Inhoudsopgave

Voordelen van het gebruik van handmatige metalen inblikkende sluitmachines in voedselverpakkingen

Handmatige metalen bliksluitmachines zijn essentiële hulpmiddelen in de voedselverpakkingsindustrie. Deze machines zijn ontworpen om metalen blikken veilig af te sluiten, waardoor de versheid en veiligheid van de producten erin wordt gegarandeerd. In dit artikel bespreken we de voordelen van het gebruik van handmatige metalen bliksluitmachines in voedselverpakkingen.

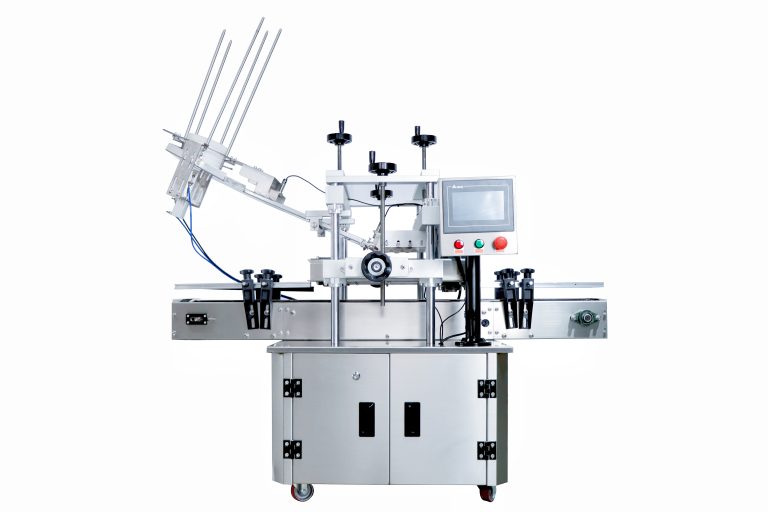

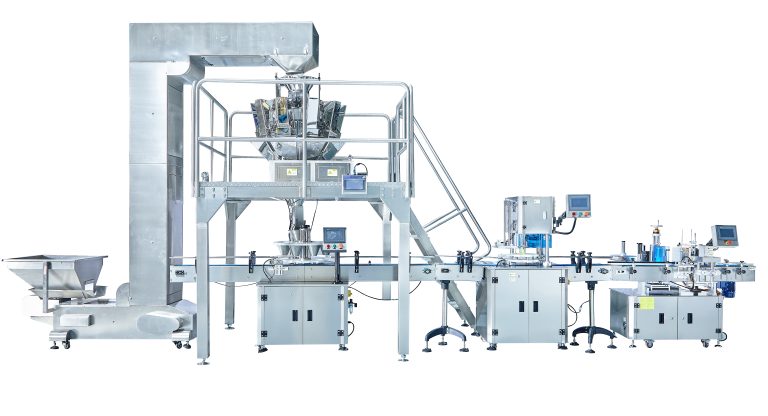

Een van de belangrijkste voordelen van het gebruik van handmatige metalen bliksluitmachines is hun efficiëntie. Deze machines zijn ontworpen om blikjes snel en nauwkeurig te sluiten, waardoor voedselproducenten hun producten sneller kunnen verpakken. Dit kan helpen de productiviteit te verhogen en de productiekosten te verlagen, waardoor handmatige metalen bliksluitmachines een waardevolle investering zijn voor elk voedselverpakkingsbedrijf.

Naast hun efficiëntie bieden handmatige metalen bliksluitmachines ook een hoge mate van precisie. Deze machines zijn ontworpen om blikjes goed en veilig af te sluiten, zodat de inhoud vers en vrij van besmetting blijft. Deze precisie is essentieel voor het behoud van de kwaliteit en veiligheid van voedselproducten, waardoor handmatige metalen bliksluitmachines een onmisbaar hulpmiddel zijn voor voedselproducenten.

Een ander voordeel van het gebruik van handmatige metalen bliksluitmachines is hun veelzijdigheid. Deze machines zijn in staat een breed scala aan blikformaten te sealen, waardoor ze geschikt zijn voor het verpakken van diverse soorten voedselproducten. Of u nu fruit, groenten of vlees verpakt, de handmatige metalen bliksluitmachines kunnen aan uw behoeften voldoen, waardoor ze een veelzijdige en aanpasbare oplossing zijn voor het verpakken van voedsel.

Handmatige metalen bliksluitmachines zijn ook eenvoudig te bedienen en te onderhouden. Deze machines zijn ontworpen met gebruiksvriendelijke bedieningselementen en zijn gebouwd om de ontberingen van het dagelijks gebruik te weerstaan. Met het juiste onderhoud en de juiste verzorging kunnen handmatige metalen bliksluitmachines jarenlang betrouwbare service bieden, waardoor ze een kosteneffectieve oplossing zijn voor voedselverpakkingsactiviteiten.

Bovendien zijn handmatige metalen bliksluitmachines compact en draagbaar, waardoor ze ideaal zijn voor kleine bedrijven. grootschalige voedselverpakkingsactiviteiten. Deze machines kunnen eenvoudig worden verplaatst en op verschillende locaties worden opgesteld, waardoor voedselproducenten hun producten kunnen verpakken waar ze nodig zijn. Deze flexibiliteit kan voedselproducenten helpen aan de eisen van hun klanten te voldoen en hun zakelijke kansen uit te breiden.

Concluderend bieden handmatige metalen bliksluitmachines een reeks voordelen voor voedselverpakkingsactiviteiten. Van hun efficiëntie en precisie tot hun veelzijdigheid en gebruiksgemak: deze machines zijn essentiële hulpmiddelen om de kwaliteit en veiligheid van voedingsproducten te garanderen. Of u nu fruit, groenten of vlees verpakt, handmatige metalen bliksluitmachines kunnen u helpen uw verpakkingsproces te stroomlijnen en aan de behoeften van uw klanten te voldoen. Overweeg vandaag nog om te investeren in een handmatige metalen bliksluitmachine voor uw voedselverpakkingsbedrijf.

Hoe u de juiste fabrikant van handmatige metalen inblikkende sluitmachines voor uw bedrijf kiest

Als het gaat om het kiezen van de juiste fabrikant van handmatige bliksluitmachines voor uw bedrijf, zijn er verschillende factoren waarmee u rekening moet houden. Van de kwaliteit van de machines tot de reputatie van de fabrikant: het maken van de juiste keuze kan een aanzienlijke impact hebben op de efficiëntie en productiviteit van uw activiteiten. In dit artikel bespreken we enkele belangrijke overwegingen waarmee u rekening moet houden bij het selecteren van een fabrikant van handmatige metalen bliksluitmachines.

Een van de eerste dingen waarmee u rekening moet houden bij het kiezen van een fabrikant van handmatige metalen bliksluitmachines is de kwaliteit van hun machines. Het is belangrijk om ervoor te zorgen dat de fabrikant machines produceert die duurzaam, betrouwbaar en gebouwd zijn om lang mee te gaan. Zoek naar fabrikanten die materialen van hoge kwaliteit gebruiken en de reputatie hebben machines te produceren die bestand zijn tegen de ontberingen van dagelijks gebruik in een commerciële omgeving.

Een andere belangrijke factor waarmee u rekening moet houden, is de reputatie van de fabrikant. Zoek naar fabrikanten die een staat van dienst hebben in het produceren van machines van hoge kwaliteit en het bieden van uitstekende klantenservice. Het lezen van recensies en getuigenissen van andere bedrijven die machines van de fabrikant hebben gekocht, kan u waardevol inzicht geven in hun reputatie en de kwaliteit van hun producten.

Naast de kwaliteit en reputatie is het ook belangrijk om rekening te houden met de kosten van de machines. Hoewel het verleidelijk kan zijn om de goedkoopste optie te kiezen, is het belangrijk om te onthouden dat kwaliteit de hoogste prioriteit moet hebben. Investeren in een machine van hoge kwaliteit van een gerenommeerde fabrikant kost misschien meer op voorhand, maar kan u op de lange termijn geld besparen door de uitvaltijd en onderhoudskosten te verminderen.

Bij het kiezen van een fabrikant van handmatige metalen bliksluitmachines is het ook belangrijk om houd rekening met het niveau van klantenondersteuning dat zij bieden. Zoek naar fabrikanten die training en ondersteuning bieden om u te helpen het maximale uit uw machines te halen. Een fabrikant die op uw behoeften inspeelt en tijdig hulp biedt wanneer zich problemen voordoen, kan een groot verschil maken in het succes van uw activiteiten.

Overweeg ten slotte het aanbod aan machines en opties die de fabrikant aanbiedt. Zoek naar een fabrikant die een verscheidenheid aan machines aanbiedt om aan uw specifieke behoeften en vereisten te voldoen. Of u nu een machine nodig heeft voor het sluiten van blikken van verschillende afmetingen of voor verschillende soorten producten, het kiezen van een fabrikant met een gevarieerde productlijn kan ervoor zorgen dat u de juiste machine voor uw bedrijf vindt.

Kortom, het kiezen van de juiste handmatige metalen inblikken fabrikant van sluitmachines voor uw bedrijf is een beslissing die niet lichtvaardig moet worden genomen. Door factoren als kwaliteit, reputatie, kosten, klantenondersteuning en productassortiment in overweging te nemen, kunt u een weloverwogen beslissing nemen waar uw bedrijf op de lange termijn profijt van zal hebben. Neem de tijd om verschillende fabrikanten te onderzoeken en te vergelijken om degene te vinden die het beste aan uw behoeften en eisen voldoet. Met de juiste fabrikant aan uw zijde kunt u de efficiëntie en productiviteit van uw activiteiten verbeteren en uw bedrijf naar een hoger niveau tillen.