Benefits of Using a Capping Machine

Packaging plays a crucial role in the success of a product. It not only protects the product during transportation and storage but also serves as a marketing tool to attract consumers. One important aspect of packaging is the closure or capping of the container. Choosing the right capping machine can significantly impact the efficiency and quality of your packaging process. In this article, we will discuss the benefits of using a capping machine and provide a guide to help you choose the right one for your packaging needs.

One of the main benefits of using a capping machine is increased efficiency. Manual capping can be time-consuming and labor-intensive, especially for products that require a high volume of containers to be capped. A capping machine automates the process, allowing for faster and more consistent capping of containers. This not only saves time but also reduces the risk of human error, resulting in a more reliable and efficient packaging process.

Another benefit of using a capping machine is improved quality control. Manual capping can lead to inconsistencies in the torque applied to the cap, which can result in leaks or other issues with the product. A capping machine allows for precise control over the torque applied to the cap, ensuring a secure and consistent seal on every container. This helps to maintain the quality and integrity of the product, reducing the risk of spoilage or contamination.

In addition to efficiency and quality control, using a capping machine can also help to reduce costs. While there is an initial investment required to purchase a capping machine, the long-term savings in labor costs and reduced product waste can outweigh this initial expense. By automating the capping process, you can increase the productivity of your packaging line and reduce the need for manual labor, ultimately saving time and money in the long run.

Furthermore, using a capping machine can also improve the overall safety of your packaging process. Manual capping can be physically demanding and repetitive, leading to potential injuries or strain on workers. By automating the capping process, you can reduce the risk of injuries and create a safer working environment for your employees. This not only protects your workers but also helps to ensure a more efficient and productive packaging process.

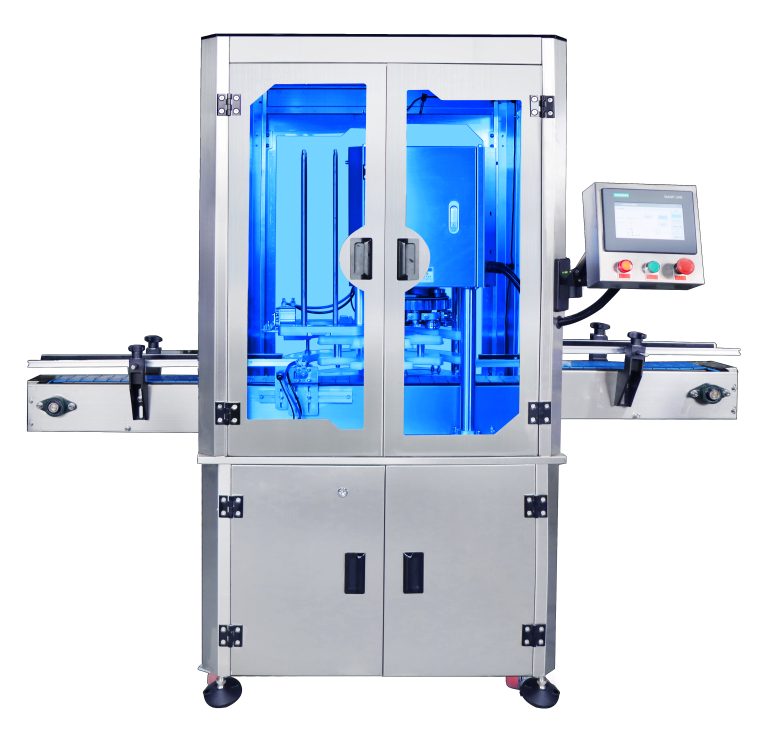

When choosing a capping machine for your packaging line, there are several factors to consider. First, you should assess the size and type of containers you will be capping, as well as the volume of production. Different capping machines are designed for different types of containers and production levels, so it is important to choose one that is suitable for your specific needs.

You should also consider the type of closure you will be using, as different capping machines are designed to work with specific types of caps, such as screw caps, snap caps, or press-on caps. Additionally, you should consider the level of automation you require, as some capping machines offer fully automated systems, while others may require some manual intervention.

In conclusion, using a capping machine can offer numerous benefits for your packaging process, including increased efficiency, improved quality control, cost savings, and enhanced safety. By choosing the right capping machine for your specific needs, you can optimize your packaging process and ensure the success of your product in the market.