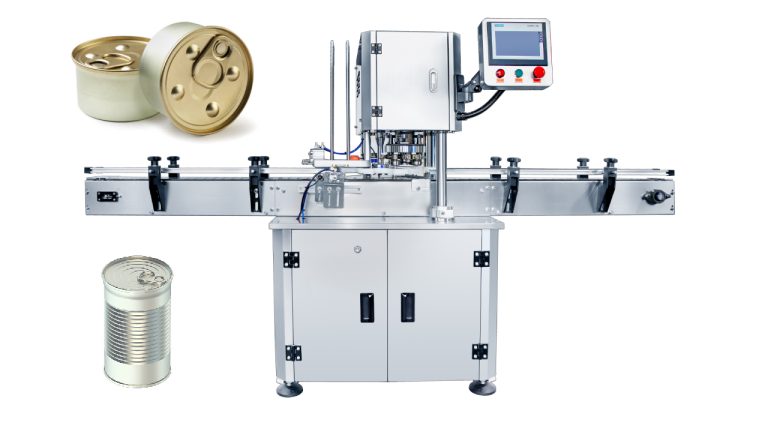

In the world of snack packaging, the fully automatic can closing machine has emerged as a game-changer.

This advanced piece of equipment offers numerous benefits that streamline the packaging process and enhance product quality. One of the standout features of the fully automatic can closing machine is its speed and efficiency. It can seal a large number of snack cans in a short period, significantly increasing production output.

The accuracy and consistency of the sealing process are crucial. Every can is closed with precision, ensuring a tight and reliable seal that protects the snacks from air, moisture, and contaminants. This helps maintain the freshness and flavor of the snacks for an extended period.

The machine is designed to handle a variety of can sizes and shapes, providing flexibility for snack manufacturers to meet different market demands. It can adapt seamlessly to changes in production requirements, making it a versatile choice.

Automation also reduces the reliance on manual labor, minimizing the potential for human error and improving overall packaging quality. The consistent performance of the machine ensures that each can is closed to the same high standards.

Furthermore, the fully automatic can closing machine often comes with advanced monitoring and control systems. These allow operators to closely monitor the packaging process, make real-time adjustments, and detect any potential issues promptly.

In terms of maintenance, modern designs aim to make it straightforward and hassle-free. Regular servicing and proper upkeep can ensure the machine’s longevity and continued efficient operation.

The use of a fully automatic can closing machine for snack cans not only improves the packaging process but also contributes to the overall success and competitiveness of snack brands in the market.

Stay tuned to our blogs for more in-depth looks at the latest advancements in packaging technology for the snack industry!