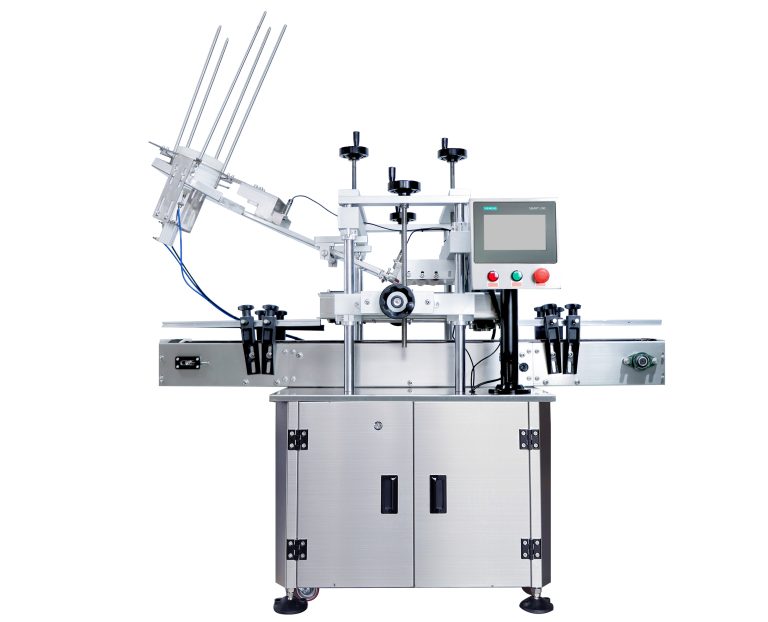

This innovative machine is designed to streamline the can closing process by utilizing servo motors to control the movement of the closing heads. This results in a more precise and efficient operation, reducing the risk of errors and ensuring a tight seal on every can. The use of servo motors also allows for greater flexibility in adjusting the speed and pressure of the closing heads, making it easier to accommodate different can sizes and materials.

One of the key benefits of using a beverage double head servo can closing machine is its ability to increase production output. By automating the can closing process and minimizing the need for manual intervention, manufacturers can significantly reduce the time and labor required to seal each can. This not only improves overall efficiency but also allows for higher production volumes to meet growing demand.

In addition to improving efficiency, the use of a double head servo can closing machine can also enhance the quality of the final product. The precise control offered by servo motors ensures a consistent and secure seal on every can, reducing the risk of leaks or contamination. This is especially important in the beverage industry, where product quality and safety are top priorities.

Furthermore, the advanced technology used in these machines can help to minimize waste and reduce costs. By optimizing the sealing process and minimizing errors, manufacturers can avoid the need to discard improperly sealed cans, saving both time and resources. This can have a significant impact on the bottom line, allowing companies to operate more efficiently and competitively in the market.

Another advantage of using a beverage double head servo can closing machine is its versatility. These machines are designed to handle a wide range of can sizes and materials, making them suitable for use in various beverage production settings. Whether sealing standard aluminum cans or specialty containers, manufacturers can rely on these machines to deliver consistent results every time.

Overall, the benefits of using a beverage double head servo can closing machine are clear. From improving efficiency and quality to reducing waste and costs, these machines offer a range of advantages that can help manufacturers stay competitive in the fast-paced beverage industry. By investing in this advanced technology, companies can streamline their production process, enhance product quality, and ultimately drive success in the market.

How to Choose the Right Beverage Double Head Servo Can Closing Machine for Your Production Line

When it comes to choosing the right equipment for your production line, there are many factors to consider. One important piece of machinery that can make a big difference in the efficiency and quality of your operation is the beverage double head servo can closing machine. This machine is designed to seal cans quickly and accurately, ensuring that your products are properly sealed and ready for distribution.

One of the key factors to consider when choosing a beverage double head servo can closing machine is the speed at which it can operate. The faster the machine can seal cans, the more efficiently your production line will run. Look for a machine that can handle a high volume of cans per minute to keep up with the demands of your operation.

In addition to speed, it’s important to consider the accuracy of the machine. A double head servo can closing machine should be able to seal cans consistently and securely, without any leaks or defects. Look for a machine that has a reputation for producing high-quality seals to ensure that your products are properly protected.

Another important factor to consider when choosing a beverage double head servo can closing machine is the ease of use. The machine should be easy to set up and operate, with intuitive controls that make it simple for your employees to use. Look for a machine that comes with clear instructions and training materials to help your team get up to speed quickly.

Durability is also an important consideration when choosing a beverage double head servo can closing machine. The machine should be built to last, with a sturdy construction that can withstand the rigors of a busy production line. Look for a machine that is made from high-quality materials and has a reputation for reliability to ensure that it will continue to perform well for years to come.

When choosing a beverage double head servo can closing machine, it’s also important to consider the size and layout of your production line. Make sure that the machine will fit comfortably into your existing space and that it can be easily integrated into your workflow. Consider whether you need a standalone machine or one that can be integrated into a larger production line for maximum efficiency.

Finally, consider the cost of the machine when making your decision. While it’s important to invest in a high-quality machine that will meet your production needs, you also need to consider your budget. Look for a machine that offers good value for money, with a balance of quality and affordability that fits within your financial constraints.

In conclusion, choosing the right beverage double head servo can closing machine is an important decision that can have a big impact on the efficiency and quality of your production line. Consider factors such as speed, accuracy, ease of use, durability, size, and cost when making your decision. By taking the time to research your options and choose a machine that meets your specific needs, you can ensure that your production line runs smoothly and efficiently, producing high-quality products that meet the needs of your customers.

Maintenance Tips for Ensuring Optimal Performance of Your Beverage Double Head Servo Can Closing Machine

When it comes to running a successful beverage production line, having a reliable can closing machine is essential. The beverage double head servo can closing machine is a popular choice for many manufacturers due to its efficiency and precision. However, like any piece of equipment, regular maintenance is crucial to ensure optimal performance and longevity.

One of the most important maintenance tasks for your beverage double head servo can closing machine is regular cleaning. Over time, dust, debris, and residue from the cans can build up on the machine, leading to decreased performance and potential malfunctions. It is recommended to clean the machine after each production run to prevent any buildup. Use a soft cloth and a mild detergent to wipe down the machine, paying special attention to the sealing surfaces and moving parts.

In addition to regular cleaning, it is important to inspect the machine for any signs of wear or damage. Check the seals, gaskets, and O-rings for any cracks or tears, as these can lead to leaks and decreased efficiency. Inspect the moving parts for any signs of wear, such as loose screws or misaligned components. If you notice any issues, it is important to address them promptly to prevent further damage to the machine.

Another important maintenance task for your beverage double head servo can closing machine is lubrication. Proper lubrication of the moving parts is essential to ensure smooth operation and prevent premature wear. Use a high-quality lubricant recommended by the manufacturer and apply it to the designated areas according to the machine’s manual. Be sure to follow the recommended schedule for lubrication to keep the machine running smoothly.

In addition to regular cleaning, inspection, and lubrication, it is important to calibrate the machine periodically to ensure accurate can closing. Over time, the machine may become misaligned or lose calibration, leading to improper sealing of the cans. Follow the manufacturer’s guidelines for calibration and perform this task regularly to maintain optimal performance.

Finally, it is important to train your staff on proper operation and maintenance of the beverage double head servo can closing machine. Ensure that all operators are familiar with the machine’s manual and understand the importance of regular maintenance tasks. Encourage them to report any issues or concerns with the machine promptly to prevent further damage.

In conclusion, proper maintenance is essential for ensuring optimal performance of your beverage double head servo can closing machine. Regular cleaning, inspection, lubrication, calibration, and staff training are all important aspects of maintaining the machine. By following these maintenance tips, you can extend the life of your machine and ensure smooth operation of your beverage production line.