Inhoudsopgave

Understanding the Efficiency of Double Head Servo Capping Machines for Bottles and Jars

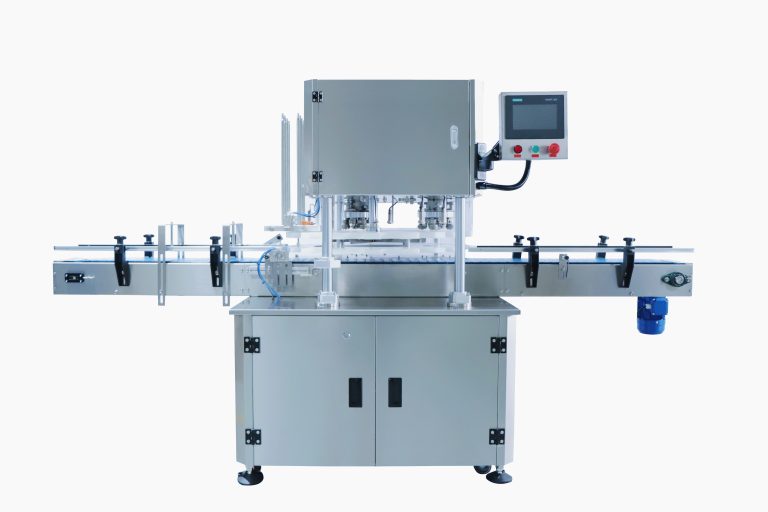

The double head servo capping machine for bottles and jars is a revolutionary piece of equipment that has significantly transformed the packaging industry. This machine, designed with precision and efficiency in mind, has become an indispensable tool for businesses that require high-speed capping of bottles and jars.

The double head servo capping machine operates on a simple yet effective principle. It uses two capping heads, hence the name ‘double head’, to cap bottles and jars simultaneously. This dual operation significantly reduces the time taken to cap a single bottle or jar, thereby increasing the overall production speed.

The machine’s efficiency is further enhanced by the use of servo motors. These motors are known for their high precision and speed, which are crucial in the capping process. The servo motors ensure that the caps are screwed onto the bottles or jars accurately and securely, preventing any leakage or spillage. This precision is particularly important in industries such as pharmaceuticals and food and beverage, where product integrity is paramount.

Moreover, the double head servo capping machine is designed to handle a wide range of bottle and jar sizes. This versatility makes it a valuable asset for businesses that deal with various product sizes. The machine’s adjustable settings allow for easy customization to fit different bottle or jar sizes, ensuring a tight and secure cap every time.

Another notable feature of the double head servo capping machine is its user-friendly interface. The machine is easy to operate, with clear instructions and controls that allow for smooth operation. This ease of use reduces the need for extensive training, saving businesses both time and resources.

The double head servo capping machine also boasts of robust construction. Made from high-quality materials, the machine is designed to withstand the rigors of continuous operation. This durability ensures that the machine can deliver consistent performance over a long period, providing businesses with a reliable solution for their capping needs.

In addition to its operational efficiency, the double head servo capping machine also contributes to cost efficiency. By speeding up the capping process, the machine allows businesses to increase their production volumes without a corresponding increase in operational costs. This increased productivity can significantly boost a business’s bottom line.

Furthermore, the machine’s precision in capping reduces wastage caused by improperly capped bottles or jars. This reduction in wastage translates to cost savings, further enhancing the machine’s cost-effectiveness.

In conclusion, the double head servo capping machine for bottles and jars is a highly efficient and cost-effective solution for businesses in the packaging industry. Its ability to cap bottles and jars quickly and accurately, coupled with its versatility and durability, makes it an invaluable tool for businesses looking to optimize their production processes. By investing in a double head servo capping machine, businesses can significantly improve their operational efficiency, reduce wastage, and ultimately, increase their profitability.

Innovations in Packaging: The Role of Double Head Servo Capping Machines in Bottle and Jar Sealing

In the realm of packaging, technological advancements have been instrumental in enhancing efficiency, precision, and productivity. One such innovation that has revolutionized the packaging industry is the double head servo capping machine, specifically designed for sealing bottles and jars. This state-of-the-art equipment has significantly improved the packaging process, ensuring that products are securely sealed, thereby maintaining their quality and freshness.

The double head servo capping machine is a marvel of modern engineering, designed to provide a high degree of accuracy and consistency in the capping process. It employs two servo motors, each controlling a capping head, which work in tandem to apply caps to bottles or jars. The use of servo motors allows for precise control over the torque applied during the capping process, ensuring a perfect seal every time. This level of precision is crucial in the packaging industry, where a poorly sealed product can lead to spoilage, contamination, or leakage, resulting in customer dissatisfaction and potential financial loss.

Moreover, the double head servo capping machine is not only about precision but also about speed. The dual-head design allows for simultaneous capping of two bottles or jars, effectively doubling the machine’s output compared to traditional single-head cappers. This increased productivity is a boon for businesses, allowing them to meet high demand without compromising on the quality of the seal.

The versatility of the double head servo capping machine is another of its standout features. It can handle a wide range of bottle and jar sizes and shapes, making it suitable for various industries, from food and beverage to pharmaceuticals and cosmetics. This adaptability means businesses can use the same machine for different products, saving on equipment costs and space.

Furthermore, the double head servo capping machine is designed with user-friendliness in mind. Its operation is straightforward, requiring minimal training for operators. Additionally, it is equipped with features such as automatic cap sorting and feeding, which further streamline the capping process. The machine’s design also prioritizes safety, with features like emergency stop buttons and protective guards to prevent accidents.

The integration of advanced technology into the double head servo capping machine has also led to enhanced reliability. The use of high-quality components and sophisticated control systems ensures that the machine operates smoothly and with minimal downtime. This reliability translates into lower maintenance costs and higher overall productivity for businesses.

In conclusion, the double head servo capping machine represents a significant leap forward in packaging technology. Its precision, speed, versatility, user-friendliness, and reliability make it an invaluable tool for businesses looking to optimize their packaging processes. As the packaging industry continues to evolve, innovations like the double head servo capping machine will undoubtedly play a pivotal role in shaping its future.