Table of Contents

Benefits of Using an Oil Tin Sealing Machine

An oil tin sealing machine is a valuable piece of equipment that offers numerous benefits to businesses in the oil industry. These machines are designed to efficiently seal tin containers filled with oil, ensuring that the product remains fresh and free from contamination. In this article, we will explore the various benefits of using an oil tin sealing machine in your business operations.

One of the primary benefits of using an oil tin sealing machine is the increased efficiency it provides. These machines are capable of sealing a large number of tin containers in a short amount of time, allowing businesses to meet high production demands without sacrificing quality. This efficiency not only saves time but also reduces labor costs, making it a cost-effective solution for businesses of all sizes.

In addition to efficiency, oil tin sealing machines also offer improved product quality. By sealing tin containers with precision and consistency, these machines help to maintain the freshness and integrity of the oil inside. This is particularly important in the oil industry, where product quality is paramount to customer satisfaction. With an oil tin sealing machine, businesses can ensure that their products reach consumers in the best possible condition.

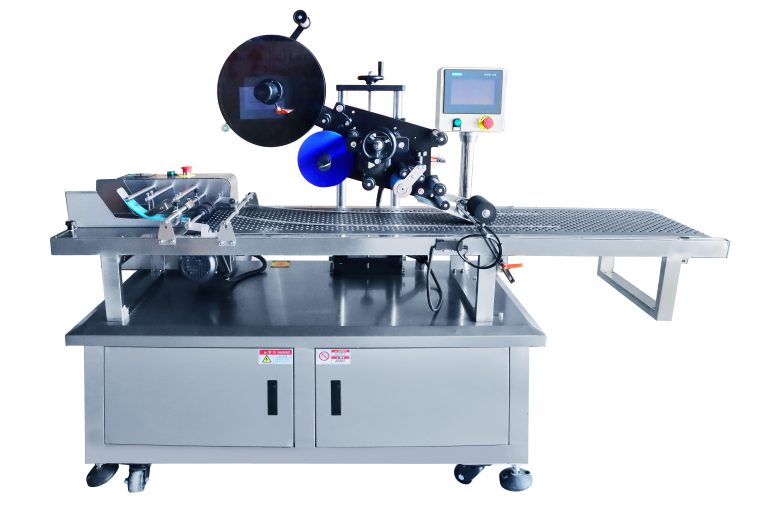

Furthermore, oil tin sealing machines are easy to operate and require minimal training to use effectively. This makes them an ideal solution for businesses looking to streamline their production processes without investing in extensive employee training. With simple controls and user-friendly interfaces, these machines can be operated by workers of all skill levels, making them a versatile and accessible tool for businesses in the oil industry.

Another key benefit of using an oil tin sealing machine is the reduction of waste and product loss. By sealing tin containers with precision, these machines help to minimize the risk of leaks and spills during transportation and storage. This not only saves businesses money on lost product but also helps to protect the environment by reducing the amount of oil that is wasted due to improper sealing.

Additionally, oil tin sealing machines offer businesses greater flexibility in their packaging options. These machines can accommodate a variety of tin container sizes and shapes, allowing businesses to customize their packaging to meet the needs of their customers. Whether sealing small tins for individual sale or larger containers for bulk orders, oil tin sealing machines provide businesses with the flexibility they need to adapt to changing market demands.

In conclusion, the benefits of using an oil tin sealing machine are clear. From increased efficiency and improved product quality to reduced waste and greater flexibility, these machines offer businesses in the oil industry a cost-effective and reliable solution for sealing tin containers. By investing in an oil tin sealing machine, businesses can streamline their production processes, protect their products, and ultimately enhance their bottom line.

How to Choose the Right Oil Tin Sealing Machine for Your Business

Oil tin sealing machines are essential equipment for businesses in the oil industry. These machines are used to seal tin containers securely, ensuring that the oil inside remains fresh and uncontaminated. With so many options available on the market, choosing the right oil tin sealing machine for your business can be a daunting task. In this article, we will discuss some key factors to consider when selecting an oil tin sealing machine to meet your business needs.

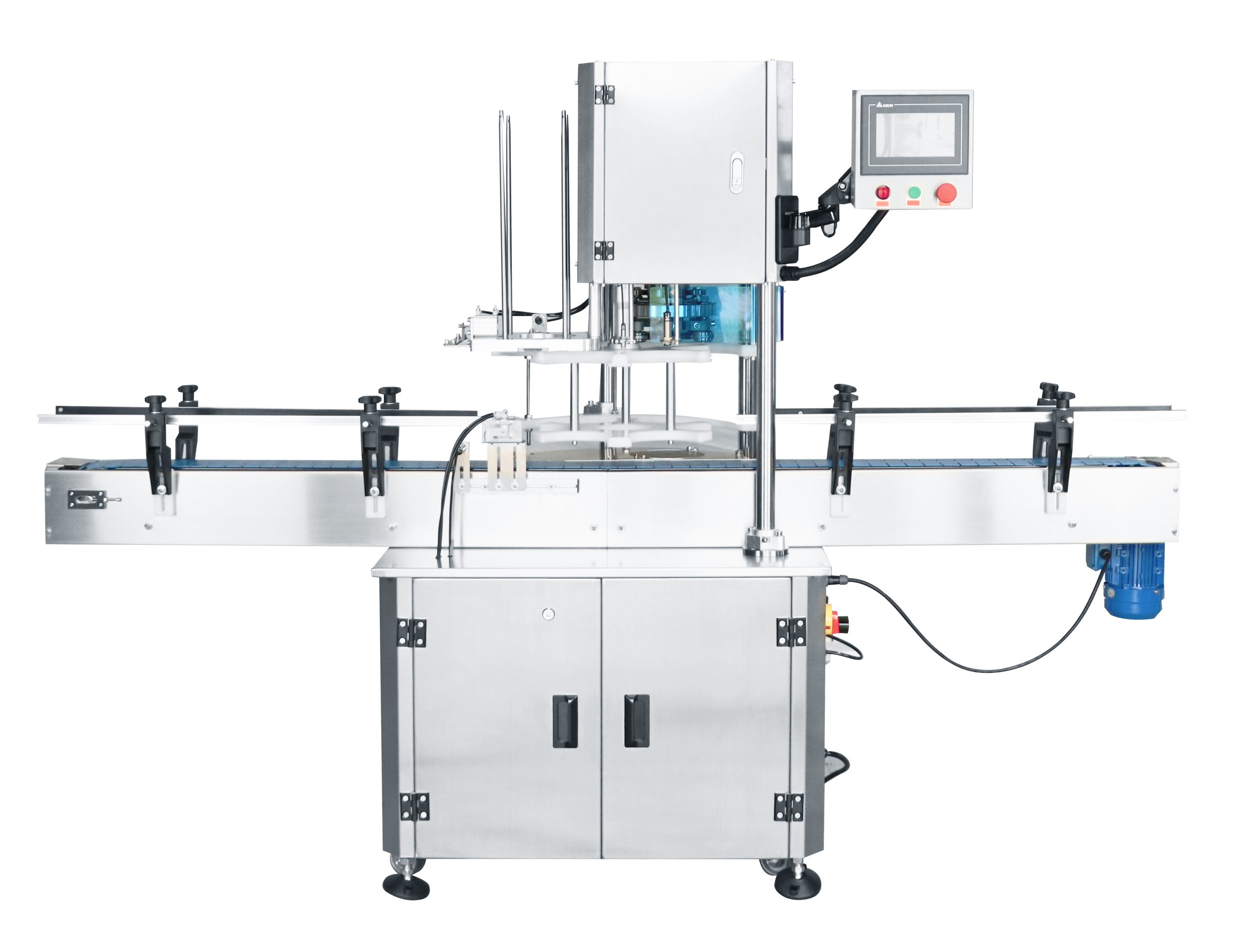

One of the first things to consider when choosing an oil tin sealing machine is the size of your operation. If you have a small business with low production volumes, a manual sealing machine may be sufficient. These machines are typically more affordable and easier to operate, making them a practical choice for small-scale operations. However, if you have a larger business with high production volumes, you may want to invest in a semi-automatic or fully automatic sealing machine. These machines can seal a larger number of tins in a shorter amount of time, increasing efficiency and productivity.

Another important factor to consider when choosing an oil tin sealing machine is the type of tin containers you will be using. Different machines are designed to seal different types and sizes of tins, so it is essential to choose a machine that is compatible with the containers you will be using. Some machines are designed specifically for sealing round tins, while others can seal square or rectangular tins. Additionally, some machines are adjustable and can accommodate a variety of tin sizes, providing flexibility for businesses that use different types of containers.

The sealing method used by the machine is another crucial factor to consider. There are two main types of sealing methods used in oil tin sealing machines: induction sealing and hot air sealing. Induction sealing uses electromagnetic induction to create a hermetic seal on the tin container, while hot air sealing uses heat to melt the sealant and create a secure seal. Each method has its advantages and disadvantages, so it is essential to choose a machine that uses the sealing method that best suits your business needs.

When selecting an oil tin sealing machine, it is also important to consider the speed and efficiency of the machine. The speed at which the machine can seal tins will directly impact your production output, so it is crucial to choose a machine that can seal tins quickly and efficiently. Additionally, some machines come equipped with features such as automatic lid feeding and sealing, which can further increase productivity and streamline the sealing process.

Finally, it is essential to consider the quality and reliability of the oil tin sealing machine. Investing in a high-quality machine from a reputable manufacturer will ensure that your machine operates smoothly and efficiently, reducing the risk of downtime and costly repairs. Additionally, choosing a machine with a warranty and reliable customer support can provide peace of mind and assurance that your investment is protected.

In conclusion, choosing the right oil tin sealing machine for your business is a crucial decision that can impact your production efficiency and product quality. By considering factors such as the size of your operation, the type of tin containers you will be using, the sealing method, speed and efficiency, and the quality of the machine, you can select a machine that meets your business needs and helps you achieve success in the oil industry.

Maintenance Tips for Oil Tin Sealing Machines

Oil tin sealing machines are essential equipment in the packaging industry, used to seal tin cans containing various types of oils. These machines play a crucial role in ensuring the quality and safety of the products being packaged. To maintain the efficiency and longevity of oil tin sealing machines, it is important to follow proper maintenance practices. In this article, we will discuss some key maintenance tips for oil tin sealing machines.

Regular cleaning of the machine is essential to prevent the build-up of oil residue and debris, which can affect the sealing process. It is recommended to clean the machine after each use, using a mild detergent and water. Pay special attention to the sealing components, such as the sealing head and rollers, as any residue on these parts can lead to improper sealing. Additionally, make sure to dry the machine thoroughly after cleaning to prevent rusting.

Inspecting the machine for any signs of wear and tear is another important maintenance practice. Check the sealing components regularly for any damage or deformation, as this can affect the quality of the seals. Replace any worn or damaged parts immediately to prevent further damage to the machine and ensure consistent sealing performance. It is also advisable to lubricate the moving parts of the machine regularly to reduce friction and prolong the lifespan of the components.

Calibrating the machine periodically is crucial to ensure accurate sealing. Over time, the settings of the machine may drift, leading to improper sealing. It is recommended to calibrate the machine at least once a month, or more frequently if the machine is used extensively. Follow the manufacturer’s guidelines for calibration, and make any necessary adjustments to ensure the machine is operating at optimal performance.

In addition to regular maintenance practices, it is important to handle the machine with care to prevent damage. Avoid overloading the machine with cans beyond its capacity, as this can strain the components and lead to premature wear. Handle the cans gently when loading them into the machine to prevent dents or damage to the seals. It is also important to follow proper operating procedures to prevent accidents and ensure the safety of the operators.

Proper storage of the machine when not in use is also essential to maintain its condition. Store the machine in a clean, dry environment away from moisture and dust. Cover the machine with a protective cover to prevent dust and debris from accumulating on the components. It is also advisable to disconnect the machine from power sources when not in use to prevent electrical issues.

By following these maintenance tips, you can ensure the efficiency and longevity of your oil tin sealing machine. Regular cleaning, inspection, calibration, and proper handling are key practices to keep the machine in optimal condition. Remember to follow the manufacturer’s guidelines for maintenance and seek professional help if you encounter any issues with the machine. With proper care and maintenance, your oil tin sealing machine will continue to provide reliable sealing performance for years to come.