Table of Contents

Food and Beverage Industry

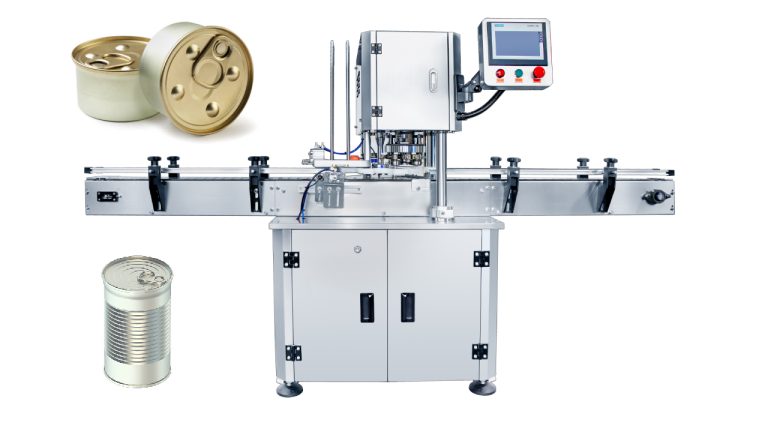

Round can closing machines are versatile pieces of equipment that can be utilized in a variety of industries. One industry where these machines are commonly used is the food and beverage industry. In this sector, round can closing machines play a crucial role in ensuring that products are properly sealed and preserved for consumption.

In the food and beverage industry, round can closing machines are used to seal cans of various sizes and shapes. These machines are designed to provide a tight seal on cans, preventing air and moisture from entering and spoiling the contents. This is essential for preserving the quality and freshness of food and beverage products, ensuring that they remain safe for consumption.

One of the key benefits of using round can closing machines in the food and beverage industry is that they help to extend the shelf life of products. By providing a secure seal on cans, these machines help to prevent contamination and spoilage, allowing products to be stored for longer periods without compromising their quality. This is particularly important for perishable items such as fruits, vegetables, and dairy products, which can spoil quickly if not properly sealed.

Round can closing machines are also used in the food and beverage industry to maintain product integrity. By sealing cans effectively, these machines help to protect the contents from external contaminants, such as dust, dirt, and bacteria. This is essential for ensuring that products meet quality and safety standards, and that they are safe for consumers to consume.

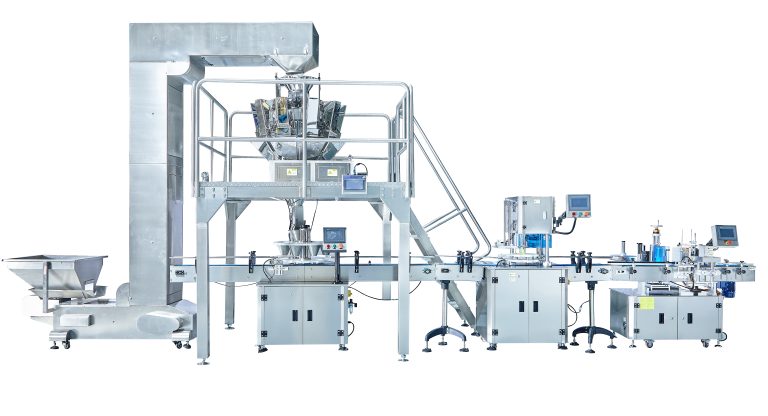

In addition to preserving product quality and integrity, round can closing machines also help to improve efficiency in the food and beverage industry. These machines are designed to seal cans quickly and accurately, reducing the need for manual labor and increasing production output. This can help food and beverage manufacturers to meet demand more effectively, and to streamline their operations for greater efficiency.

Another key advantage of using round can closing machines in the food and beverage industry is that they can be customized to meet specific production requirements. These machines can be adjusted to accommodate different can sizes and shapes, as well as different sealing methods. This flexibility allows manufacturers to seal a wide range of products, from canned fruits and vegetables to beverages and soups, with precision and consistency.

Overall, round can closing machines are an essential piece of equipment in the food and beverage industry. These machines play a crucial role in preserving product quality and integrity, extending shelf life, and improving efficiency in production. By utilizing round can closing machines, food and beverage manufacturers can ensure that their products are properly sealed and preserved for consumption, meeting quality and safety standards, and satisfying consumer demand.

Pharmaceutical Industry

Round can closing machines are versatile pieces of equipment that can be utilized in a variety of industries, including the pharmaceutical industry. These machines are designed to securely seal cans, ensuring that the contents remain fresh and protected from external contaminants. In the pharmaceutical industry, where product safety and quality are of utmost importance, round can closing machines play a crucial role in the packaging process.

One of the key benefits of using round can closing machines in the pharmaceutical industry is their ability to provide a hermetic seal. This seal helps to prevent moisture, air, and other contaminants from entering the can, which can compromise the integrity of the product inside. By ensuring a tight seal, round can closing machines help to extend the shelf life of pharmaceutical products, maintaining their efficacy and safety for longer periods.

In addition to providing a secure seal, round can closing machines also offer a high level of precision and consistency in the sealing process. This is particularly important in the pharmaceutical industry, where even the slightest deviation in the sealing process can have serious consequences. By using a round can closing machine, pharmaceutical companies can ensure that each can is sealed with the same level of accuracy, reducing the risk of product spoilage or contamination.

Furthermore, round can closing machines are designed to handle a wide range of can sizes and materials, making them suitable for use in various packaging applications within the pharmaceutical industry. Whether packaging tablets, capsules, powders, or liquids, pharmaceutical companies can rely on round can closing machines to provide a reliable and efficient sealing solution.

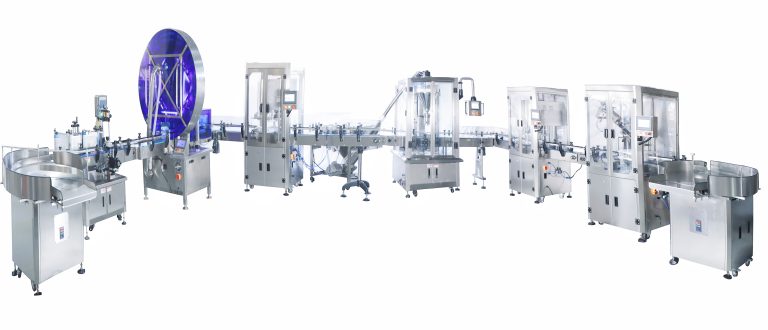

Another advantage of using round can closing machines in the pharmaceutical industry is their ability to increase production efficiency. These machines are capable of sealing cans at a high speed, allowing pharmaceutical companies to meet the demands of a fast-paced production environment. By automating the sealing process, round can closing machines help to streamline operations and reduce the risk of human error, ultimately improving overall productivity.

Moreover, round can closing machines are easy to operate and maintain, requiring minimal training for operators. This makes them a cost-effective solution for pharmaceutical companies looking to enhance their packaging processes without incurring significant additional expenses. With proper maintenance and regular servicing, round can closing machines can provide years of reliable performance, making them a valuable investment for pharmaceutical manufacturers.

In conclusion, round can closing machines are a versatile and efficient solution for sealing cans in the pharmaceutical industry. With their ability to provide a hermetic seal, precision sealing capabilities, versatility in handling different can sizes and materials, and potential to increase production efficiency, these machines offer numerous benefits to pharmaceutical companies. By incorporating round can closing machines into their packaging processes, pharmaceutical manufacturers can ensure the safety, quality, and integrity of their products, ultimately enhancing customer satisfaction and brand reputation.

Chemical Industry

Round can closing machines are versatile pieces of equipment that can be utilized in a variety of industries. One such industry where these machines are commonly used is the chemical industry. In the chemical industry, round can closing machines play a crucial role in the packaging process, ensuring that products are securely sealed and protected from contamination.

Chemical products come in a wide range of shapes and sizes, and round cans are a popular choice for packaging these products. Round can closing machines are specifically designed to seal round cans with precision and efficiency, making them an essential tool for manufacturers in the chemical industry. These machines can handle a variety of can sizes and materials, allowing for flexibility in the packaging process.

One of the key benefits of using round can closing machines in the chemical industry is the ability to maintain product integrity. By securely sealing cans, these machines help prevent leaks and spills, ensuring that chemical products remain safe and uncontaminated during storage and transportation. This is especially important for hazardous chemicals, where even a small leak can have serious consequences.

In addition to ensuring product integrity, round can closing machines also help improve efficiency in the packaging process. These machines are capable of sealing cans quickly and accurately, reducing the time and labor required for manual sealing. This not only increases productivity but also helps reduce the risk of human error, ensuring consistent and reliable sealing for every can.

Furthermore, round can closing machines are designed to meet the strict safety standards required in the chemical industry. These machines are equipped with safety features such as emergency stop buttons and protective guards to prevent accidents and injuries. By investing in a high-quality round can closing machine, manufacturers can ensure a safe working environment for their employees while maintaining compliance with industry regulations.

Another advantage of using round can closing machines in the chemical industry is the ability to customize the sealing process to meet specific requirements. These machines can be programmed to adjust the sealing pressure, speed, and other parameters to accommodate different types of cans and products. This flexibility allows manufacturers to seal a wide range of chemical products with precision and consistency.

In conclusion, round can closing machines are an essential tool for manufacturers in the chemical industry. These machines offer a range of benefits, including maintaining product integrity, improving efficiency, ensuring safety, and providing customization options. By investing in a high-quality round can closing machine, manufacturers can streamline their packaging process, protect their products, and meet the stringent requirements of the chemical industry.