Table of Contents

Benefits of Using a Washable Can Closing Machine

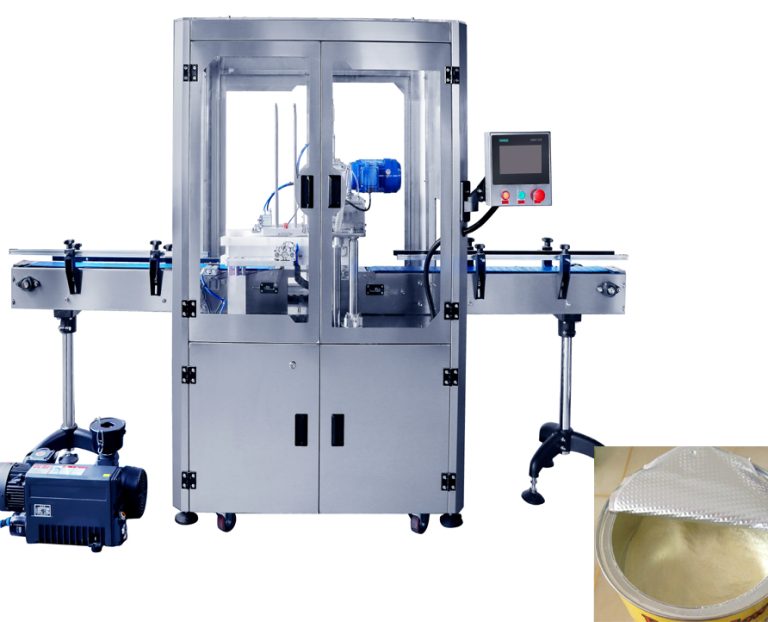

In the beverage industry, efficiency and cleanliness are key factors in ensuring the quality of the final product. One important piece of equipment that plays a crucial role in this process is the can closing machine. These machines are used to seal cans of beverages, such as soda, beer, and energy drinks, to ensure that they are properly sealed and protected from contamination.

One of the main benefits of using a washable can closing machine is that it helps to maintain a high level of cleanliness in the production process. These machines are designed to be easily cleaned and sanitized, which is essential for preventing the growth of bacteria and other contaminants that can spoil the product. By using a washable can closing machine, manufacturers can ensure that their products meet the highest standards of hygiene and safety.

Another benefit of using a washable can closing machine is that it helps to improve efficiency in the production process. These machines are designed to be fast and reliable, allowing manufacturers to seal cans quickly and accurately. This can help to increase productivity and reduce the risk of errors or defects in the final product. By using a washable can closing machine, manufacturers can streamline their production process and ensure that their products are sealed correctly every time.

In addition to improving cleanliness and efficiency, washable can closing machines also offer a number of other benefits. For example, these machines are often designed to be easy to use, with intuitive controls and simple maintenance procedures. This can help to reduce the need for specialized training and make it easier for operators to operate the machine effectively.

Furthermore, washable can closing machines are often designed to be versatile, allowing manufacturers to seal cans of different sizes and shapes. This can be particularly useful for companies that produce a variety of beverage products, as it allows them to use the same machine for different types of cans. By using a washable can closing machine, manufacturers can save time and money by avoiding the need to purchase multiple machines for different products.

Overall, washable can closing machines offer a number of benefits for manufacturers in the beverage industry. From improving cleanliness and efficiency to offering versatility and ease of use, these machines can help to streamline the production process and ensure that products are sealed correctly every time. By investing in a washable can closing machine, manufacturers can improve the quality of their products and maintain a high level of hygiene and safety in their production process.

How to Choose the Right Washable Can Closing Machine for Your Beverage Can

When it comes to packaging beverages in cans, having a reliable can closing machine is essential. These machines are designed to seal cans securely, ensuring that the contents remain fresh and free from contamination. With the increasing demand for sustainable and eco-friendly packaging solutions, washable can closing machines have become a popular choice for many beverage manufacturers. These machines are designed to be easily cleaned and sanitized, making them ideal for use in food and beverage production facilities.

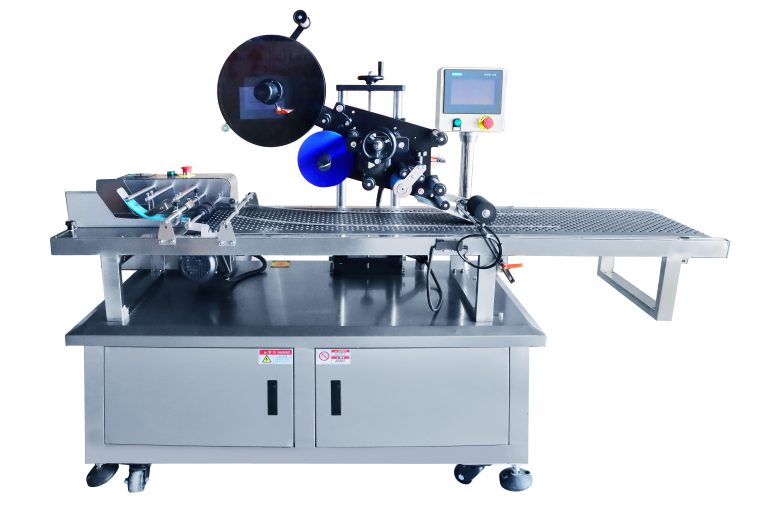

When choosing a washable can closing machine for your beverage can, there are several factors to consider. One of the most important considerations is the size and speed of the machine. You will need to choose a machine that can accommodate the size of your cans and operate at the speed required for your production line. Additionally, you will need to consider the type of closure system that the machine uses. Some machines use traditional seaming technology, while others use more advanced sealing methods such as ultrasonic welding or induction sealing.

Another important factor to consider when choosing a washable can closing machine is the level of automation that the machine offers. Fully automated machines can significantly increase production efficiency and reduce the risk of human error. However, these machines tend to be more expensive than semi-automated or manual machines. It is important to weigh the cost of automation against the potential benefits in terms of increased productivity and reduced labor costs.

In addition to size, speed, closure system, and automation level, you will also need to consider the overall build quality and durability of the machine. A washable can closing machine is a significant investment, so it is important to choose a machine that is built to last. Look for machines that are made from high-quality materials and have a reputation for reliability. It is also a good idea to choose a machine from a reputable manufacturer with a track record of producing high-quality equipment.

When researching washable can closing machines, be sure to read reviews and testimonials from other beverage manufacturers who have used the machines. This can give you valuable insights into the performance and reliability of the machines in real-world production environments. Additionally, consider reaching out to the manufacturer directly to ask any questions you may have about the machine’s capabilities and specifications.

Ultimately, choosing the right washable can closing machine for your beverage can is a decision that should not be taken lightly. Take the time to carefully evaluate your production needs and budget constraints before making a decision. By considering factors such as size, speed, closure system, automation level, build quality, and customer reviews, you can ensure that you choose a machine that meets your requirements and helps you achieve your production goals. With the right washable can closing machine, you can streamline your production process, improve product quality, and meet the demands of your customers.

Maintenance Tips for Ensuring Longevity of Your Washable Can Closing Machine

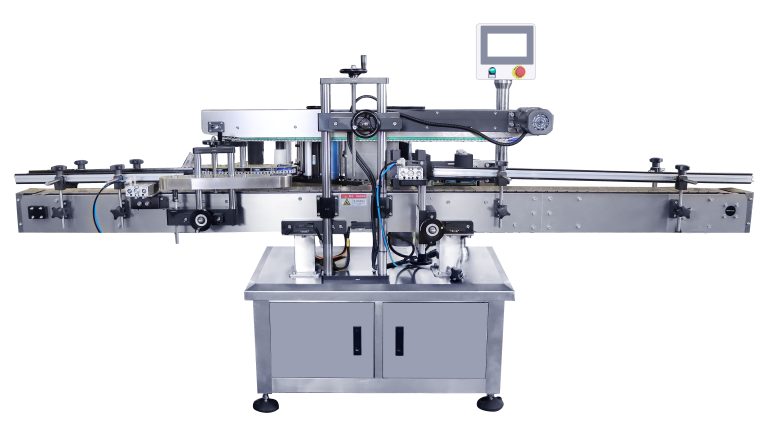

Maintaining your washable can closing machine is essential to ensure its longevity and efficiency. Regular maintenance not only extends the lifespan of the machine but also helps prevent breakdowns and costly repairs. In this article, we will discuss some maintenance tips to help you keep your washable can closing machine in top condition.

First and foremost, it is important to clean your washable can closing machine regularly. Over time, dirt, dust, and debris can accumulate on the machine, affecting its performance. Use a soft cloth and mild detergent to clean the exterior of the machine. Be sure to also clean the interior components, such as the closing head and conveyor belt, to remove any build-up that may impede the machine’s operation.

In addition to regular cleaning, it is important to lubricate the moving parts of the machine. Lubrication helps reduce friction and wear on the components, ensuring smooth operation. Use a high-quality lubricant recommended by the manufacturer and apply it to the designated areas according to the machine’s maintenance manual. Be sure to follow the recommended schedule for lubrication to keep your machine running smoothly.

Another important maintenance tip is to inspect the machine for any signs of wear or damage. Check the closing head, conveyor belt, and other components for any cracks, dents, or other issues that may affect the machine’s performance. Replace any worn or damaged parts immediately to prevent further damage to the machine.

Regularly calibrating your washable can closing machine is also crucial for maintaining its efficiency. Calibration ensures that the machine is closing cans accurately and consistently. Follow the manufacturer’s instructions for calibrating the machine and perform this task regularly to ensure optimal performance.

It is also important to check the machine’s electrical components regularly. Inspect the wiring, switches, and other electrical parts for any signs of damage or wear. Replace any faulty components immediately to prevent electrical issues that may affect the machine’s operation.

Lastly, it is important to train your staff on proper machine operation and maintenance. Ensure that your employees are familiar with the machine’s functions and know how to perform basic maintenance tasks. Provide training on cleaning, lubrication, inspection, and calibration procedures to help prevent issues and ensure the longevity of the machine.

In conclusion, regular maintenance is key to ensuring the longevity and efficiency of your washable can closing machine. By following these maintenance tips, you can keep your machine in top condition and prevent costly repairs. Remember to clean the machine regularly, lubricate moving parts, inspect for wear or damage, calibrate the machine, check electrical components, and train your staff on proper maintenance procedures. By taking care of your washable can closing machine, you can enjoy years of reliable performance and efficiency.