Benefits of Using a Fully Auto Metal Can Filling Machine for Sauce

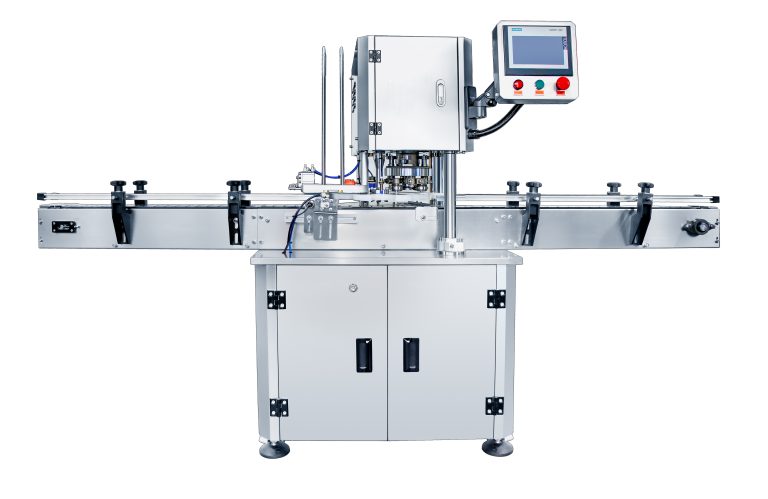

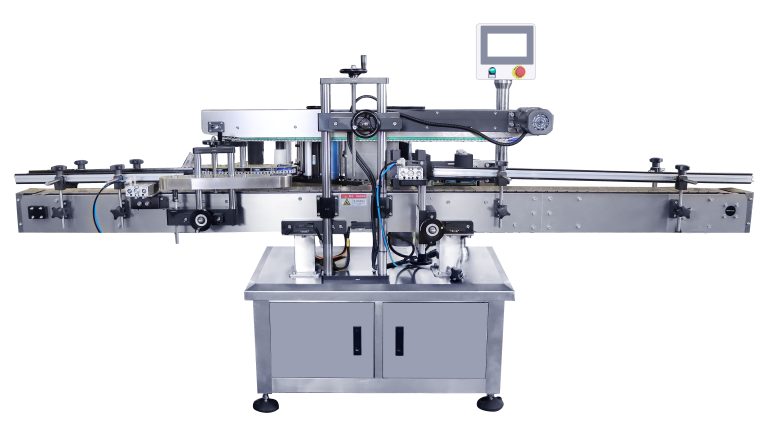

In the food industry, efficiency and precision are key factors in ensuring the quality and consistency of products. When it comes to filling metal cans with sauce, using a fully automatic metal can filling machine can offer numerous benefits. These machines are designed to streamline the filling process, increase productivity, and reduce the risk of contamination. In this article, we will explore the advantages of using a fully auto metal can filling machine for sauce production.

One of the primary benefits of using a fully automatic metal can filling machine is its ability to fill cans quickly and accurately. These machines are equipped with advanced technology that allows them to fill cans with sauce at a consistent rate, ensuring that each can is filled to the correct level. This level of precision is essential for maintaining the quality and consistency of the product, as even small variations in filling levels can affect the taste and appearance of the sauce.

Additionally, fully automatic metal can filling machines are designed to operate at high speeds, allowing for increased production output. This can be particularly beneficial for food manufacturers who need to fill a large number of cans in a short amount of time. By automating the filling process, these machines can help companies meet demand and increase their overall efficiency.

Another advantage of using a fully auto metal can filling machine is the reduced risk of contamination. Manual filling processes can be prone to errors and inconsistencies, which can lead to contamination issues. By using a fully automatic machine, companies can minimize the risk of contamination and ensure that their products meet strict quality and safety standards.

Furthermore, fully automatic metal can filling machines are easy to operate and require minimal supervision. Once the machine is set up and calibrated, it can run continuously without the need for constant monitoring. This can help companies save time and resources, as they can focus on other aspects of production while the machine handles the filling process.

In addition to these benefits, fully automatic metal can filling machines are also versatile and can be customized to meet the specific needs of different sauce products. Whether companies are filling cans with thick or thin sauces, these machines can be adjusted to accommodate various viscosities and textures. This flexibility allows companies to produce a wide range of sauce products without having to invest in multiple filling machines.

Overall, using a fully auto metal can filling machine for sauce production offers numerous advantages, including increased efficiency, precision, and reduced risk of contamination. These machines are designed to streamline the filling process, increase productivity, and ensure the quality and consistency of products. By investing in a fully automatic metal can filling machine, food manufacturers can improve their production processes and meet the demands of the market.