Table of Contents

Benefits of Using Automated Tape Around Sealing Machine

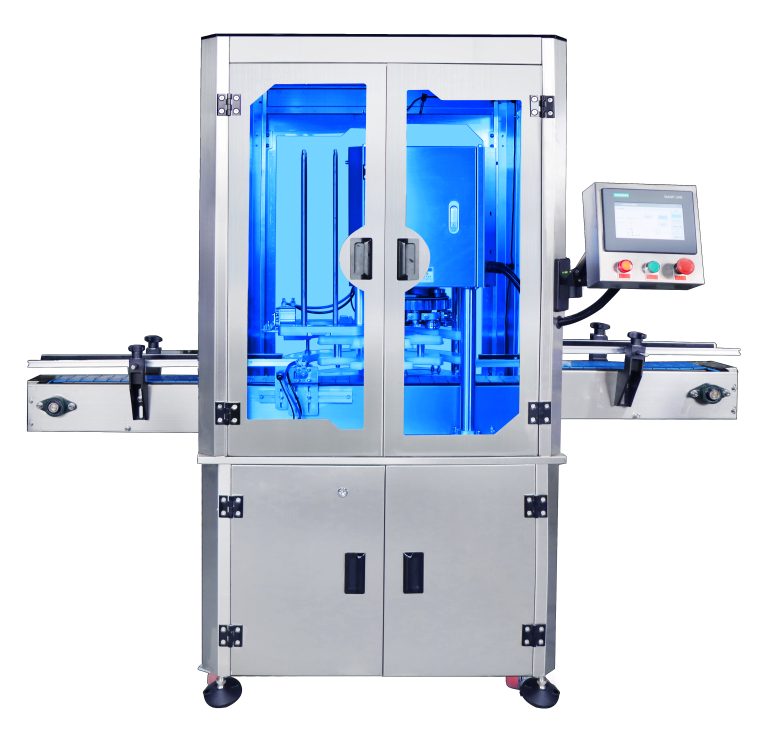

Automated tape around sealing machines have revolutionized the packaging industry by providing a fast, efficient, and cost-effective solution for sealing boxes and cartons. These machines are designed to automatically apply tape around the edges of boxes, ensuring a secure and professional seal every time. In this article, we will explore the benefits of using automated tape around sealing machines and why they are a valuable investment for businesses of all sizes.

One of the primary benefits of using an automated tape around sealing machine is the time and labor savings it provides. Manual sealing of boxes can be a time-consuming and tedious process, requiring employees to spend hours applying tape by hand. With an automated machine, boxes can be sealed in a fraction of the time, allowing employees to focus on more important tasks. This not only increases productivity but also reduces labor costs, making the machine a cost-effective solution for businesses.

In addition to saving time and labor, automated tape around sealing machines also provide a consistent and professional seal on every box. Manual sealing can result in uneven or poorly applied tape, leading to potential damage or tampering during shipping. Automated machines ensure that the tape is applied evenly and securely, reducing the risk of damage and ensuring that boxes arrive at their destination in pristine condition. This not only improves customer satisfaction but also helps to protect the reputation of the business.

Another benefit of using an automated tape around sealing machine is the versatility it provides. These machines are capable of sealing boxes of various sizes and shapes, making them suitable for a wide range of packaging needs. Whether you are sealing small boxes for retail shipments or large cartons for industrial purposes, an automated machine can handle the job with ease. This versatility makes the machine a valuable investment for businesses that have diverse packaging requirements.

Furthermore, automated tape around sealing machines are easy to operate and require minimal maintenance. Once the machine is set up and calibrated, it can run continuously without the need for constant supervision. This allows businesses to streamline their packaging process and reduce the risk of errors or downtime. Additionally, most machines are equipped with safety features to protect operators and prevent accidents, making them a safe and reliable option for businesses.

In conclusion, automated tape around sealing machines offer a wide range of benefits for businesses looking to improve their packaging process. From time and labor savings to consistent and professional seals, these machines provide a cost-effective solution for businesses of all sizes. With their versatility, ease of operation, and minimal maintenance requirements, automated machines are a valuable investment that can help businesses streamline their packaging operations and improve efficiency. If you are looking to enhance your packaging process and increase productivity, consider investing in an automated tape around sealing machine today.

How to Choose the Right Automated Tape Around Sealing Machine for Your Business

Automated tape around sealing machines are a crucial piece of equipment for businesses that require efficient and reliable packaging solutions. These machines are designed to quickly and accurately seal packages with tape, saving time and labor costs. However, with so many options available on the market, choosing the right automated tape around sealing machine for your business can be a daunting task. In this comprehensive guide, we will discuss the key factors to consider when selecting an automated tape around sealing machine to ensure that you make the best choice for your business needs.

One of the first things to consider when choosing an automated tape around sealing machine is the type of packaging materials you will be using. Different machines are designed to work with specific types of tape, so it is important to choose a machine that is compatible with the tape you plan to use. Additionally, consider the size and weight of the packages you will be sealing, as this will impact the size and capacity of the machine you need.

Another important factor to consider is the speed and efficiency of the machine. Look for a machine that can handle the volume of packages you need to seal in a timely manner. Some machines are capable of sealing hundreds of packages per hour, while others may only be able to handle a few dozen. Consider your business’s production needs and choose a machine that can keep up with demand.

In addition to speed and efficiency, it is important to consider the durability and reliability of the machine. Look for a machine that is built to last and can withstand the rigors of daily use. Check for features such as heavy-duty construction, high-quality components, and a solid warranty to ensure that your investment will pay off in the long run.

When choosing an automated tape around sealing machine, it is also important to consider the ease of use and maintenance. Look for a machine that is user-friendly and intuitive, with clear instructions and easy-to-use controls. Additionally, consider the maintenance requirements of the machine, such as cleaning and lubrication, and choose a machine that is easy to maintain to keep it running smoothly.

Finally, consider the cost of the machine and your budget. Automated tape around sealing machines can vary widely in price, so it is important to choose a machine that fits within your budget while still meeting your business needs. Consider the long-term costs of ownership, including maintenance and repair costs, to ensure that you are making a sound investment.

In conclusion, choosing the right automated tape around sealing machine for your business is a crucial decision that can impact your productivity and efficiency. Consider factors such as the type of packaging materials you will be using, the speed and efficiency of the machine, its durability and reliability, ease of use and maintenance, and cost when making your decision. By carefully evaluating these factors and choosing a machine that meets your business needs, you can ensure that you are making the best choice for your business.

Maintenance Tips for Automated Tape Around Sealing Machine

Automated tape around sealing machines are essential tools in the packaging industry, providing a quick and efficient way to seal boxes and packages. To ensure that your machine continues to operate at its best, regular maintenance is key. In this comprehensive guide, we will provide you with some essential maintenance tips to keep your automated tape around sealing machine in top condition.

First and foremost, it is important to regularly clean your machine to prevent any build-up of dust, dirt, or debris. This can cause the machine to operate less efficiently and may even lead to malfunctions. Use a soft cloth and a mild detergent to wipe down the machine, paying special attention to the rollers and cutting blades. Be sure to also clean the tape dispenser and any other moving parts to keep them running smoothly.

In addition to cleaning, it is important to regularly inspect your machine for any signs of wear and tear. Check the belts, gears, and other components for any signs of damage or excessive wear. If you notice any issues, it is important to address them promptly to prevent further damage to the machine. Regular inspections can help you catch potential problems early on and avoid costly repairs down the line.

Another important maintenance tip is to regularly lubricate the moving parts of your machine. This will help reduce friction and wear on the components, extending the life of your machine. Be sure to use a lubricant that is recommended by the manufacturer and follow their guidelines for application. Over-lubricating can cause just as many issues as under-lubricating, so be sure to use the proper amount.

It is also important to regularly calibrate your machine to ensure that it is operating at its best. This involves adjusting the settings and parameters of the machine to ensure that it is sealing boxes and packages correctly. If you are unsure how to calibrate your machine, refer to the manufacturer’s instructions or contact their customer support for assistance.

Regularly replacing worn or damaged parts is another essential maintenance tip for your automated tape around sealing machine. Over time, parts such as cutting blades, rollers, and belts may wear out and need to be replaced. Keeping spare parts on hand can help you quickly address any issues that arise and prevent downtime in your packaging operation.

Lastly, it is important to train your staff on how to properly operate and maintain the machine. Providing proper training can help prevent operator error and ensure that the machine is being used correctly. Encourage your staff to report any issues or concerns they may have with the machine so that they can be addressed promptly.

In conclusion, regular maintenance is essential for keeping your automated tape around sealing machine in top condition. By following these maintenance tips, you can help extend the life of your machine and ensure that it continues to operate efficiently. Remember to clean, inspect, lubricate, calibrate, replace worn parts, and train your staff to keep your machine running smoothly.