Inhoudsopgave

Benefits of Using a Composite Cans Sealer Manual

Composite cans are a popular packaging option for a wide range of products, from snacks to powders to household items. These cylindrical containers are made of multiple layers of materials, such as paperboard, aluminum foil, and plastic, which provide excellent protection and durability. To ensure that these cans are properly sealed, a composite cans sealer manual is essential.

One of the key benefits of using a composite cans sealer manual is the ability to achieve a consistent and secure seal on each can. Manual sealing machines allow operators to adjust the settings to ensure that the cans are sealed tightly and securely, preventing any leaks or contamination. This level of control is crucial for maintaining the quality and integrity of the products inside the cans.

In addition to ensuring a secure seal, a composite cans sealer manual also offers flexibility in terms of the types of cans that can be sealed. These machines can accommodate a variety of can sizes and shapes, making them suitable for a wide range of products. Whether you are packaging small snack items or larger household products, a composite cans sealer manual can be adjusted to meet your specific needs.

Another benefit of using a composite cans sealer manual is the cost-effectiveness of manual sealing machines compared to automated options. While automated machines may offer higher speeds and efficiency, they can also come with a higher price tag. Manual sealing machines are a more affordable option for small to medium-sized businesses looking to seal composite cans without breaking the bank.

Furthermore, manual sealing machines are easy to operate and require minimal training for operators. With simple controls and clear instructions, anyone can quickly learn how to use a composite cans sealer manual to seal cans effectively. This ease of use makes manual sealing machines a practical choice for businesses with limited resources or personnel.

Additionally, manual sealing machines are compact and portable, making them ideal for businesses with limited space or those that need to move their packaging operations to different locations. These machines can be easily transported and set up wherever they are needed, providing flexibility and convenience for businesses on the go.

Overall, the benefits of using a composite cans sealer manual are clear. From achieving a consistent and secure seal to accommodating a variety of can sizes and shapes, manual sealing machines offer a cost-effective and practical solution for businesses looking to package their products in composite cans. With easy operation, flexibility, and portability, manual sealing machines are a valuable tool for businesses of all sizes.

Step-by-Step Guide on How to Seal Composite Cans Manually

Composite cans are a popular packaging option for a variety of products, from snacks to powders to household items. These cylindrical containers are made of multiple layers of materials, such as paperboard, foil, and plastic, to provide durability and protection for the contents inside. One crucial step in the production process of composite cans is sealing them to ensure that the products remain fresh and secure during storage and transportation.

Sealing composite cans manually can be a cost-effective and efficient way for small-scale manufacturers or businesses to package their products. In this article, we will provide a step-by-step guide on how to seal composite cans manually using a composite cans sealer.

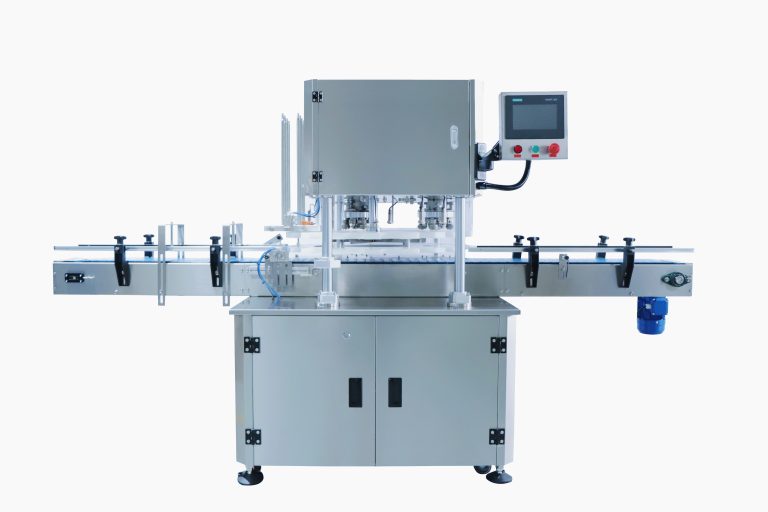

The first step in sealing composite cans manually is to prepare the cans and the sealer. Make sure that the composite cans are filled with the desired product and that the lids are securely in place. Next, set up the composite cans sealer according to the manufacturer’s instructions. This may involve adjusting the settings for the can size and the sealing temperature.

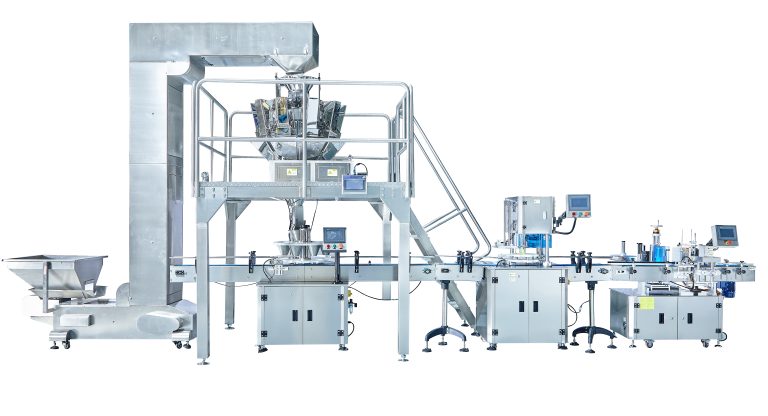

Once the sealer is set up, place the filled composite cans on the conveyor belt or platform of the sealer. Make sure that the cans are evenly spaced and aligned properly to ensure a consistent seal. Start the sealer according to the manufacturer’s instructions, and the sealing process will begin.

As the cans move through the sealer, the heat from the sealing element will melt the plastic layer of the can’s lid, creating a tight seal between the lid and the body of the can. The pressure from the sealer will also help to ensure that the seal is secure and airtight.

After the cans have passed through the sealer, allow them to cool before handling them. This will help to prevent any damage to the seal and ensure that the cans are ready for storage or shipment. Once the cans have cooled, inspect them to ensure that the seals are intact and that there are no leaks or defects.

If any cans have not been properly sealed, you may need to reseal them using the sealer. Make sure to adjust the settings as needed and carefully monitor the sealing process to ensure a successful seal.

Sealing composite cans manually can be a straightforward process with the right equipment and attention to detail. By following these steps and taking the time to properly set up and monitor the sealing process, you can ensure that your products are securely packaged and ready for distribution.

In conclusion, sealing composite cans manually is a practical and efficient way to package products for small-scale manufacturers or businesses. By following the step-by-step guide provided in this article, you can confidently seal composite cans using a composite cans sealer. Remember to carefully prepare the cans and the sealer, monitor the sealing process, and inspect the sealed cans for quality assurance. With practice and attention to detail, you can master the art of sealing composite cans manually and ensure that your products reach customers in top condition.

Maintenance Tips for Keeping Your Composite Cans Sealer Manual in Top Condition

Composite cans sealers are essential machines in the packaging industry, used to seal composite cans securely and efficiently. To ensure that your composite cans sealer manual operates at its best, regular maintenance is crucial. By following these maintenance tips, you can keep your composite cans sealer manual in top condition and prolong its lifespan.

One of the most important maintenance tasks for your composite cans sealer manual is regular cleaning. Dust, debris, and adhesive residue can build up on the machine over time, affecting its performance. To clean your sealer manual, start by unplugging the machine and allowing it to cool down. Use a soft cloth or brush to remove any dirt or debris from the exterior and interior of the machine. Be sure to pay special attention to the sealing mechanism and rollers, as these are the parts most prone to buildup.

In addition to cleaning, it is essential to regularly inspect the components of your composite cans sealer manual for any signs of wear or damage. Check the sealing mechanism, rollers, belts, and other moving parts for any cracks, tears, or misalignments. If you notice any issues, it is important to address them promptly to prevent further damage to the machine. Replace any worn or damaged parts as needed to ensure that your sealer manual continues to operate smoothly.

Another important maintenance task for your composite cans sealer manual is lubrication. Proper lubrication of the moving parts of the machine helps reduce friction and wear, prolonging the lifespan of the components. Refer to the manufacturer’s guidelines for the type of lubricant to use and the recommended schedule for lubrication. Be sure to apply the lubricant sparingly and wipe away any excess to prevent buildup.

Regular calibration of your composite cans sealer manual is also essential to ensure accurate and consistent sealing. Over time, the settings on the machine may drift, affecting the quality of the seals. Use a calibration tool to check the temperature, pressure, and speed settings of the sealer manual and make any necessary adjustments. Regular calibration helps maintain the quality of the seals and prevents costly rework or product waste.

In addition to these maintenance tasks, it is important to follow proper operating procedures when using your composite cans sealer manual. Avoid overloading the machine or running it at speeds higher than recommended, as this can cause excessive wear and damage. Always use the correct size and type of composite cans for the machine, and ensure that they are properly aligned and positioned for sealing.

By following these maintenance tips, you can keep your composite cans sealer manual in top condition and ensure that it continues to operate efficiently and effectively. Regular cleaning, inspection, lubrication, calibration, and proper operating procedures are essential for prolonging the lifespan of your sealer manual and maintaining the quality of your sealed composite cans. With proper maintenance, your composite cans sealer manual will continue to provide reliable sealing performance for years to come.