Table of Contents

Cost-effective Options for Candy Can Packaging Lines

When it comes to packaging candy in cans, choosing the right packaging line is crucial to ensure efficiency and cost-effectiveness. With so many options available in the market, it can be overwhelming to decide which one is the best fit for your specific needs. In this article, we will discuss some key factors to consider when selecting a can packaging line for your candy products.

One of the first things to consider when choosing a can packaging line is the speed and capacity of the machine. Depending on the volume of candy you need to package, you will want to select a packaging line that can keep up with your production demands. Look for a machine that offers high-speed capabilities and can handle a large number of cans per minute to maximize efficiency and productivity.

Another important factor to consider is the flexibility of the packaging line. You may want to package different types of candy in various sizes and shapes of cans, so it is essential to choose a machine that can easily accommodate these variations. Look for a packaging line that offers quick changeover capabilities and can be easily adjusted to accommodate different can sizes and shapes without requiring extensive downtime.

In addition to speed and flexibility, it is also important to consider the overall reliability and durability of the packaging line. You want a machine that can consistently deliver high-quality packaging without frequent breakdowns or malfunctions. Look for a packaging line from a reputable manufacturer with a track record of producing reliable and durable machines that can withstand the rigors of continuous use in a production environment.

Cost is another crucial factor to consider when choosing a can packaging line for your candy products. While it is important to invest in a high-quality machine that can meet your production needs, you also want to ensure that it is cost-effective and offers a good return on investment. Compare the upfront costs of different packaging lines, as well as ongoing maintenance and operating costs, to determine which option offers the best value for your budget.

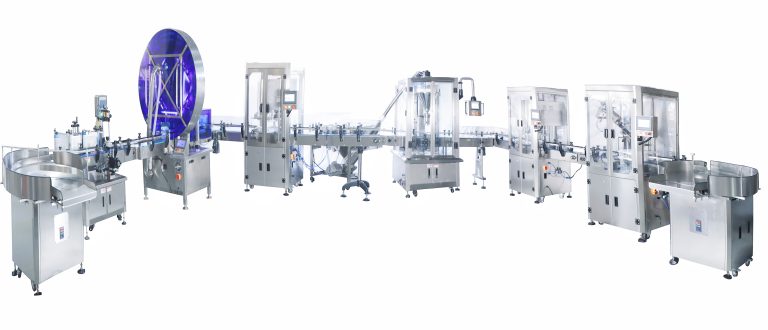

When evaluating different packaging lines, be sure to consider the level of automation and technology offered by each machine. Automated packaging lines can help streamline production processes, reduce labor costs, and improve overall efficiency. Look for a packaging line that offers advanced features such as automatic can feeding, filling, sealing, and labeling to maximize productivity and minimize manual intervention.

Finally, consider the level of customer support and service provided by the manufacturer of the packaging line. You want to work with a company that offers responsive customer support, training, and maintenance services to ensure that your packaging line operates smoothly and efficiently. Look for a manufacturer with a reputation for excellent customer service and a commitment to helping their customers succeed.

In conclusion, choosing the best can packaging line for your candy products requires careful consideration of factors such as speed, flexibility, reliability, cost, automation, and customer support. By evaluating these key factors and selecting a packaging line that meets your specific needs and budget, you can ensure that your candy products are packaged efficiently and cost-effectively to meet the demands of your customers.

Factors to Consider When Selecting a Candy Can Packaging Line

When it comes to packaging candy in cans, choosing the right packaging line is crucial to ensure efficiency and quality. There are several factors to consider when selecting a candy can packaging line that will meet your specific needs and requirements. In this article, we will discuss some key factors to keep in mind when making this important decision.

One of the first things to consider when choosing a candy can packaging line is the speed and capacity of the line. You will need to determine how many cans you need to package per minute or hour, as well as the overall production capacity of the line. It is important to choose a packaging line that can keep up with your production demands without causing bottlenecks or delays.

Another important factor to consider is the size and shape of the cans that you will be using to package your candy. Make sure that the packaging line you choose is compatible with the specific size and shape of cans that you will be using. This will ensure that the cans are properly filled, sealed, and labeled without any issues.

In addition to speed, capacity, and compatibility, it is also important to consider the level of automation that you require in a candy can packaging line. Some packaging lines are fully automated, while others may require more manual labor. Consider your budget and the level of automation that will best suit your production needs.

Furthermore, consider the flexibility of the packaging line. Can it handle different types of candy, sizes of cans, and packaging materials? A flexible packaging line will allow you to easily switch between different products and packaging options without the need for extensive reconfiguration.

It is also important to consider the overall reliability and durability of the packaging line. You want a packaging line that will consistently perform well and require minimal maintenance and repairs. Look for a reputable manufacturer with a track record of producing high-quality, reliable packaging equipment.

Cost is another important factor to consider when choosing a candy can packaging line. While it is important to stay within your budget, it is also important to consider the long-term costs associated with the packaging line. Consider factors such as energy efficiency, maintenance costs, and the overall lifespan of the equipment.

Finally, consider the level of support and service that the manufacturer provides. Choose a manufacturer that offers comprehensive training, technical support, and maintenance services to ensure that your packaging line continues to operate smoothly and efficiently.

In conclusion, choosing the best candy can packaging line for your specific needs requires careful consideration of factors such as speed, capacity, compatibility, automation, flexibility, reliability, cost, and support. By taking the time to thoroughly evaluate these factors, you can select a packaging line that will help you package your candy efficiently and effectively.