Table of Contents

Benefits of Using Canned Food Tin Can Chamber Vacuum Seamer

Canned food has been a staple in households for decades, providing a convenient and long-lasting option for preserving food. One crucial component of the canning process is sealing the cans to ensure the contents remain fresh and free from contamination. This is where a tin can chamber vacuum seamer comes into play, offering a reliable and efficient way to seal canned food products.

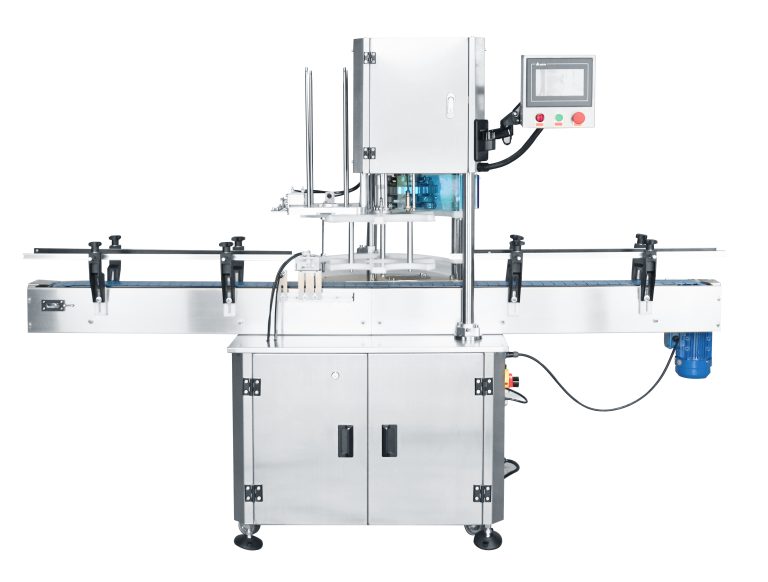

One of the primary benefits of using a canned food tin can chamber vacuum seamer is its ability to create a tight and secure seal on the cans. This is essential for maintaining the quality and freshness of the food inside, as a proper seal prevents air and moisture from entering the can and causing spoilage. The vacuum seamer uses a combination of pressure and heat to seal the cans, ensuring that the contents are protected from external elements.

In addition to preserving the quality of the food, a tin can chamber vacuum seamer also helps to extend the shelf life of canned products. By creating a tight seal that prevents air and moisture from entering the can, the seamer helps to slow down the process of oxidation and microbial growth, which can lead to spoilage. This means that canned food products sealed with a vacuum seamer can last longer on the shelf, reducing waste and saving money for both manufacturers and consumers.

Another benefit of using a canned food tin can chamber vacuum seamer is its efficiency and speed. These machines are designed to seal cans quickly and accurately, allowing manufacturers to process large quantities of canned food products in a relatively short amount of time. This can help to increase productivity and reduce production costs, making the seamer a valuable investment for food processing facilities.

Furthermore, a tin can chamber vacuum seamer offers a high level of precision and consistency in sealing cans. The machine is equipped with sensors and controls that ensure each can is sealed to the correct specifications, reducing the risk of leaks or other issues that can compromise the quality of the product. This level of precision is essential for maintaining the integrity of the canned food and ensuring that it meets safety and quality standards.

Overall, the benefits of using a canned food tin can chamber vacuum seamer are clear. From preserving the quality and freshness of the food to extending its shelf life and increasing production efficiency, these machines offer a range of advantages for food manufacturers. By investing in a vacuum seamer, companies can ensure that their canned food products are sealed securely and reliably, providing consumers with safe and high-quality products that they can trust.

How to Choose the Right Canned Food Tin Can Chamber Vacuum Seamer

Canned food has been a staple in households for decades, providing convenience and long shelf life for a variety of food items. One crucial component of the canning process is the seamer, which seals the cans to ensure the contents remain fresh and safe for consumption. When it comes to choosing the right canned food tin can chamber vacuum seamer, there are several factors to consider to ensure you select the best option for your needs.

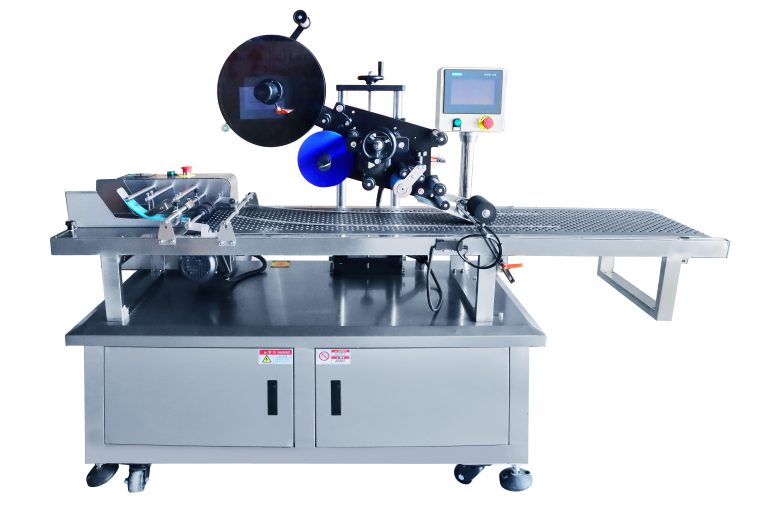

One of the first things to consider when choosing a canned food tin can chamber vacuum seamer is the size and capacity of the machine. Depending on the volume of cans you need to seal, you will want to select a seamer that can handle the workload efficiently. It is essential to consider not only the current needs of your operation but also any potential growth in production volume in the future.

Another important factor to consider is the speed and efficiency of the seamer. A faster seamer can help increase productivity and reduce downtime, ultimately saving you time and money in the long run. Look for a seamer that can consistently seal cans at a high rate without compromising on the quality of the seal.

The quality of the seal is crucial when it comes to canned food, as a poor seal can lead to contamination and spoilage of the contents. Look for a seamer that can create a strong, airtight seal that will keep your canned food fresh for an extended period. Some seamers offer additional features such as double seam inspection systems to ensure the quality of the seal meets industry standards.

When choosing a canned food tin can chamber vacuum seamer, it is also essential to consider the maintenance and upkeep of the machine. Look for a seamer that is easy to clean and maintain, with accessible parts that can be replaced or repaired quickly. Regular maintenance is crucial to ensure the seamer operates efficiently and prolong its lifespan.

Cost is another factor to consider when choosing a canned food tin can chamber vacuum seamer. While it may be tempting to opt for a cheaper option, it is essential to consider the long-term costs associated with maintenance, repairs, and downtime. Investing in a high-quality seamer from a reputable manufacturer may cost more upfront but can save you money in the long run by reducing maintenance and repair costs.

In conclusion, choosing the right canned food tin can chamber vacuum seamer is essential to ensure the quality and safety of your canned food products. Consider factors such as size, capacity, speed, seal quality, maintenance, and cost when selecting a seamer for your operation. By carefully evaluating these factors and choosing a seamer that meets your specific needs, you can ensure that your canned food products are sealed efficiently and effectively, keeping them fresh and safe for consumption.

Maintenance Tips for Canned Food Tin Can Chamber Vacuum Seamer

Canned food tin can chamber vacuum seamers are essential equipment in the food packaging industry. They play a crucial role in sealing cans to ensure the freshness and safety of the food products inside. To maintain the efficiency and longevity of your seamer, it is important to follow proper maintenance practices. In this article, we will discuss some key maintenance tips for canned food tin can chamber vacuum seamers.

Regular cleaning is essential to keep your seamer in optimal condition. Make sure to clean the seamer after each use to remove any food residue or debris that may have accumulated. Use a mild detergent and warm water to clean the exterior and interior of the seamer. Pay special attention to the sealing components and make sure they are free from any buildup that could affect the quality of the seal.

Inspect the seamer regularly for any signs of wear and tear. Check the sealing components, such as the chuck and seaming rolls, for any damage or deformation. Replace any worn or damaged parts immediately to prevent any issues with the sealing process. It is also important to check the alignment of the seamer to ensure that it is properly sealing the cans. Misalignment can lead to leaks and compromised food safety.

Lubrication is another important aspect of seamer maintenance. Make sure to lubricate the moving parts of the seamer regularly to reduce friction and wear. Use a food-grade lubricant that is compatible with the materials used in the seamer. Over-lubrication should be avoided as it can attract dust and debris, leading to potential issues with the sealing process.

Calibration is crucial for ensuring the accuracy of the seamer. Regularly calibrate the seamer to ensure that it is sealing the cans at the correct pressure and temperature. Improper calibration can result in under or over-sealing, which can compromise the quality and safety of the food products. Consult the manufacturer’s guidelines for the recommended calibration procedures and frequency.

In addition to regular maintenance, it is important to train your staff on proper operating procedures for the seamer. Make sure that all operators are familiar with the equipment and know how to use it safely and effectively. Provide ongoing training to keep your staff up to date on best practices and troubleshooting techniques.

In conclusion, proper maintenance is essential for keeping your canned food tin can chamber vacuum seamer in optimal condition. Regular cleaning, inspection, lubrication, calibration, and staff training are key components of a successful maintenance program. By following these tips, you can ensure that your seamer operates efficiently and effectively, providing safe and high-quality sealed cans for your food products. Remember that a well-maintained seamer not only improves the quality of your products but also extends the lifespan of your equipment, ultimately saving you time and money in the long run.