Automatic Can Seaming Machine With Nitrogen Gas Flushing

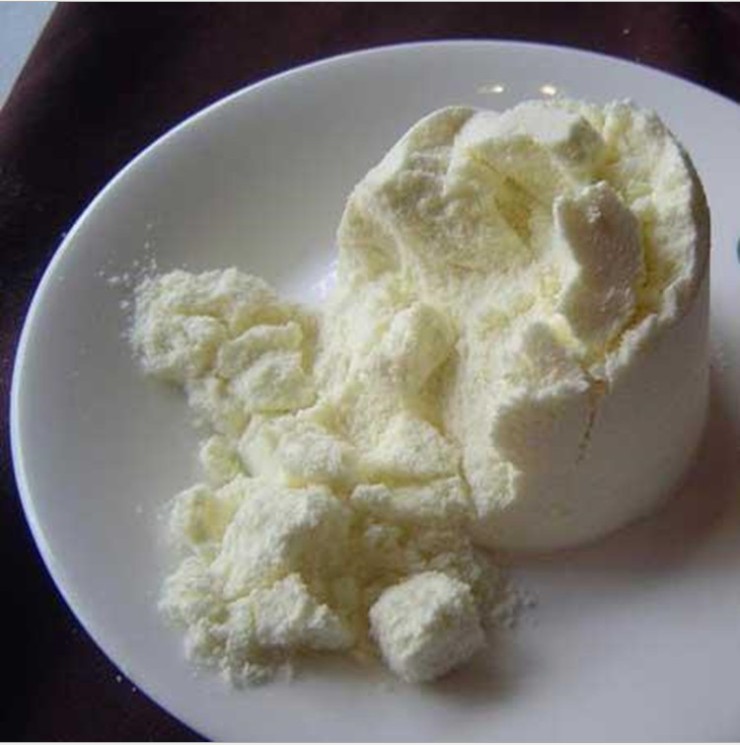

Automatic Can Sealing Machine with Nitrogen Gas Flushing is suitable for sealing of all kinds of round specification ring-pull can of tinplate can, plastic bottle, aluminum alloy can and paper cans.The machine has advanced design, reasonable structure and easy operation, which is the necessary and ideal packaging equipment for food, medicine, milk powders and chemical industries.

Main Features:

1.This equipment is suitable for all kinds of round opening tinplate cans, aluminum cans, plastic cans, paper cans packaged products, first vacuum then nitrogen, and finally sealed. Effectively extend the product shelf life, ideal for food, beverage, pharmaceutical and other industries.

2. Automated control and operation to improve production efficiency and save labor costs

3. The can lid joint control device, when the can body enters, the corresponding cover is provided, if there is no can, there is no cover.

4.Can body does not rotate during the sealing process, which is safe and stable, especially suitable for fragile and liquid products.

5. The seaming rollers and chuck are processed by Cr12 die steel, which is durable and high tightness.

6. The residual oxygen content is less than 3%, effectively extending the shelf life of the product and improving product quality.

Main parameters:

1. Production capacity: 6-7 cans/min;

2. Adaptation range: can diameter φ70-φ127mm, can height 80-190mm

3. Voltage: three-phase 380V 50/60Hz;

4. Machine power: 4KW

5. Weight: 500kg

6. Dimensions: L2000 * W800 *H1850 mm

7. Working pressure (compressed air) ≥0.6MPa

8. Air consumption (compressed air): about 80L/min

9. Nitrogen source pressure ≥0.4MPa

10. Nitrogen consumption: about 50L/min

11. Residual oxygen ≤3%