Table of Contents

Benefits of Using an Automatic Soft Drink Round Can Seamer Machine

An automatic soft drink round can seamer machine is a valuable piece of equipment for any beverage production facility. This machine is designed to efficiently seal aluminum cans with a lid, ensuring that the contents remain fresh and carbonated. There are several benefits to using an automatic soft drink round can seamer machine, which we will explore in this article.

One of the primary benefits of using an automatic soft drink round can seamer machine is its efficiency. This machine is capable of sealing hundreds of cans per minute, significantly increasing the production output of a beverage facility. By automating the can sealing process, companies can save time and labor costs, allowing them to focus on other aspects of their business.

In addition to its efficiency, an automatic soft drink round can seamer machine also ensures a consistent seal on each can. This is crucial for maintaining the quality and freshness of the beverage inside. With manual sealing methods, there is a risk of human error, which can lead to leaks or improperly sealed cans. By using an automatic seamer machine, companies can guarantee that every can is sealed correctly, reducing the likelihood of product spoilage.

Another benefit of using an automatic soft drink round can seamer machine is its versatility. These machines are designed to work with a variety of can sizes, making them suitable for a wide range of beverage products. Whether a company produces soda, energy drinks, or sparkling water, an automatic seamer machine can accommodate their needs. This versatility allows companies to streamline their production process and adapt to changing market demands.

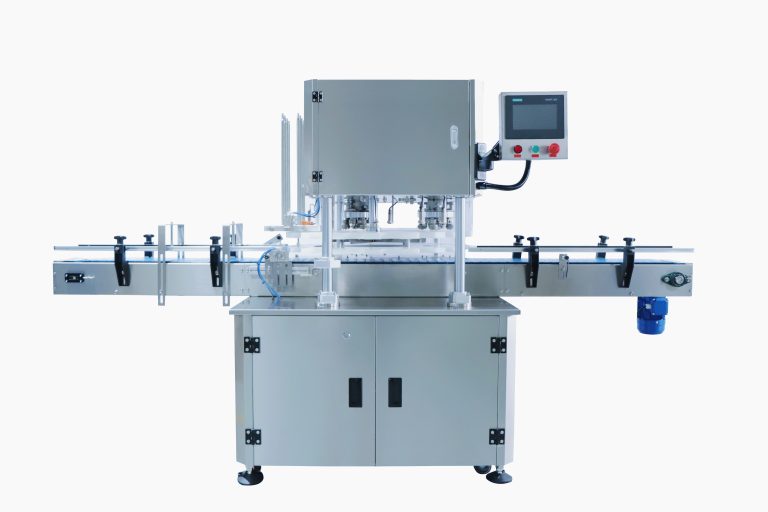

Furthermore, an automatic soft drink round can seamer machine is easy to operate and maintain. Most machines come with user-friendly controls and can be easily adjusted to accommodate different can sizes. Additionally, these machines are built to withstand the rigors of continuous use, requiring minimal maintenance to keep them running smoothly. This makes them a cost-effective investment for beverage companies looking to improve their production efficiency.

Using an automatic soft drink round can seamer machine can also improve the overall safety of a beverage production facility. By automating the can sealing process, companies can reduce the risk of workplace injuries associated with manual sealing methods. This not only protects employees but also helps companies maintain a safe and compliant work environment.

In conclusion, an automatic soft drink round can seamer machine offers numerous benefits for beverage companies looking to improve their production efficiency and product quality. From increased output and consistency to versatility and ease of operation, these machines are a valuable asset for any beverage production facility. By investing in an automatic seamer machine, companies can streamline their production process, reduce labor costs, and ensure the freshness and quality of their products.

How to Choose the Right Automatic Soft Drink Round Can Seamer Machine for Your Business

In the world of beverage production, efficiency and consistency are key factors in ensuring a successful business. When it comes to sealing cans of soft drinks, an automatic can seamer machine is an essential piece of equipment that can streamline the packaging process and maintain the quality of the product. With the market flooded with various options, choosing the right automatic soft drink round can seamer machine for your business can be a daunting task. In this article, we will discuss the factors to consider when selecting a can seamer machine that best suits your needs.

First and foremost, it is important to consider the production capacity of the can seamer machine. Different machines have different output capacities, ranging from a few hundred cans per hour to several thousand cans per hour. Assessing your production needs and volume is crucial in determining the appropriate machine size for your business. Investing in a machine with a higher capacity than needed can lead to unnecessary costs, while a machine with a lower capacity may not be able to keep up with demand.

Another important factor to consider is the size and type of cans that the machine can handle. Can seamer machines come in various sizes to accommodate different can diameters and heights. It is essential to choose a machine that is compatible with the cans used in your production line to ensure a seamless operation. Additionally, consider the material of the cans, as some machines are designed specifically for aluminum cans, while others can handle both aluminum and tinplate cans.

The sealing quality of the can seamer machine is also a critical factor to consider. The integrity of the seal is crucial in preserving the freshness and carbonation of the soft drinks. Look for machines that offer consistent and reliable sealing performance to avoid leaks or contamination. Some machines come with adjustable settings to customize the sealing pressure and speed, allowing for optimal sealing results.

Furthermore, consider the ease of operation and maintenance of the can seamer machine. A user-friendly machine with intuitive controls and easy access for cleaning and maintenance can save time and reduce downtime. Look for machines that come with clear instructions and support from the manufacturer to ensure smooth operation.

Lastly, consider the overall cost of the can seamer machine, including the initial purchase price, installation, and ongoing maintenance costs. While it may be tempting to opt for a cheaper machine, it is important to weigh the upfront costs against the long-term benefits and reliability of the machine. Investing in a high-quality machine from a reputable manufacturer may cost more initially but can save money in the long run by reducing downtime and maintenance costs.

In conclusion, choosing the right automatic soft drink round can seamer machine for your business requires careful consideration of factors such as production capacity, can size compatibility, sealing quality, ease of operation, and overall cost. By evaluating these factors and selecting a machine that meets your specific needs, you can ensure a smooth and efficient packaging process that maintains the quality of your soft drinks.

-768x512.jpg)