Factors Affecting the Cost of a Canning Line

When it comes to investing in a canning line for your business, there are several factors that can influence the cost. Understanding these factors can help you make an informed decision and ensure that you are getting the best value for your money.

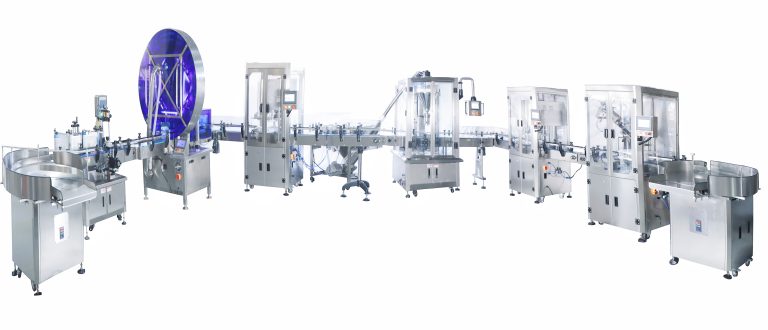

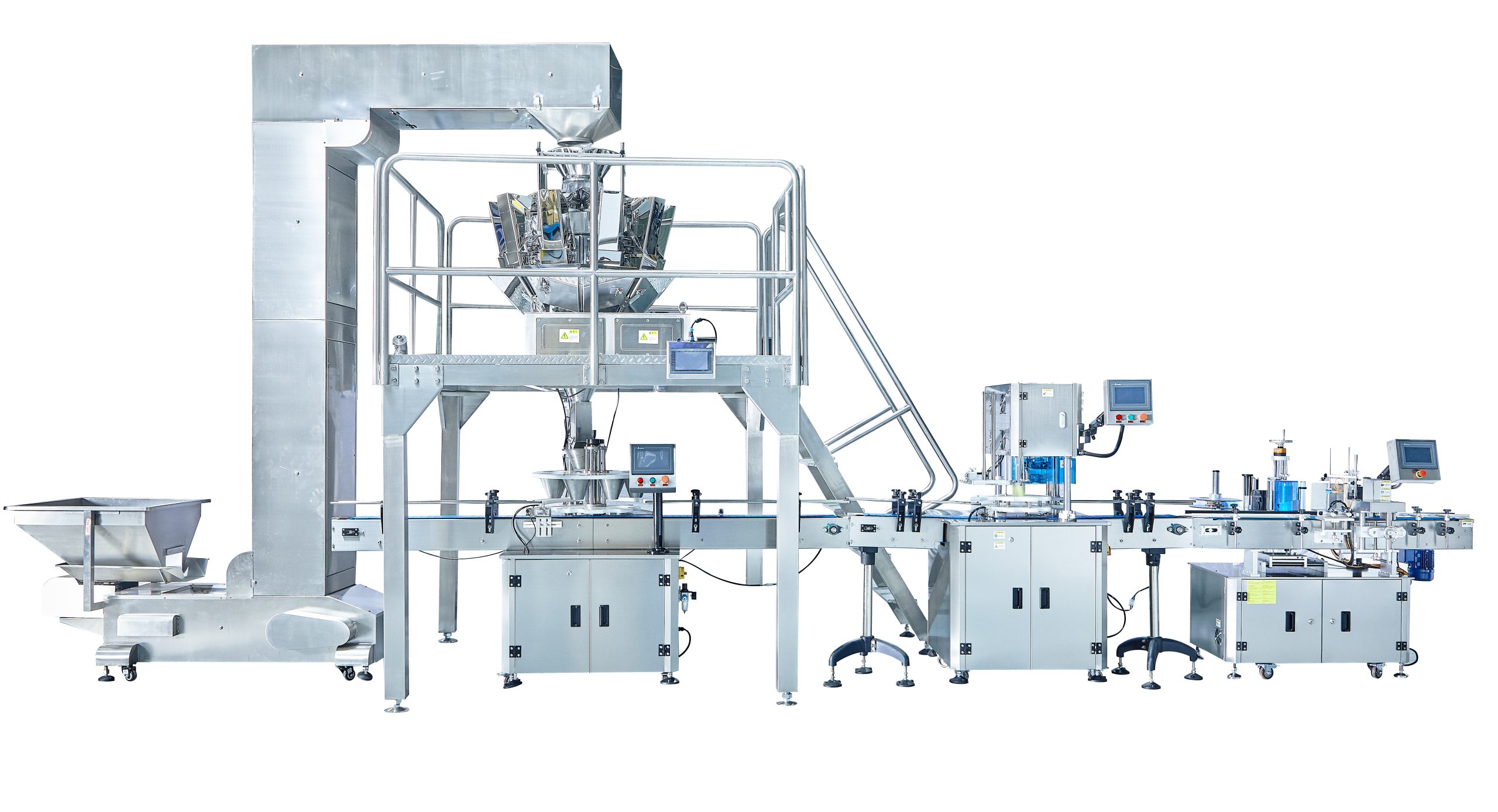

One of the most significant factors that can affect the cost of a canning line is the size and capacity of the machine. Canning lines come in a variety of sizes, ranging from small, manual machines to large, fully automated systems. The size and capacity of the machine will depend on the volume of cans you need to fill and the speed at which you need to fill them. Larger machines with higher capacities will generally cost more than smaller machines.

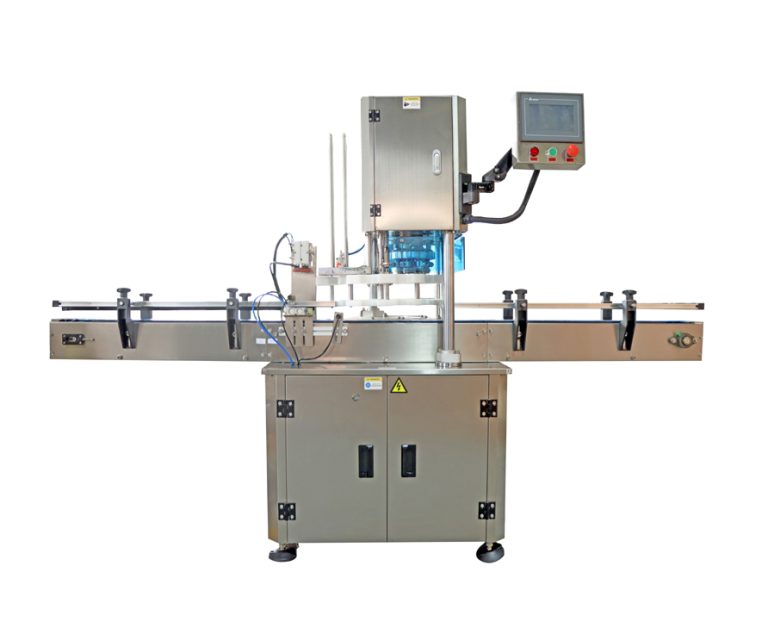

Another factor that can influence the cost of a canning line is the level of automation. Fully automated canning lines are more expensive than semi-automated or manual machines, but they can also increase efficiency and productivity. Automated machines can handle a higher volume of cans and require less manual labor, which can result in cost savings over time. However, if you have a smaller operation or do not need to fill a high volume of cans, a semi-automated or manual machine may be more cost-effective.

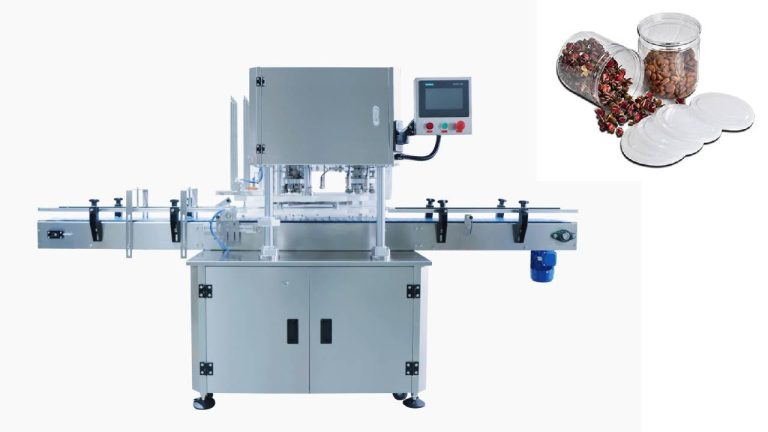

The complexity of the canning line can also impact the cost. Some canning lines are designed to fill only one type of can or product, while others are more versatile and can handle multiple can sizes and products. Machines with more features and capabilities will generally cost more than simpler machines. If you have a diverse product line or anticipate changing can sizes in the future, investing in a more versatile canning line may be worth the additional cost.

The brand and reputation of the manufacturer can also influence the cost of a canning line. Well-known manufacturers with a reputation for quality and reliability may charge more for their machines than lesser-known brands. While it may be tempting to opt for a cheaper machine from a lesser-known manufacturer, it is important to consider the long-term costs of maintenance and repairs. Investing in a high-quality machine from a reputable manufacturer can save you money in the long run by reducing downtime and increasing productivity.

In addition to the initial cost of the canning line, it is important to consider ongoing costs such as maintenance, repairs, and spare parts. Some manufacturers offer warranties and service contracts that can help offset these costs, while others may require you to pay for maintenance and repairs out of pocket. It is important to factor these ongoing costs into your budget when considering the overall cost of a canning line.

In conclusion, there are several factors that can influence the cost of a canning line, including size, capacity, level of automation, complexity, brand, and ongoing costs. By carefully considering these factors and weighing the costs and benefits of different options, you can make an informed decision and choose a canning line that meets your needs and budget.