Inhoudsopgave

Benefits of Using an Automatic Cranberry Plastic Box Taping Sealing Machine

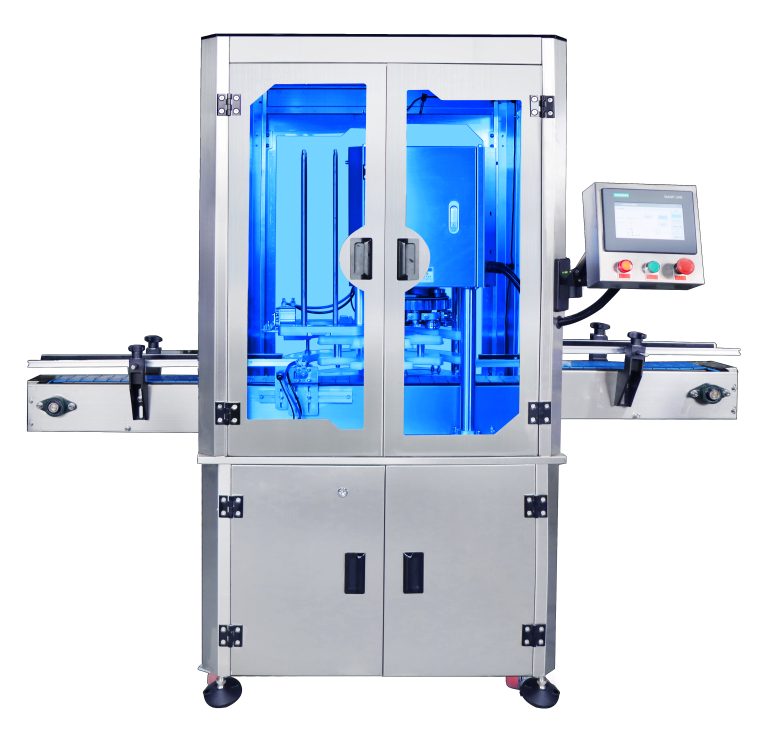

An automatic cranberry plastic box taping sealing machine is a valuable piece of equipment for businesses in the food packaging industry. This machine offers numerous benefits that can help streamline operations, improve efficiency, and ensure the quality of the final product. In this article, we will explore some of the key advantages of using an automatic cranberry plastic box taping sealing machine.

One of the primary benefits of using an automatic cranberry plastic box taping sealing machine is the speed and efficiency it offers. These machines are designed to quickly and accurately seal plastic boxes, saving valuable time and labor costs. With an automatic machine, workers can focus on other tasks while the machine handles the sealing process. This can help increase overall productivity and output, allowing businesses to meet customer demands more effectively.

In addition to speed and efficiency, automatic cranberry plastic box taping sealing machines also offer consistent and reliable sealing results. These machines are programmed to apply the perfect amount of pressure and heat to create a secure seal every time. This helps ensure the quality and integrity of the packaging, reducing the risk of leaks or contamination. Consistent sealing also helps maintain the freshness and shelf life of the cranberries, which is essential for food safety and customer satisfaction.

Another benefit of using an automatic cranberry plastic box taping sealing machine is the cost savings it can provide. While the initial investment in a machine may seem significant, the long-term savings in labor costs and reduced waste can quickly offset this expense. By automating the sealing process, businesses can reduce the need for manual labor and minimize the risk of human error. This can lead to lower production costs and higher profitability in the long run.

Furthermore, automatic cranberry plastic box taping sealing machines are versatile and adaptable to different packaging needs. These machines can be easily adjusted to accommodate various box sizes and sealing requirements, making them suitable for a wide range of products. Whether packaging small or large quantities of cranberries, businesses can rely on these machines to deliver consistent and professional results every time.

In conclusion, the benefits of using an automatic cranberry plastic box taping sealing machine are clear. From increased speed and efficiency to consistent sealing results and cost savings, these machines offer a range of advantages that can help businesses in the food packaging industry thrive. By investing in an automatic sealing machine, businesses can improve their operations, enhance product quality, and ultimately, boost their bottom line.

How to Choose the Right Automatic Cranberry Plastic Box Taping Sealing Machine for Your Business

When it comes to packaging products, especially perishable items like cranberries, it is essential to ensure that they are properly sealed to maintain their freshness and quality. One way to achieve this is by using an automatic cranberry plastic box taping sealing machine. These machines are designed to efficiently seal plastic boxes containing cranberries, providing a secure and airtight seal that helps to extend the shelf life of the product.

There are several factors to consider when choosing the right automatic cranberry plastic box taping sealing machine for your business. One of the most important considerations is the size and capacity of the machine. You will need to determine the volume of cranberries that you will be packaging on a daily basis to ensure that the machine you choose can handle the workload. It is also important to consider the speed at which the machine can operate, as this will impact the efficiency of your packaging process.

Another important factor to consider is the type of sealing mechanism used by the machine. There are several different types of sealing mechanisms available, including heat sealing, pressure sealing, and ultrasonic sealing. Each type of sealing mechanism has its own advantages and disadvantages, so it is important to choose the one that best suits your needs.

In addition to the size, capacity, and sealing mechanism of the machine, you should also consider the overall build quality and durability of the machine. A high-quality machine will be able to withstand the rigors of daily use and provide consistent and reliable sealing results. It is also important to consider the maintenance requirements of the machine, as regular maintenance is essential to ensure that the machine continues to operate efficiently.

When choosing an automatic cranberry plastic box taping sealing machine, it is also important to consider the level of automation that you require. Some machines are fully automated, requiring minimal human intervention, while others may require more manual input. The level of automation that you choose will depend on your specific packaging needs and the level of expertise of your staff.

It is also important to consider the cost of the machine, including both the initial purchase price and any ongoing maintenance costs. While it may be tempting to choose a cheaper machine to save money, it is important to consider the long-term costs and benefits of investing in a higher-quality machine.

In conclusion, choosing the right automatic cranberry plastic box taping sealing machine for your business is a crucial decision that can have a significant impact on the efficiency and effectiveness of your packaging process. By considering factors such as size, capacity, sealing mechanism, build quality, automation level, and cost, you can ensure that you choose a machine that meets your specific needs and helps to enhance the quality and freshness of your cranberry products.