Inhoudsopgave

Benefits of Using an Automatic Nitrogen Gas Can Sealing Machine for Packaging Raisins, Pistachios, Melon Seeds, and Dried Fruit

In the food packaging industry, ensuring the freshness and quality of products is of utmost importance. This is especially true for products like raisins, pistachios, melon seeds, and dried fruit, which are prone to spoilage if not properly sealed. One of the most effective ways to preserve the freshness of these products is by using an automatic nitrogen gas can sealing machine.

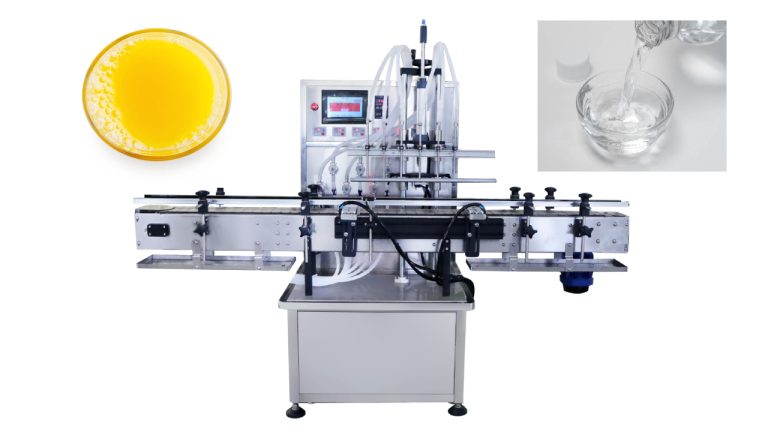

Nitrogen gas is an inert gas that is commonly used in food packaging to displace oxygen. By replacing the oxygen in the packaging with nitrogen gas, the shelf life of the product can be significantly extended. This is because oxygen is a major contributor to the spoilage of food products, as it promotes the growth of bacteria and other microorganisms. By removing oxygen from the packaging, the growth of these harmful organisms is inhibited, thus preserving the freshness and quality of the product.

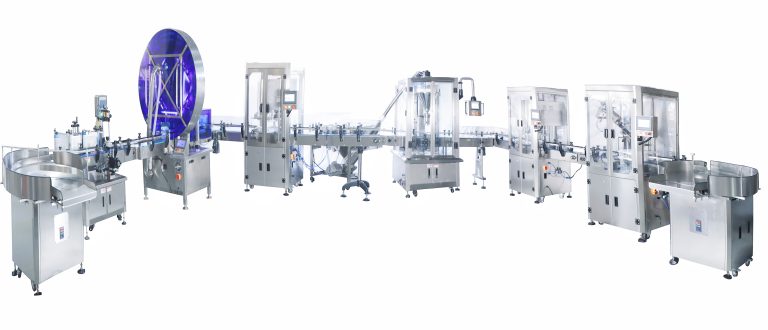

An automatic nitrogen gas can sealing machine is a highly efficient and reliable way to package products like raisins, pistachios, melon seeds, and dried fruit. These machines are designed to automatically seal cans with nitrogen gas, ensuring that the products inside are protected from oxygen and other contaminants. This not only helps to extend the shelf life of the products but also helps to maintain their flavor, texture, and nutritional value.

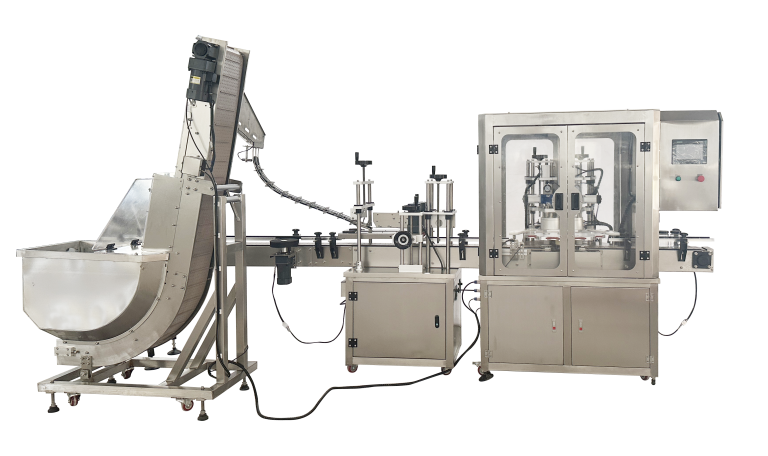

One of the key benefits of using an automatic nitrogen gas can sealing machine is the consistency and precision it offers. These machines are programmed to seal cans with the exact amount of nitrogen gas needed to create an optimal packaging environment. This ensures that each can is sealed to the same high standard, regardless of the operator or production line. This level of consistency is crucial in the food packaging industry, where even small variations in packaging can have a significant impact on the quality and shelf life of the product.

Another benefit of using an automatic nitrogen gas can sealing machine is the speed and efficiency it offers. These machines are capable of sealing hundreds of cans per minute, making them ideal for high-volume production environments. This not only helps to increase productivity and reduce labor costs but also ensures that products are packaged quickly and efficiently, minimizing the risk of contamination or spoilage.

In addition to preserving the freshness and quality of products, using an automatic nitrogen gas can sealing machine can also help to enhance the visual appeal of the packaging. By removing oxygen from the packaging, the risk of oxidation and discoloration of the product is greatly reduced. This helps to maintain the vibrant colors and natural appearance of the products, making them more visually appealing to consumers.

Overall, the benefits of using an automatic nitrogen gas can sealing machine for packaging raisins, pistachios, melon seeds, and dried fruit are clear. From extending shelf life and preserving freshness to increasing efficiency and enhancing visual appeal, these machines offer a range of advantages for food manufacturers and producers. By investing in this technology, companies can ensure that their products are packaged to the highest standard, providing consumers with high-quality, fresh, and delicious products every time.

How to Choose the Right Automatic Nitrogen Gas Can Sealing Machine for Your Packaging Needs

When it comes to packaging perishable goods such as raisins, pistachios, melon seeds, and dried fruit, ensuring that the products remain fresh and free from contaminants is crucial. One of the most effective ways to achieve this is by using an automatic nitrogen gas can sealing machine. These machines are designed to create a hermetic seal on cans by flushing them with nitrogen gas before sealing, which helps to preserve the quality and shelf life of the products inside.

There are several factors to consider when choosing the right automatic nitrogen gas can sealing machine for your packaging needs. The first thing to consider is the size and capacity of the machine. Depending on the volume of products you need to package, you will need to choose a machine that can handle the workload efficiently. It is important to select a machine that can keep up with your production demands without compromising on the quality of the seal.

Another important factor to consider is the level of automation of the machine. Some machines are fully automatic, meaning they require minimal human intervention, while others may require more manual input. Depending on your production process and the level of expertise of your staff, you will need to choose a machine that aligns with your operational requirements.

Additionally, it is important to consider the speed and efficiency of the machine. A faster machine can help increase productivity and reduce downtime, ultimately leading to cost savings and improved efficiency. However, it is important to strike a balance between speed and quality to ensure that the seals are properly formed and the products are adequately protected.

Furthermore, the quality of the seal is a critical factor to consider when choosing an automatic nitrogen gas can sealing machine. A good quality seal is essential for preserving the freshness and quality of the products inside the cans. Look for machines that are equipped with advanced sealing technology to ensure a strong and reliable seal every time.

In addition to the seal quality, it is important to consider the level of nitrogen gas flushing that the machine can provide. Nitrogen gas flushing helps to displace oxygen inside the cans, which can help prevent oxidation and spoilage of the products. Look for machines that offer customizable nitrogen gas flushing options to ensure that you can tailor the process to meet the specific requirements of your products.

Finally, consider the overall reliability and durability of the machine. Investing in a high-quality machine that is built to last can help prevent costly breakdowns and maintenance issues down the line. Look for machines that are made from durable materials and are backed by a reputable manufacturer with a track record of producing reliable equipment.

In conclusion, choosing the right automatic nitrogen gas can sealing machine for your packaging needs is essential for ensuring the freshness and quality of your perishable goods. Consider factors such as size, capacity, automation level, speed, seal quality, nitrogen gas flushing capabilities, and overall reliability when making your decision. By selecting a machine that meets your specific requirements, you can improve efficiency, reduce waste, and ultimately enhance the overall quality of your packaged products.