Inhoudsopgave

Creative Cereal Recipes to Try at Home

Cereals are a staple breakfast food for many people around the world. They are quick, convenient, and can be a healthy option when paired with the right ingredients. However, store-bought cereals can sometimes be lacking in flavor or freshness. That’s where a Cans filling seaming machine can come in handy for creating your own custom cereal blends at home.

With a Cans filling seaming machine, you can easily fill and seal cans with your favorite cereal mixtures. This allows you to control the ingredients and flavors in your cereal, ensuring that you are getting a fresh and delicious breakfast every morning. Plus, making your own cereal can be a fun and creative way to experiment with different flavors and textures.

One creative cereal recipe to try at home is a tropical fruit and nut blend. Start by mixing together your favorite dried fruits such as mango, pineapple, and coconut flakes. Add in some nuts like almonds, cashews, and macadamia nuts for added crunch and protein. Fill your cans with this mixture and seal them with the Cans filling seaming machine for a tasty and nutritious breakfast option.

Another fun cereal recipe to try is a chocolate and peanut butter mix. Combine chocolate-flavored cereal with peanut butter chips, mini marshmallows, and chopped peanuts for a sweet and savory blend that is sure to satisfy your cravings. Fill your cans with this mixture and seal them with the Cans filling seaming machine for a delicious and indulgent breakfast treat.

If you’re looking for a healthier option, try making a granola and dried fruit cereal. Mix together oats, honey, cinnamon, and dried fruits like cranberries, raisins, and apricots. Bake the mixture in the oven until it is golden brown and crispy. Fill your cans with this homemade granola and seal them with the Cans filling seaming machine for a wholesome and satisfying breakfast option.

One of the great things about using a Cans filling seaming machine for your homemade cereals is that you can customize the portion sizes to fit your needs. Whether you prefer a small can for a quick snack or a larger can for a hearty breakfast, the machine allows you to fill and seal cans of various sizes with ease.

In addition to creating your own custom cereal blends, a Cans filling seaming machine can also be used for packaging other dry goods such as nuts, seeds, and snacks. This versatile machine is a great investment for anyone looking to take their food packaging to the next level.

Overall, using a Cans filling seaming machine for creating your own cereal blends at home is a fun and creative way to ensure that you are getting a fresh and delicious breakfast every morning. Experiment with different flavors and ingredients to find the perfect blend that suits your taste preferences. With this machine, the possibilities are endless for creating unique and tasty cereal options that will keep you coming back for more.

The Benefits of Investing in a Can Filling Seaming Machine

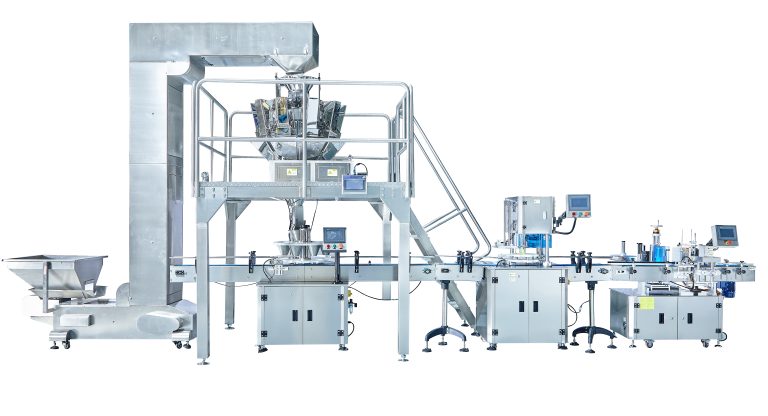

In the food packaging industry, efficiency and precision are key factors in ensuring the quality and safety of products. One essential piece of equipment that can greatly improve the production process is a can filling seaming machine. This machine is specifically designed to fill cans with various food products, such as cereals, and seal them with a tight and secure seam. Investing in a can filling seaming machine can offer a wide range of benefits for food manufacturers, including increased productivity, improved product quality, and reduced labor costs.

One of the primary benefits of investing in a can filling seaming machine is the significant increase in productivity that it can provide. These machines are capable of filling and sealing hundreds of cans per minute, far surpassing the speed and efficiency of manual labor. This means that manufacturers can produce a larger volume of products in a shorter amount of time, leading to increased output and ultimately, higher profits. Additionally, the consistent and precise filling and sealing process of the machine ensures that each can is filled to the exact same level and sealed with the same level of tightness, resulting in a uniform and professional-looking final product.

Another key benefit of using a can filling seaming machine is the improvement in product quality that it can offer. These machines are equipped with advanced technology that allows for precise control over the filling and sealing process, ensuring that each can is filled with the correct amount of product and sealed with a tight and secure seam. This helps to prevent product spillage, contamination, and spoilage, ultimately leading to a higher quality end product that is safe for consumers to consume. Additionally, the airtight seal created by the machine helps to preserve the freshness and flavor of the product, extending its shelf life and reducing the likelihood of waste.

In addition to increased productivity and improved product quality, investing in a can filling seaming machine can also lead to significant cost savings for food manufacturers. By automating the filling and sealing process, manufacturers can reduce their reliance on manual labor, which can be costly and time-consuming. This can help to lower labor costs and increase overall efficiency, allowing manufacturers to produce more products in less time and with fewer resources. Additionally, the precise control and consistency provided by the machine can help to reduce product waste and minimize the risk of costly errors or defects, further contributing to cost savings in the long run.

Overall, investing in a can filling seaming machine can offer a wide range of benefits for food manufacturers, including increased productivity, improved product quality, and reduced labor costs. These machines are essential for ensuring the efficient and precise packaging of food products, such as cereals, and can help manufacturers to streamline their production process and deliver high-quality products to consumers. By investing in a can filling seaming machine, manufacturers can stay ahead of the competition, meet the demands of the market, and ultimately, achieve greater success in the food packaging industry.