Inhoudsopgave

Advantages of Using Fully Auto Plastic Cover Press Cap Machine

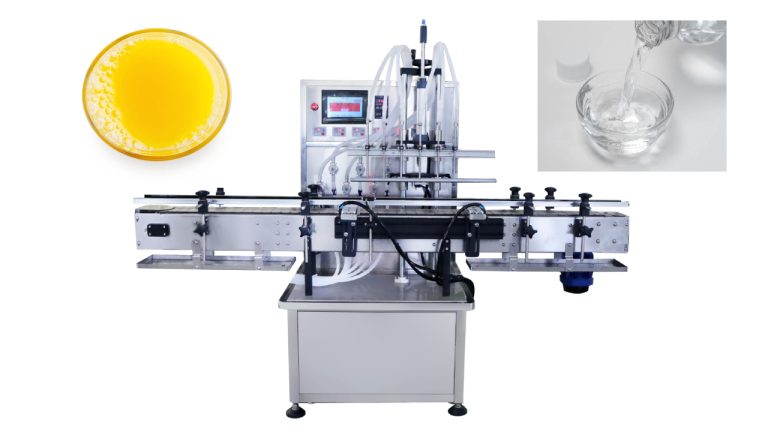

In the manufacturing industry, efficiency and precision are key factors in ensuring the success of a business. One way to achieve this is by utilizing advanced machinery that can streamline production processes and improve overall output. One such machine that has gained popularity in recent years is the fully auto plastic cover press cap machine.

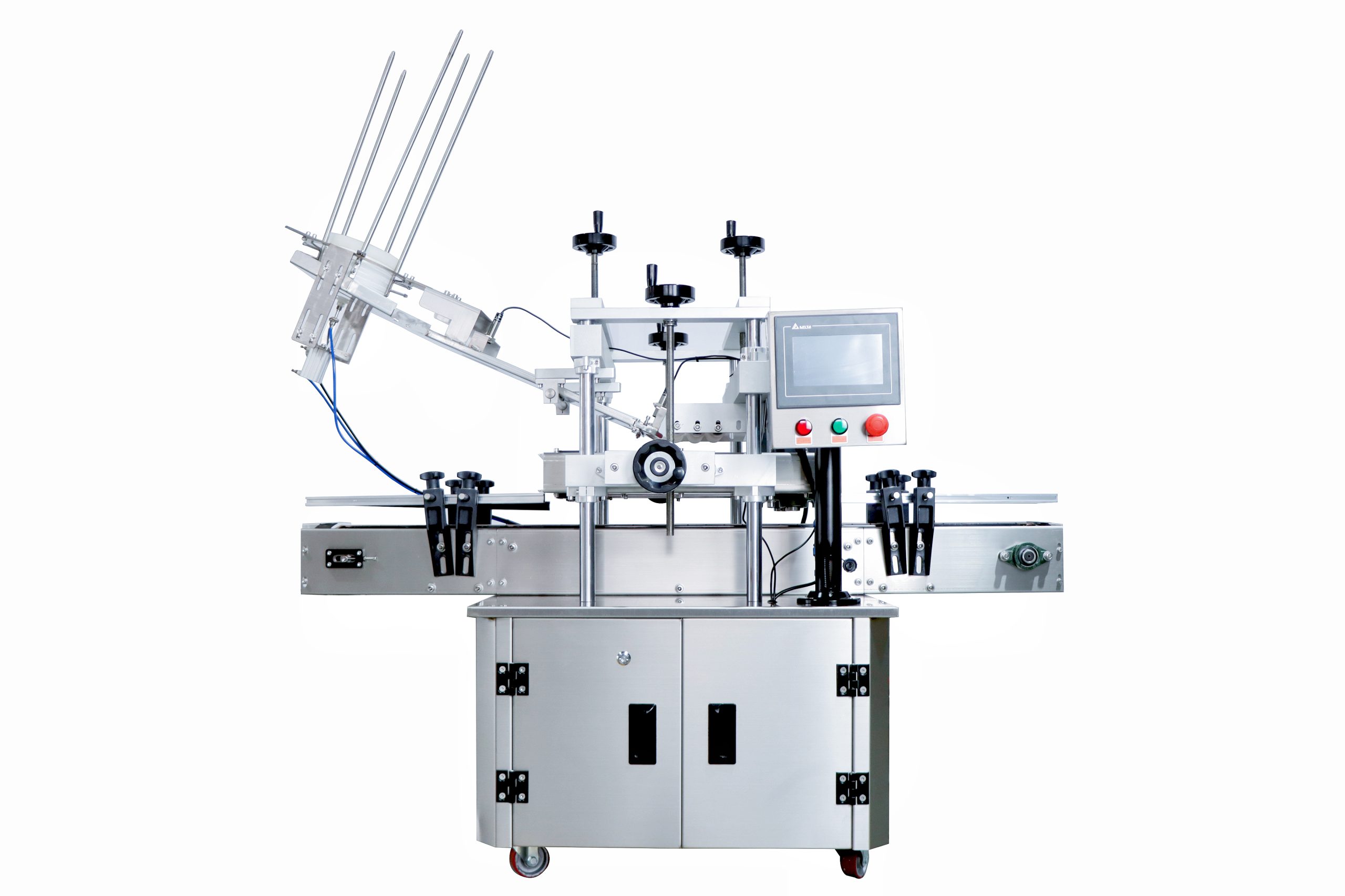

This innovative piece of equipment is designed to automate the process of attaching plastic covers to various products, such as bottles, jars, and containers. By eliminating the need for manual labor, the fully auto plastic cover press cap machine can significantly increase production speed and reduce the risk of human error.

One of the main advantages of using a fully auto plastic cover press cap machine is its ability to consistently apply caps with precision and accuracy. This is especially important in industries where product quality is paramount, such as pharmaceuticals or food and beverage. With a fully automated system, manufacturers can ensure that each cap is applied correctly every time, reducing the likelihood of defects or inconsistencies in the final product.

Furthermore, the fully auto plastic cover press cap machine is capable of handling a wide range of cap sizes and shapes, making it versatile and adaptable to different production needs. This flexibility allows manufacturers to easily switch between different products without the need for extensive retooling or adjustments, saving time and resources in the long run.

Another key advantage of using a fully auto plastic cover press cap machine is its efficiency in terms of labor and cost savings. By automating the cap application process, manufacturers can reduce the need for manual labor, which not only saves on labor costs but also minimizes the risk of injuries or accidents in the workplace. Additionally, the machine’s high-speed capabilities can significantly increase production output, leading to higher overall efficiency and profitability for the business.

In addition to these benefits, the fully auto plastic cover press cap machine also offers improved safety features compared to traditional manual methods. With built-in sensors and safety mechanisms, the machine can detect and prevent potential hazards, such as jams or malfunctions, ensuring a safe working environment for operators and employees.

Overall, the fully auto plastic cover press cap machine is a valuable asset for manufacturers looking to improve their production processes and enhance product quality. With its precision, versatility, efficiency, and safety features, this advanced piece of equipment can help businesses stay competitive in today’s fast-paced market.

In conclusion, the advantages of using a fully auto plastic cover press cap machine are clear. From increased precision and efficiency to cost savings and improved safety, this innovative piece of machinery offers a wide range of benefits for manufacturers across various industries. By investing in this advanced technology, businesses can streamline their production processes, enhance product quality, and ultimately achieve greater success in the marketplace.

How to Choose the Right Fully Auto Plastic Cover Press Cap Machine for Your Business

In today’s fast-paced world, efficiency and productivity are key factors in the success of any business. When it comes to manufacturing plastic cover press caps, having the right equipment can make all the difference. Fully auto plastic cover press cap machines are a popular choice for businesses looking to streamline their production process and increase output. However, with so many options available on the market, choosing the right machine for your business can be a daunting task. In this article, we will discuss some key factors to consider when selecting a fully auto plastic cover press cap machine for your business.

One of the first things to consider when choosing a fully auto plastic cover press cap machine is the production capacity. Different machines have different production capacities, so it’s important to choose one that can meet the demands of your business. Consider factors such as the size of your production runs, the speed at which you need to produce caps, and the number of caps you need to produce per hour. By understanding your production needs, you can choose a machine that will help you meet your goals and maximize efficiency.

Another important factor to consider when choosing a fully auto plastic cover press cap machine is the level of automation. Fully auto machines come in a range of automation levels, from semi-automatic to fully automatic. Fully automatic machines require minimal human intervention, allowing for greater efficiency and productivity. However, they also tend to be more expensive than semi-automatic machines. Consider your budget and production needs when deciding on the level of automation that is right for your business.

In addition to production capacity and automation level, it’s important to consider the quality of the machine. Look for a machine that is built to last and can withstand the demands of a busy production environment. Check the materials used in the construction of the machine, as well as the reputation of the manufacturer. A high-quality machine will not only produce better results but will also require less maintenance and repair, saving you time and money in the long run.

When choosing a fully auto plastic cover press cap machine, it’s also important to consider the features and capabilities of the machine. Look for a machine that offers a range of customization options, such as adjustable speed and pressure settings, to ensure that you can produce caps that meet your specific requirements. Consider whether the machine offers any additional features, such as automatic cap sorting or labeling, that can further streamline your production process.

Finally, consider the support and service options offered by the manufacturer. A fully auto plastic cover press cap machine is a significant investment, so it’s important to choose a manufacturer that offers reliable customer support and service. Look for a manufacturer that offers training and technical support, as well as a warranty on the machine. By choosing a reputable manufacturer with a strong track record of customer satisfaction, you can ensure that your investment is protected and that your production process runs smoothly.

In conclusion, choosing the right fully auto plastic cover press cap machine for your business is a decision that should not be taken lightly. By considering factors such as production capacity, automation level, quality, features, and support options, you can select a machine that will help you maximize efficiency, productivity, and profitability in your business. With the right machine in place, you can streamline your production process, increase output, and stay ahead of the competition in today’s fast-paced market.