Table of Contents

Manfaat Menggunakan Mesin Penyegel Kaleng Otomatis

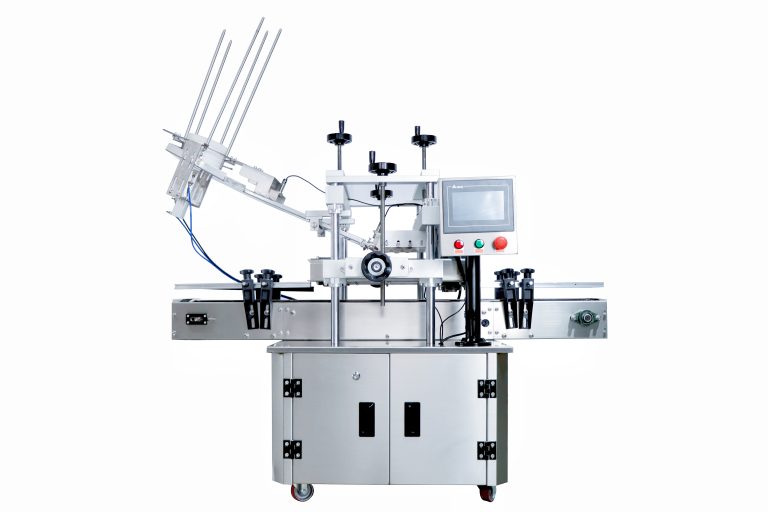

Dalam dunia pengemasan makanan, efisiensi dan kualitas adalah faktor kunci yang dapat menentukan keberhasilan atau kehancuran suatu bisnis. Salah satu peralatan penting yang dapat meningkatkan proses pengemasan secara signifikan adalah mesin penyegel kaleng otomatis. Mesin ini dirancang untuk menyegel kaleng dengan cepat dan efisien, memastikan isi di dalamnya terlindungi dan awet untuk jangka waktu yang lebih lama. Ada banyak keuntungan menggunakan mesin penyegel kaleng otomatis, menjadikannya investasi berharga untuk setiap pengoperasian pengemasan makanan.

Salah satu manfaat utama menggunakan mesin penyegel kaleng otomatis adalah kecepatan penyegelan kaleng. Mesin-mesin ini mampu menyegel ratusan kaleng per jam, sehingga secara signifikan meningkatkan produktivitas lini pengemasan. Hal ini dapat membantu bisnis memenuhi tenggat waktu yang ketat dan memenuhi permintaan yang tinggi, yang pada akhirnya meningkatkan keuntungan dan kepuasan pelanggan.

Selain kecepatan, mesin penyegel kaleng otomatis juga menawarkan tingkat presisi dan konsistensi yang tinggi. Metode penyegelan manual rentan terhadap kesalahan manusia, sehingga mengakibatkan kaleng tidak tersegel dengan benar sehingga dapat membahayakan kualitas dan keamanan produk di dalamnya. Sebaliknya, mesin otomatis diprogram untuk menyegel kaleng dengan presisi setiap saat, memastikan segel yang rapat dan aman sehingga isinya tetap segar dan bebas kontaminasi.

Manfaat lain menggunakan mesin penyegel kaleng otomatis adalah pengurangan biaya tenaga kerja. Metode penyegelan manual memerlukan banyak tenaga kerja, karena pekerja harus menutup setiap kaleng dengan hati-hati. Hal ini dapat memakan waktu dan padat karya, sehingga menyebabkan biaya tenaga kerja yang lebih tinggi bagi bisnis. Sebaliknya, mesin otomatis hanya membutuhkan sedikit campur tangan manusia, sehingga bisnis dapat mengalokasikan sumber daya mereka secara lebih efisien dan mengurangi biaya tenaga kerja dalam jangka panjang.

Selain itu, mesin penyegel kaleng otomatis dirancang agar ramah pengguna dan mudah dioperasikan . Banyak mesin dilengkapi dengan kontrol dan pengaturan intuitif yang dapat dengan mudah disesuaikan untuk mengakomodasi berbagai ukuran kaleng dan persyaratan penyegelan. Hal ini memudahkan operator untuk menyiapkan dan menjalankan mesin, mengurangi kebutuhan akan pelatihan ekstensif, dan memastikan proses pengemasan yang lancar dan efisien.

Selain manfaat praktis ini, mesin penyegel kaleng otomatis juga menawarkan serangkaian fitur keselamatan yang membantu melindungi pekerja dan mencegah kecelakaan. Banyak alat berat dilengkapi dengan sensor dan alarm yang mengingatkan operator akan masalah atau malfungsi apa pun, sehingga memungkinkan mereka mengatasi masalah dengan cepat dan mencegah potensi cedera. Fokus pada keselamatan ini tidak hanya melindungi pekerja tetapi juga membantu bisnis menjaga lingkungan kerja yang aman dan patuh.

Secara keseluruhan, manfaat menggunakan mesin penyegel kaleng otomatis sudah jelas. Mulai dari peningkatan produktivitas dan efisiensi hingga peningkatan kualitas dan keamanan, mesin-mesin ini menawarkan serangkaian keunggulan yang dapat membantu bisnis menyederhanakan proses pengemasan dan mencapai kesuksesan yang lebih besar. Baik Anda produsen skala kecil atau produsen skala besar, berinvestasi pada mesin penyegel kaleng otomatis adalah keputusan cerdas yang dapat berdampak positif pada keuntungan Anda.

Cara Memilih Mesin Penyegel Kaleng Otomatis Terbaik untuk Pabrik Anda

Saat memilih mesin penyegel kaleng otomatis terbaik untuk pabrik Anda, ada beberapa faktor yang perlu dipertimbangkan. Mulai dari ukuran dan kecepatan mesin hingga kualitas segel yang dihasilkannya, menemukan mesin yang tepat dapat memberikan dampak yang signifikan pada proses produksi Anda. Pada artikel ini, kita akan membahas beberapa pertimbangan utama yang perlu diperhatikan saat memilih mesin penyegel kaleng otomatis untuk pabrik Anda.

Salah satu hal pertama yang perlu diperhatikan saat memilih mesin penyegel kaleng otomatis adalah ukuran mesinnya. Ukuran mesin akan bergantung pada volume kaleng yang perlu Anda segel setiap hari. Jika Anda memiliki kaleng dalam jumlah besar untuk disegel, Anda memerlukan mesin yang lebih besar yang dapat menangani beban kerja secara efisien. Sebaliknya, jika Anda memiliki lini produksi yang lebih kecil, mesin yang lebih kecil mungkin lebih sesuai dengan kebutuhan Anda.

Selain ukuran, kecepatan mesin merupakan faktor penting lainnya yang perlu dipertimbangkan. Kecepatan mesin akan menentukan seberapa cepat Anda dapat menyegel kaleng, yang dapat berdampak langsung pada efisiensi produksi Anda secara keseluruhan. Penting untuk memilih mesin yang dapat menyegel kaleng dengan kecepatan yang sesuai dengan kecepatan lini produksi Anda.

Pertimbangan penting lainnya saat memilih mesin penyegel kaleng otomatis adalah kualitas segel yang dihasilkannya. Kualitas segel sangat penting untuk memastikan produk Anda tersegel dengan benar dan terlindung dari kontaminasi. Carilah mesin yang menghasilkan segel yang konsisten dan berkualitas tinggi untuk menghindari masalah pembusukan atau kebocoran produk.

Saat memilih mesin penyegel kaleng otomatis, penting juga untuk mempertimbangkan kemudahan penggunaan dan perawatan mesin. Mesin yang mudah dioperasikan dan dirawat akan membantu memperlancar proses produksi Anda dan meminimalkan downtime. Carilah mesin yang dilengkapi dengan petunjuk jelas serta mudah dibersihkan dan dirawat.

Selain itu, penting untuk mempertimbangkan reputasi produsen saat memilih mesin penyegel kaleng otomatis. Carilah produsen dengan rekam jejak yang terbukti memproduksi mesin berkualitas tinggi yang andal dan tahan lama. Membaca ulasan dan testimoni dari pelanggan lain dapat membantu Anda mengukur kualitas mesin dan tingkat dukungan pelanggan yang diberikan oleh produsen.

Kesimpulannya, memilih mesin penyegel kaleng otomatis terbaik untuk pabrik Anda memerlukan pertimbangan yang cermat terhadap beberapa faktor utama . Mulai dari ukuran dan kecepatan mesin hingga kualitas segel yang dihasilkan, menemukan mesin yang tepat dapat berdampak signifikan pada proses produksi Anda. Dengan meluangkan waktu untuk meneliti dan mengevaluasi pilihan Anda, Anda dapat menemukan mesin yang memenuhi kebutuhan spesifik Anda dan membantu meningkatkan efisiensi lini produksi Anda.

Studi Kasus: Keberhasilan Penerapan Mesin Penyegel Kaleng Otomatis di Pabrik

Dalam dunia manufaktur, efisiensi dan presisi adalah faktor kunci dalam memastikan keberhasilan sebuah pabrik. Salah satu aspek penting dalam proses produksi adalah penyegelan kaleng, yang merupakan tugas yang memerlukan ketelitian dan konsistensi. Penyegelan kaleng secara manual memakan waktu dan rentan terhadap kesalahan, itulah sebabnya banyak pabrik beralih ke mesin penyegel kaleng otomatis untuk menyederhanakan operasinya.

Salah satu pabrik yang berhasil menerapkan mesin penyegel kaleng otomatis adalah Pabrik Terbaik . Terletak di jantung kawasan industri, Best Factory dikenal dengan produk berkualitas tinggi dan proses produksi yang efisien. Ketika pabrik memutuskan untuk meningkatkan proses penyegelan kaleng, mereka beralih ke mesin penyegel otomatis untuk meningkatkan efisiensi dan mengurangi risiko kesalahan.

Mesin penyegel kaleng otomatis di Best Factory dilengkapi dengan teknologi canggih yang menjamin kekencangan dan segel aman pada setiap kaleng. Mesin ini mampu menyegel ratusan kaleng per menit, sehingga meningkatkan hasil produksi pabrik secara signifikan. Peningkatan efisiensi ini memungkinkan Best Factory memenuhi permintaan produk mereka yang terus meningkat tanpa mengurangi kualitas.

Salah satu keunggulan utama mesin penyegel kaleng otomatis di Best Factory adalah konsistensinya. Kualitas penyegelan manual dapat bervariasi tergantung pada operatornya, namun mesin otomatis memastikan bahwa setiap kaleng disegel dengan tingkat presisi yang sama setiap saat. Konsistensi ini telah membantu Best Factory mempertahankan reputasinya atas produk-produk berkualitas tinggi dan membuat mereka mendapatkan kepercayaan dari pelanggannya.

Keuntungan lain dari mesin penyegel kaleng otomatis adalah kecepatannya. Dengan kemampuan menyegel ratusan kaleng per menit, mesin ini secara drastis mengurangi waktu yang dibutuhkan untuk menyelesaikan proses penyegelan. Hal ini memungkinkan Best Factory meningkatkan kapasitas produksinya dan memenuhi tenggat waktu yang ketat tanpa mengorbankan kualitas.

Selain efisiensi dan konsistensi, mesin penyegel kaleng otomatis di Best Factory juga meningkatkan keamanan proses penyegelan. Penyegelan manual bisa menjadi tugas yang berbahaya, karena melibatkan penanganan ujung yang tajam dan peralatan penyegelan yang panas. Mesin otomatis menghilangkan kebutuhan akan intervensi manual, sehingga mengurangi risiko kecelakaan dan cedera di pabrik.

Secara keseluruhan, penerapan mesin penyegel kaleng otomatis di Best Factory telah sukses besar. Mesin ini telah meningkatkan efisiensi, konsistensi, dan keamanan dalam proses penyegelan, memungkinkan pabrik meningkatkan hasil produksi dan memenuhi permintaan pelanggan. Best Factory telah menetapkan standar baru untuk penyegelan kaleng di industri, dan pabrik lain kini ingin mengikuti jejak mereka dalam menerapkan mesin penyegel otomatis.

Kesimpulannya, mesin penyegel kaleng otomatis di Best Factory adalah contoh cemerlang dari keberhasilan penerapannya di industri manufaktur. Dengan teknologi canggih, efisiensi, dan konsistensi, alat berat ini telah merevolusi proses penyegelan dan menetapkan standar baru untuk kualitas dan produktivitas. Karena semakin banyak pabrik yang ingin meningkatkan operasinya, mesin penyegel kaleng otomatis pasti akan menjadi kebutuhan pokok di industri ini.