Inhoudsopgave

Benefits of Automating the Canning Pickle Packing Production Line

In the world of food production, efficiency and consistency are key factors in ensuring a successful operation. One area where automation can greatly benefit a production line is in the canning pickle packing process. By automating this process, companies can experience a wide range of benefits that can ultimately lead to increased productivity and profitability.

One of the primary benefits of automating the canning pickle packing production line is the ability to increase production output. With automated equipment, companies can pack pickles at a much faster rate than manual labor alone. This means that more pickles can be processed and packaged in a shorter amount of time, allowing companies to meet the demands of their customers more efficiently.

Additionally, automation can help to improve the overall quality of the pickles being packed. Automated equipment is designed to handle pickles with care, ensuring that they are not damaged or bruised during the packing process. This can result in a higher quality product that is more visually appealing to consumers. In addition, automation can help to reduce the risk of contamination, as the equipment is designed to meet strict hygiene standards and can help to minimize the risk of human error.

Another benefit of automating the canning pickle packing production line is the ability to reduce labor costs. By replacing manual labor with automated equipment, companies can save on labor expenses and reallocate resources to other areas of the business. This can help to improve overall efficiency and profitability, as companies can focus on growing their business rather than spending time and resources on manual labor.

Automation can also help to improve workplace safety. Manual labor in a canning pickle packing production line can be physically demanding and repetitive, leading to an increased risk of injury for workers. By automating the process, companies can reduce the physical strain on workers and create a safer working environment. This can help to improve employee morale and reduce the risk of workplace accidents.

In addition to these benefits, automating the canning pickle packing production line can also help to improve overall efficiency and consistency. Automated equipment is designed to perform tasks with precision and accuracy, ensuring that each pickle is packed in the same way every time. This can help to reduce waste and improve overall product quality, leading to increased customer satisfaction.

Overall, automating the canning pickle packing production line can provide a wide range of benefits for companies in the food production industry. From increased production output and improved product quality to reduced labor costs and improved workplace safety, automation can help companies to streamline their operations and improve overall efficiency. By investing in automated equipment, companies can position themselves for long-term success in a competitive market.

How to Optimize Efficiency in a Canning Pickle Packing Production Line

Canning pickle packing production lines are essential for efficiently packaging pickles for distribution and sale. To ensure that these production lines are operating at peak efficiency, it is important to optimize every aspect of the process. From the initial preparation of the pickles to the final packaging and labeling, there are several key steps that can be taken to streamline the production line and increase productivity.

One of the first steps in optimizing efficiency in a canning pickle packing production line is to carefully plan and organize the workflow. This includes determining the most efficient layout for the production line, as well as establishing clear procedures for each step of the process. By carefully planning the workflow, it is possible to minimize downtime and reduce the risk of errors or bottlenecks in the production line.

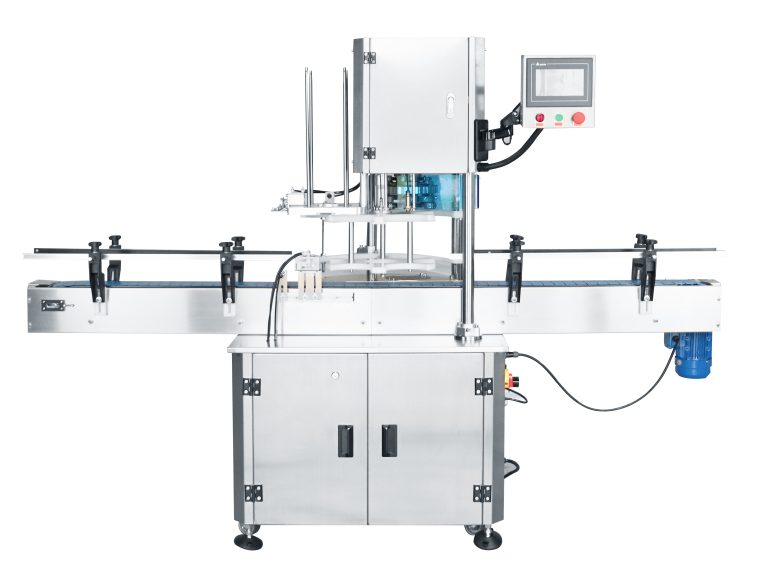

Another important aspect of optimizing efficiency in a canning pickle packing production line is to invest in high-quality equipment and technology. This includes using automated machinery for tasks such as filling jars, sealing lids, and labeling packages. By investing in modern equipment, it is possible to increase the speed and accuracy of the production line, while also reducing the need for manual labor.

In addition to investing in high-quality equipment, it is also important to regularly maintain and calibrate the machinery used in the production line. This includes conducting routine inspections and repairs to ensure that the equipment is operating at peak efficiency. By maintaining the machinery in good working order, it is possible to prevent breakdowns and minimize downtime in the production line.

Another key factor in optimizing efficiency in a canning pickle packing production line is to carefully monitor and analyze the production process. This includes tracking key performance indicators such as production output, downtime, and error rates. By closely monitoring these metrics, it is possible to identify areas where improvements can be made and take corrective action to increase efficiency.

One effective way to optimize efficiency in a canning pickle packing production line is to implement lean manufacturing principles. This includes eliminating waste, reducing unnecessary steps in the production process, and continuously improving the workflow. By applying lean manufacturing principles, it is possible to increase productivity, reduce costs, and improve overall efficiency in the production line.

Finally, it is important to regularly review and update the procedures and protocols used in the canning pickle packing production line. This includes training employees on best practices, implementing new technologies and techniques, and continuously seeking ways to improve the efficiency of the production line. By staying proactive and continuously seeking ways to optimize the production process, it is possible to ensure that the canning pickle packing production line is operating at peak efficiency.

In conclusion, optimizing efficiency in a canning pickle packing production line is essential for maximizing productivity and reducing costs. By carefully planning the workflow, investing in high-quality equipment, maintaining machinery, monitoring performance metrics, implementing lean manufacturing principles, and continuously seeking ways to improve the production process, it is possible to streamline the production line and increase efficiency. By taking these steps, it is possible to ensure that the canning pickle packing production line is operating at peak efficiency and delivering high-quality products to customers.