Table of Contents

Benefícios do uso da máquina de engarrafamento semiautomática de nozes em pó

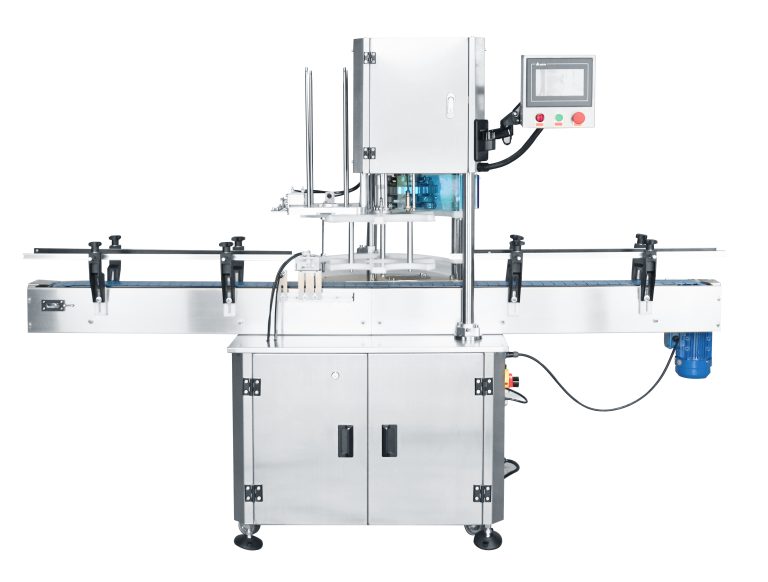

No mundo da fabricação e embalagem, eficiência e precisão são fatores-chave para garantir o sucesso de um negócio. Uma maneira de conseguir isso é utilizar máquinas de envase semiautomáticas, como a máquina de envase semiautomática de garrafas de noz em pó. Esta máquina oferece uma gama de benefícios que podem ajudar a agilizar o processo de produção e melhorar a produtividade geral.

Um dos principais benefícios de usar uma máquina semiautomática de envase de garrafas de pó de noz é sua capacidade de encher garrafas com precisão com a quantidade desejada de pó . Isto é crucial para garantir que cada produto atenda às especificações exigidas e mantenha a consistência em todos os lotes. A máquina está equipada com controles de precisão que permitem ajustes precisos, garantindo que cada garrafa seja preenchida até o nível exato necessário.

Além da precisão, a máquina envasadora semiautomática de garrafas em pó de noz também oferece maior eficiência no processo de produção. Ao automatizar o processo de enchimento, a máquina pode reduzir significativamente o tempo e o trabalho necessários para encher cada garrafa. Isso permite velocidades de produção mais rápidas e maior produção, levando, em última análise, a economia de custos e maior lucratividade para o negócio. Além disso, a máquina semiautomática de envase de garrafas de pó de noz foi projetada para ser fácil de usar e operar. Com controles intuitivos e um processo de configuração simples, os operadores podem aprender rapidamente como usar a máquina de maneira eficaz, reduzindo a necessidade de treinamento extensivo ou de habilidades especializadas. Isso a torna uma solução ideal para empresas que buscam melhorar seus processos de produção sem investir em máquinas complexas ou extensos programas de treinamento.

Outro benefício de usar uma máquina semiautomática de envase de garrafas de nozes em pó é sua versatilidade e flexibilidade. A máquina pode ser facilmente ajustada para acomodar diferentes tamanhos de garrafas e volumes de enchimento, tornando-a adequada para uma ampla gama de produtos e requisitos de embalagem. Essa adaptabilidade permite que as empresas respondam rapidamente às mudanças nas demandas do mercado e personalizem seus processos de produção para atender às necessidades específicas dos clientes. Além disso, a máquina semiautomática de envase de garrafas de nozes em pó foi projetada para ser durável e confiável, garantindo um desempenho consistente ao longo do tempo. Com manutenção regular e cuidados adequados, a máquina pode continuar a operar com eficiência máxima, proporcionando valor a longo prazo para o negócio. Essa confiabilidade ajuda a minimizar o tempo de inatividade e reduzir o risco de reparos ou substituições dispendiosas, aumentando ainda mais a eficiência geral do processo de produção.

No geral, os benefícios de usar uma máquina semiautomática de envase de garrafas de nozes em pó são claros. Desde maior precisão e eficiência até operação e versatilidade fáceis de usar, esta máquina oferece uma série de vantagens que podem ajudar as empresas a otimizar seus processos de produção e alcançar maior sucesso. Ao investir nesta tecnologia, as empresas podem melhorar a sua competitividade, aumentar a produtividade e, em última análise, impulsionar o crescimento e a rentabilidade a longo prazo.

Como escolher a máquina de engarrafamento semiautomática de nozes em pó certa para o seu negócio

Quando se trata de embalar produtos como nozes em pó, ter a máquina de envase de garrafas certa pode fazer uma diferença significativa na eficiência e produtividade do seu negócio. As máquinas semiautomáticas de envase de garrafas em pó de nogueira são uma escolha popular para muitas empresas devido à sua facilidade de uso e economia. Porém, com tantas opções disponíveis no mercado, pode ser um desafio escolher a opção certa para suas necessidades específicas. Neste artigo, discutiremos alguns fatores-chave a serem considerados ao selecionar uma máquina semiautomática de envase de garrafas de nozes em pó para o seu negócio. Uma das primeiras coisas a considerar ao escolher uma máquina semiautomática de envase de garrafas de nozes em pó é a produção capacidade da máquina. A capacidade de produção de uma máquina de envase de garrafas é normalmente medida em termos de garrafas cheias por minuto. É fundamental escolher uma máquina que atenda às demandas do seu negócio sem causar gargalos no processo produtivo. Considere fatores como o tamanho da sua linha de produção, o volume de pó de noz que você precisa encher e a velocidade com que você precisa encher as garrafas.

Outro fator importante a considerar é a exatidão e precisão da máquina de envase. A precisão da máquina determinará a consistência dos níveis de enchimento em cada garrafa, o que é crucial para manter a qualidade do produto e atender aos padrões regulatórios. Procure uma máquina que ofereça controle preciso sobre o volume de enchimento e possa acomodar diferentes tamanhos e formatos de garrafas. Algumas máquinas vêm com configurações ajustáveis que permitem ajustar o processo de envase para atender às suas necessidades específicas.

Facilidade de uso e manutenção também são considerações essenciais ao escolher uma máquina de envase semiautomática de garrafas de noz em pó. Uma máquina fácil de usar ajudará a reduzir o tempo de inatividade e a aumentar a produtividade, permitindo que os operadores configurem e operem a máquina rapidamente. Procure recursos como controles intuitivos, componentes fáceis de limpar e recursos de troca rápida. Além disso, considere a disponibilidade de peças de reposição e suporte técnico para garantir que sua máquina possa ser facilmente mantida e reparada quando necessário.

O custo é outro fator crucial a considerar ao selecionar uma máquina semiautomática de envase de garrafas de pó de noz para o seu negócio. Embora seja essencial manter-se dentro do orçamento, também é importante considerar os custos a longo prazo associados à máquina, tais como manutenção, reparações e consumo de energia. Compare o custo inicial da máquina com seu valor geral e desempenho para determinar o melhor investimento para o seu negócio.

Concluindo, escolher a máquina semiautomática de envase de garrafas em pó de noz certa para o seu negócio requer uma consideração cuidadosa de fatores como capacidade de produção precisão, facilidade de uso, manutenção e custo. Ao avaliar esses fatores e selecionar uma máquina que atenda às suas necessidades específicas, você pode melhorar a eficiência e a produtividade do seu processo de embalagem e garantir a qualidade dos seus produtos. Reserve um tempo para pesquisar e comparar diferentes máquinas para encontrar a que melhor se adapta ao seu negócio.

Dicas de manutenção para máquina de engarrafamento semiautomática de nozes em pó

Manter uma máquina semiautomática de envase de garrafas em pó de noz é essencial para garantir seu desempenho e longevidade ideais. A manutenção regular não só evita quebras e reparos dispendiosos, mas também ajuda a manter a qualidade dos produtos envasados. Neste artigo, discutiremos algumas dicas importantes de manutenção para uma máquina semiautomática de envase de garrafas em pó de nozes.

Em primeiro lugar, é crucial limpar a máquina regularmente para evitar o acúmulo de resíduos de pó de nozes. Este resíduo pode entupir os componentes da máquina, causando ineficiência e possíveis danos. Use uma escova macia ou pano para remover qualquer resíduo de pó das superfícies da máquina, incluindo os bicos de enchimento, correias transportadoras e tremonhas. Além disso, certifique-se de limpar os filtros e telas da máquina para garantir o fluxo de ar adequado e evitar bloqueios.

Inspecione as peças móveis da máquina, como correias, correntes e engrenagens, em busca de sinais de desgaste. Substitua imediatamente quaisquer peças desgastadas ou danificadas para evitar maiores danos à máquina. Lubrifique regularmente as peças móveis da máquina para reduzir o atrito e garantir um funcionamento suave. Utilize um lubrificante de alta qualidade recomendado pelo fabricante para prolongar a vida útil dos componentes da máquina.

Verifique se há sinais de danos ou mau funcionamento nos componentes elétricos da máquina, como interruptores, sensores e fiação. Conexões soltas ou fiação danificada podem causar problemas elétricos e potencialmente levar a uma avaria. Certifique-se de apertar todas as conexões soltas e substituir qualquer fiação danificada para garantir que o sistema elétrico da máquina esteja funcionando corretamente.

Calibre as configurações da máquina regularmente para garantir o enchimento preciso do pó de nozes nas garrafas. Use uma escala calibrada para verificar a precisão da máquina e ajustar as configurações conforme necessário. A calibração inadequada pode resultar em enchimento insuficiente ou excessivo de garrafas, levando ao desperdício de produto e à insatisfação do cliente. A calibração regular garante o enchimento consistente e preciso das garrafas, mantendo a qualidade dos produtos envasados.

Inspecione as vedações e juntas da máquina em busca de sinais de desgaste. Vedações e juntas danificadas podem causar vazamentos, causando derramamento e contaminação do produto. Substitua imediatamente quaisquer vedações e juntas danificadas para evitar vazamentos e garantir o funcionamento adequado da máquina.

Por último, agende verificações de manutenção regulares com um técnico qualificado para inspecionar a máquina completamente e resolver quaisquer problemas potenciais. Um técnico profissional pode identificar e resolver quaisquer problemas subjacentes antes que se transformem em avarias graves. Verificações regulares de manutenção também podem ajudar a identificar quaisquer peças desgastadas que precisem de substituição, evitando paradas inesperadas e reparos dispendiosos. . Limpeza regular, inspeção, lubrificação, calibração e substituição de peças desgastadas são tarefas importantes de manutenção que devem ser realizadas regularmente. Seguindo essas dicas de manutenção, você pode prolongar a vida útil da sua máquina, evitar quebras e manter a qualidade dos produtos envasados. Lembre-se de que uma máquina bem conservada é uma máquina confiável.